As for competitive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we are the lowest around for Factory Cheap Hot Din3352 F4 Ductile Cast Iron Resilient Flanged Gate Valve Dn50, Our firm is performing with the procedure principle of “integrity-based, cooperation created, people oriented, win-win cooperation”. We hope we can easily have a pleasant partnership with businessman from all around the environment.

As for competitive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we are the lowest around for Ductile Iron Gate Valve, Flange Gate Valve, Resilient Gate Valve, Our company adheres to the spirit of “lower costs, higher quality, and making more benefits for our clients”. Employing talents from the same line and adhering to the principle of “honesty, good faith, real thing and sincerity”, our company hopes to gain common development with clients from both at home and abroad!

Technical� data�

|

PN(MPa) Nominal pressure |

1.0 |

1.6 |

|

(MPa) Strength test� |

1.5 |

2.4 |

|

(MPa) Seal test |

1.1 |

1.76 |

|

Working temperature |

¡Ü120 | |

|

Suitable media |

water, oil , gas and non corrosive media |

|

Meterial of main parts

|

parts |

material |

|

body |

cast iron, ductile iron,cast steel |

|

seat |

EPDM, NBR,VITON, PTFE |

|

disc |

nickel ductile iron,AI bronze, stainless steel |

|

stem |

carbon steel, stainless steel |

|

bushing |

PTFE |

|

“O” ring |

PTFE |

|

pin |

stainless steel |

|

key |

stainless steel |

� Executive� Standard:

| Design Standard | EN 593 , MSS SP67� � � API 609� � BS5155 |

| Inspection & Test | API 598 � ISO 5208 � EN 12266 |

| End Standard | ANSI B16.1 CL. 125LB & B16.5 CL. 150LBAS 2129 Table D & E� � � BS 10 Table D & EDIN 2501 PN6, PN10 & PN16EN 1092 PN6, PN10 & PN16ISO 2531 PN6, PN10 & PN16ISO 7005 PN6, PN10 & PN16KS B 1511 / JIS B 2210 5K & 10KMSS SP44 CL. 150LB� � AWWAC207SABS 1123 Table 1000/3 & Table 1600/3 |

| Face to Face | ISO 5752 , EN 558 , MSS SP67 and API 609� � DIN3202 |

| Top Flange | ISO 5211 |

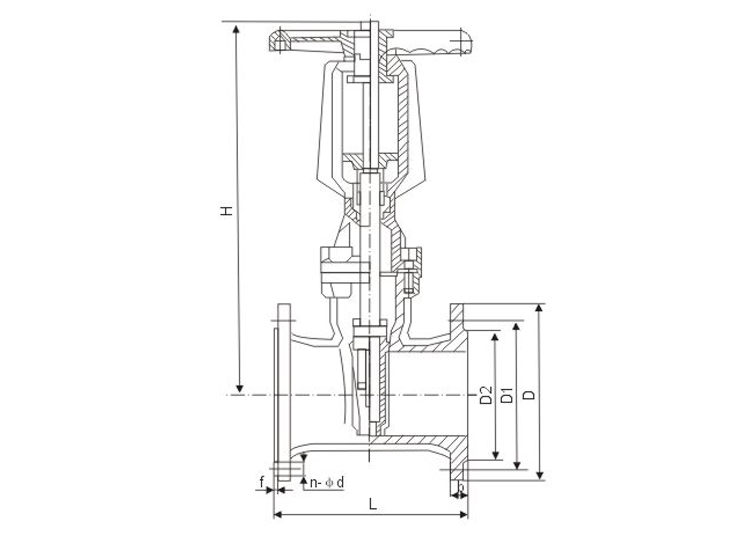

Main dimensions and weight

| DN(mm) | L | H | D | D1 | D2 | n-�ød | b | f | weight | |||||

| 1.0 | 1.6 | 1.0 | 1.6 | 1.0 | 1.6 | 1.0 | 1.6 | 1.0 | 1.6 | |||||

| 40 | 165 | 300 | 150 | 150 | 110 | � 110 | � 84 | � 84 | � 4-�ø18 | � 4-�ø18 | � 19 | � 19 | 3 | � 6.5 |

| 50 | 178 | 340 | 165 | 165 | � 125 | � 125 | � 99 | � 99 | � 4-�ø18 | � 4-�ø18 | � 20 | � 19 | � 3 | � 8 |

| 65 | 190 | 370 | 185 | 185 | � 145 | � 145 | � 118 | � 118 | � 4-�ø18 | � 4-�ø18 | � 20 | � 19 | � 3 | � 12 |

| 80 | 203 | 410 | 200 | 200 | � 160 | � 160 | � 132 | � 132 | � 8-�ø18 | � 8-�ø18 | � 22 | � 19 | � 3 | � 20 |

| 100 | 229 | 450 | 220 | 220 | � 180 | � 180 | � 156 | � 156 | � 8-�ø18 | � 8-�ø18 | � 24 | � 19 | � 3 | � 26 |

| 125 | 254 | 480 | 250 | 250 | � 210 | � 210 | � 184 | � 184 | � 8-�ø18 | � 8-�ø18 | � 26 | � 19 | � 3 | � 35 |

| 150 | 267 | 550 | 285 | 285 | � 240 | � 240 | � 211 | � 211 | � 8-�ø23 | � 8-�ø23 | � 26 | � 19 | � 3 | � 48 |

| 200 | 229 | 630 | 340 | 340 | � 295 | � 295 | � 266 | � 266 | � 8-�ø23 | � 12-�ø23 | � 26 | 20 | � 3 | � 75 |

| 250 | 330 | 750 | 395 | 405 | � 350 | � 355 | � 319 | � 319 | � 12-�ø23 | � 12-�ø28 | � 28 | � 22 | � 3 | � 120 |

| 300 | 356 | 820 | 445 | 460 | � 400 | � 410 | � 370 | � 370 | � 12-�ø23 | � 12-�ø28 | 28 | 24.5 | � 4 | � 165 |

| 350 | 381 | 980 | 505 | 520 | � 460 | � 470 | � 429 | � 429 | � 16-�ø23 | � 16-�ø28 | � 30 | � 26.5 | 4 | � 230 |

| 400 | 406 | 1010 | 565 | 580 | � 515 | � 525 | � 480 | � 480 | � 16-�ø28 | � 16-�ø31 | � 32 | � 28 | � 4 | � 270 |

| 450 | 432 | 1270 | 615 | 640 | � 565 | � 585 | � 530 | � 548 | � 20-�ø28 | � 20-�ø31 | � 32 | � 30 | � 4 | � 450 |

| 500 | 457 | 1270 | 670 | 715 | � 620 | � 650 | � 582 | � 609 | � 20-�ø28 | � 20-�ø34 | � 34 | � 31.5 | � 4 | � 590 |

| 600 | 508 | 1390 | 780 | 840 | � 725 | � 770 | � 682 | � 720 | � 20-�ø31 | � 20-�ø37 | � 36 | � 36 | � 5 | � 619 |

Send your message to us:

-

Hot New Products China Ductile Cast Iron Wafer ...

-

OEM/ODM China 2pc Wcb Material Screwed End 1000...

-

Renewable Design for China DN25 Double Cast Iro...

-

OEM/ODM Supplier China Pn16 DN200 High Temperat...

-

Wholesale OEM Chemical Resistant Ptfe Valve Seat

-

OEM Supply China Esg DN32 Replacement for VIP A...