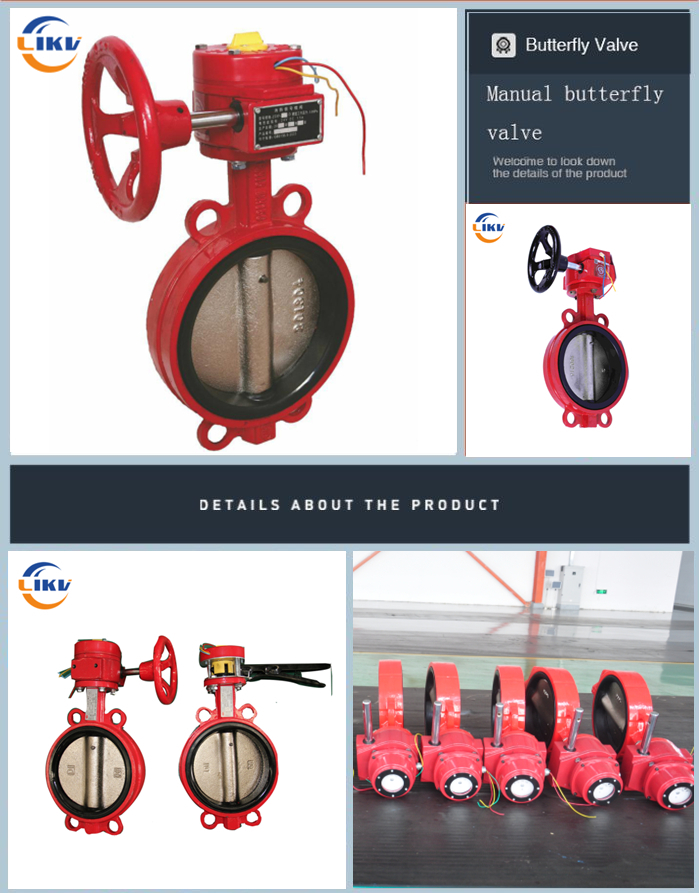

BWSX mid-line butterfly valve is a mid-line butterfly valve developed by introducing advanced technology from abroad. BWSX mid-line butterfly valve has the advantages of simple structure, reliable sealing, easy opening, long service life and convenient maintenance. Therefore, it is widely used in various pipelines of water supply and drainage system, building fire protection system, especially in fire protection pipelines.

Features:

1.Small in size and light in weight. Easy instllation and rrintenance. It can be mounted wherever nedded.

2.Sipie and compact construction, quick 90 degrees on-off operation.

3.Miniminzed operating torque, energy saving.

4.Bubbles-tight sealing with no leakage under the pressure test.

5.Wide selection of materials, applicable for various mdeium.

Specification

|

DN(mm)� Nominal diameter |

50 (2") -250 (10") |

||

|

PN (MPa)� Nominal pressure |

1.0 |

1.6 |

|

|

Testing pressure |

Shell |

1.5 |

2.4 |

|

Sealing |

1.1 |

1.76 |

|

|

¡ãC Working temperature |

-15~+150 |

||

|

Suitable mediums |

water.sewage, sea water, air, steam, food, medicine, etc. � |

||

|

� Microswitch capacity |

AC 220V 1A DC 30V 0.5A |

||

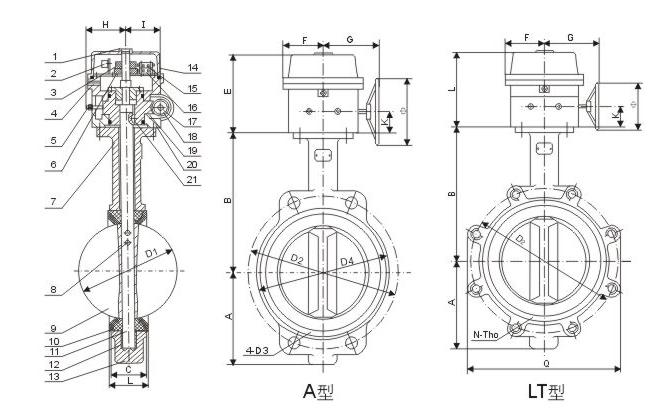

Dimension

Main dimensions and weight

| DN | A | B | C | D1 | D2 | D3 | D4 | E | K | L | �ø | a¡ã | Weight | |

| mm | inch | |||||||||||||

| 50 | 2" | 80 | 161 | 42 | 52.9 | 120 | 23 | 100 | 150 | 35 | 45 | 150 | 45 | 8 |

| 65 | 2.5" | 89 | 175 | 44.7 | 64.5 | 136.2 | 26.5 | 120 | 150 | 35 | 47.6 | 150 | 45 | 8.7 |

| 80 | 3" | 95 | 181 | 45.2 | 78.8 | 160 | 18 | 127 | 150 | 35 | 49 | 150 | 22.5 | 9.1 |

| 100 | 4" | 114 | 200 | 52.1 | 104 | 185 | 24.5 | 156 | 150 | 35 | 54.7 | 150 | 22.5 | 10.4 |

| 125 | 5" | 127 | 213 | 54.4 | 123.3 | 215 | 23 | 190 | 150 | 35 | 58 | 150 | 22.5 | 12.5 |

| 150 | 6" | 139 | 226 | 55.8 | 155.6 | 238 | 25 | 212 | 150 | 35 | 58.6 | 150 | 22.5 | 13.3 |

| 200 | 8" | 175 | 260 | 60.6 | 202.5 | 295 | 25/23 | 268 | 150 | 40 | 63.4 | 200 | 22.5/15 | 22.2 |

| 250 | 10" | 203 | 292 | 65.6 | 250.5 | 357 | 29 | 325 | 150 | 40 | 70 | 200 | 15 | 28.2 |

| DN | A | B | C | D1 | D2 | N | Th0 | Q | E | K | L | �ø | Weight | |

| mm | inch | |||||||||||||

| 50 | 2¡° | 80 | 161 | 42 | 52.9 | 125 | 4 | M16 | 118 | 150 | 35 | 45 | 150 | 9.3 |

| 65 | 2.5¡± | 89 | 175 | 44.7 | 64.5 | 145 | 4 | M16 | 137 | 150 | 35 | 47.6 | 150 | 9.7 |

| 80 | 3¡° | 95 | 181 | 45.2 | 78.8 | 160 | 8 | M16 | 178 | 150 | 35 | 49 | 150 | 10.2 |

| 100 | 4¡± | 114 | 200 | 52.1 | 104 | 180 | 8 | M16 | 206 | 150 | 35 | 54.7 | 150 | 14.5 |

| 125 | 5¡° | 127 | 213 | 54.4 | 123.3 | 210 | 8 | M16 | 238 | 150 | 35 | 58 | 150 | 16.4 |

| 150 | 6¡± | 139 | 226 | 55.8 | 155.6 | 240 | 8 | M16 | 266 | 150 | 35 | 58.6 | 150 | 19.7 |

| 200 | 8¡° | 175 | 260 | 60.6 | 202.5 | 295 | 8/12 | M20 | 329 | 150 | 40 | 63.4 | 200 | 27.2 |

| 250 | 10¡± | 203 | 292 | 65.6 | 250.5 | 350/355 | 12 | M20/M24 | 393 | 150 | 40 | 70 | 200 | 35.8 |

Qualification certificate

American LIKE valves is a global supplier of flow control products£¬solution and services with a diverse range of products, for infrastructure and industrial fluid control. Our solution is an integral key part of the pipeline management solution, adopting advanced mechanical technology and automation system, so that the products always maintain excellent quality, and responding to customer needs correctly and fast. LIKE valve's customers and markets cover water supply and drainage, water treatment, heating, construction, fire fighting, HVAC systems, power plants, petrochemical, natural gas pipelines, ships and other fields.

LIKE valves always adhere to the quality policy of "quality is the life of products, products are the life of LIKE", have been passed ISO9001, ISO14001, OHSAS18001, TS, API, CE, ROHS£¬CCC� certificate of professional testing institutions. We take customer satisfaction as the purpose, take our mission to realize the value by supply excellent service to our customers, strive to do even better on each product, each service, to provide continuous guarantee for customers all over the world.

In 2016, LIKE valve products entered Chinese market. In 2017, LIKE Valve was registered Like Valves (Tianjin) Co., LTD. in China, a joint venture of the United States and China, dedicated to serving customers in the Asia-Pacific region and China.

LIKE valve adhering to the concept of "integrity, innovation, cooperation and mutual benefit", building our brand with product quality and customer satisfaction; improving and surpass ourselves with unremitting pursuit and sustainable development. "LIKE Dream" will contribution to "China Dream" more wonderful!

Factory