Valve feem ntau siv cov ntaub ntawv tsis yog xim hlau xyuas cov kev sib txuas ntawm lub tshuab hluav taws xob thiab txhua lub valve

Ethylene propylene roj hmab rooj zaum ntsuas kub yog -28 ¡æ ~ 120¡æ. EPDM sawv cev rau terpolymer ntawm ethylene, propylene, thiab diene, feem ntau hu ua EPT Nordell. Zoo heev ozone kuj thiab huab cua tsis kam, zoo hluav taws xob rwb thaiv tsev kev ua tau zoo, zoo tiv thaiv rau polar capacitors thiab inorganic media. Yog li ntawd, nws tuaj yeem siv rau hauv HVAC kev lag luam, dej, phosphate ester, cawv, ethylene glycol, thiab lwm yam. Ethylene propylene roj hmab rooj zaum tsis pom zoo rau siv hauv HYDROCARBON organic SOLVENTS THIAB OILS, chlorINATED HYDROCARBONS, lwm yam, turpent OILS.

Valve feem ntau siv cov khoom tsis yog xim hlau

Nyob zoo, nitrile roj hmab

Nitrile roj hmab rooj zaum ntsuas kub yog -18 º C txog 100 ¡ã C. Kuj feem ntau hu ua, NITRILE, lossis HYCAR. Nws yog cov khoom siv roj hmab thoob ntiaj teb haum rau dej, roj, roj thiab roj, roj av (tshwj tsis yog roj av nrog cov khoom ntxiv), cawv thiab ethylene glycol, roj av liquefied, propane thiab butane, roj roj thiab ntau lwm yam xov xwm. Nws kuj muaj qhov hnav tsis kam thiab deformation tsis kam. Khoom noj khoom haus qib (FG) nitrile roj hmab rooj zaum ntsuas kub yog -18¡æ txog 82¡æ. Nws muaj pes tsawg leeg ua raws li CFR Standard Part 21, Tshooj 177.2600. Nws tuaj yeem siv tib yam li cov roj hmab nitrile tsis tu ncua tab sis yuav tsum tau txais kev pom zoo los ntawm FDA.

Ethylene propylene roj hmab EPDM

Ethylene propylene roj hmab rooj zaum ntsuas kub yog -28¡æ ~ 120¡æ. EPDM sawv cev rau terpolymer ntawm ethylene, propylene, thiab diene, feem ntau hu ua EPT Nordell. Zoo heev ozone kuj thiab huab cua tsis kam, zoo hluav taws xob rwb thaiv tsev kev ua tau zoo, zoo tiv thaiv rau polar capacitors thiab inorganic media. Yog li ntawd, nws tuaj yeem siv rau hauv HVAC kev lag luam, dej, phosphate ester, cawv, ethylene glycol, thiab lwm yam. Ethylene propylene roj hmab rooj zaum tsis pom zoo rau siv hauv HYDROCARBON organic SOLVENTS THIAB OILS, chlorINATED HYDROCARBONS, lwm yam, turpent OILS.

Khoom noj khoom haus qib ethylene propylene roj hmab rooj zaum ntsuas kub yog -28¡æ ~ 120¡æ. Nws muaj pes tsawg leeg ua raws li CFR Standard Part 21, Tshooj 177.2600. Nws tuaj yeem siv tib yam li cov roj hmab nitrile tsis tu ncua tab sis yuav tsum tau txais kev pom zoo los ntawm FDA.

PTFE khoom

Teflon lub rooj ntsuas kub yog -32 º C txog 200 º C. Zoo heev tiv taus kub thiab tshuaj lom neeg corrosion. Vim yog qhov ntom ntom ntawm polytetrafluoroethylene, permeability zoo heev, tab sis kuj tuaj yeem tiv thaiv corrosion ntawm cov tshuaj lom neeg feem ntau.

Conductive TEFLON yog ib qho kev hloov kho TEflON cov khoom uas tso cai rau tam sim no mus rau hauv ob sab phlu kom tshem tawm cov rwb thaiv tsev ntawm TEflON. Vim nws cov conductivity, conductive polytetrafluoroethylene tsis tuaj yeem kuaj los ntawm hluav taws xob spark.

Reinforced polyteflon RTFE

RTFE yog kev hloov kho ntawm PTFE cov khoom. Txawm hais tias kev sib txhuam coefficient ntawm ntshiab PTFE yog tsawg heev (0.02 ~ 0.04), tab sis qhov hnav yog qhov zoo, thiab vim nws yooj yim nkag, cov khoom siv tsis zoo, tsis tshua muaj peev xwm, tsis muaj qhov ruaj khov thiab lwm yam ntxwv, raws li cov khoom siv sib txhuam zoo heev. txwv. Tsuas yog kev hloov kho, los ntawm cov txheej txheem ntawm cov khoom sib xyaw kom tau raws li cov kev cai tshwj xeeb ntawm cov khoom hnav-tiv taus sealing nyob rau hauv txhua qhov chaw ntawm lub neej, hauv kev txhim kho qhov hnav tsis kam ntawm PTFE, tuaj yeem tov nrog qee yam hnav-tiv taus xws li iav fiber, carbon fiber. , graphite, molybdenum disulfide, bronze hmoov thiab qee cov organic tebchaw, Cov pob qij txha mesh yog tsim nyob rau hauv cov txheej txheem PTFE los txhim kho qhov tawv nqaij, thermal conductivity, creep resistance, thiab hnav tsis kam.

Fluorine roj hmab Viton

Qhov ntsuas kub ntawm fluorine roj hmab rooj zaum yog -18¡æ ~ 150¡æ. Viton yog lub npe lag luam ntawm DuPont Tuam Txhab, thiab Fluorel yog ib lub npe lag luam sib npaug rau fluorine roj hmab ntawm 3M Tuam Txhab. Cov khoom no muaj qhov kub thiab txias tsis kam thiab zoo heev tshuaj corrosion kuj. Haum rau cov khoom siv hydrocarbon, tsis tshua muaj siab thiab siab concentration ntawm cov ntxhia acids, tab sis tsis nyob hauv chav dej thiab dej (tsis muaj dej tsis kam).

Ultra siab molecular hnyav polyethylene UHMWPE

Ultra-high molecular hnyav polyethylene rooj zaum yog ntsuas los ntawm -32 ¡ã C mus rau 88 º C. Cov khoom no muaj qhov kub thiab txias tsis kam zoo dua li PTFE, tab sis tseem muaj tshuaj tiv thaiv zoo heev. Uhmwpe kuj muaj qhov hnav tsis kam thiab corrosion kuj, thiab tuaj yeem siv rau hauv cov xwm txheej hnyav hnyav.

Silicone tooj liab roj hmab Silicone

Copper silicone roj hmab yog ib qho polymer nrog cov organic pawg, nws cov saw tseem ceeb yog tsim los ntawm silicon thiab oxygen atoms. Qhov ntsuas kub yog li ntawm -100 ¡ã C mus rau 300 º C. Nws muaj qhov kub thiab txias tsis kam, zoo hluav taws xob rwb thaiv tsev kev ua tau zoo thiab cov tshuaj inertness loj. Haum rau cov organic acid thiab tsawg concentration ntawm inorganic acid, dilute alkali thiab concentrated alkali. Disadvantages: tsawg mechanical zog. Yuav tsum tau kho tom qab vulcanization.

Graphite Cov

Graphite yog siv lead ua ntawm cov pa roj carbon, yog cov khoom siv tsis yog xim hlau, xim grey xim, muag muag zoo, nrog cov xim hlau. Mohs hardness yog 1 ~ 2, lub ntiajteb txawj nqus tshwj xeeb yog 2.2 ~ 2.3, thiab qhov ntom ntom feem ntau yog 1.5 ~ 1.8. Nws muaj qhov kub thiab txias tsis kam, oxidation tsis kam, corrosion kuj, thermal shock resistance, siab zog, zoo toughness, siab self-lubricating zog, muaj zog thermal conductivity, hluav taws xob conductivity thiab lwm yam tshwj xeeb lub cev thiab tshuaj. Nws muaj tshwj xeeb oxidation tsis kam, nws tus kheej-lubricity thiab plasticity ntawm qhov kub thiab txias, thiab zoo hluav taws xob, thermal thiab adhesion zog. Nws tuaj yeem siv los ua tus muab tub lim lossis kev ua tau zoo IMPROver rau roj hmab, yas thiab ntau yam khoom siv los txhim kho cov hnav tsis kam, compression tsis kam lossis conductivity ntawm cov ntaub ntawv. Lub valve gasket, ntim thiab lub rooj zaum feem ntau yog ua los ntawm graphite.

Graphite ntawm siab melting point, mus rau 3000 ¡æ nyob rau hauv lub nqus tsev vacuum yog yuav pib soften tends rau yaj lub xeev, graphite evaporated sublimation mus rau 3600 ¡æ, cov khoom siv nyob rau hauv lub kub kub lub zog yuav txo qis maj mam, thaum lub graphite nyob rau hauv lub rhuab mus rau 2000. ¡ æ, nws lub zog yog qhov kub ib txwm ob npaug, tab sis qhov sib txawv ntawm oxidation tsis kam ntawm graphite oxidation tus nqi tau maj mam nce nrog qhov kub thiab txias.

Lub thermal conductivity thiab hluav taws xob conductivity ntawm graphite yog siab heev, nws conductivity yog 4 lub sij hawm siab tshaj stainless hlau, 2 lub sij hawm siab tshaj carbon steel, 100 lub sij hawm siab tshaj cov non-hlau. Nws cov thermal conductivity, tsis tsuas yog ntau tshaj li cov hlau, hlau, txhuas thiab lwm yam ntaub ntawv hlau, tab sis kuj nrog rau qhov kub thiab txias ua rau cov thermal conductivity txo, uas txawv los ntawm cov ntaub ntawv hlau, ntawm qhov kub thiab txias, graphite txawm nyhav rau adiabatic xeev. Yog li ntawd, nyob rau hauv ultra-siab kub tej yam kev mob, graphite rwb thaiv tsev kev ua tau zoo heev txhim khu kev qha. Graphite muaj lubricity zoo thiab plasticity, graphite kev sib txhuam coefficient tsawg dua 0.1, graphite tuaj yeem tsim rau hauv daim ntawv permeable, thawj theem ntawm graphite hardness loj heev, txawm tias cov cuab yeej pob zeb diamond yog qhov nyuaj rau kev ua haujlwm. Graphite muaj tshuaj stability, acid kuj, alkali tsis kam, tsis kam mus rau organic solvents corrosion. Vim yog cov khoom tshwj xeeb zoo tshaj plaws ntawm graphite, hauv kev siv niaj hnub siv tau zoo heev.

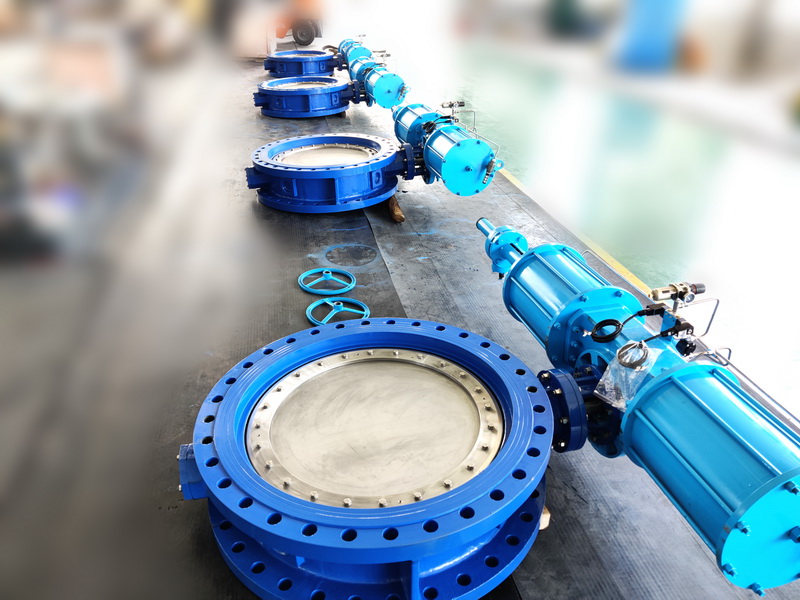

Hom kev sib txuas ntawm hluav taws xob actuator thiab txhua lub valve

Cov hluav taws xob actuator feem ntau yog txuam nrog lub valve, uas yog siv rau hauv kev tswj tsis siv neeg. Muaj ntau ntau hom hluav taws xob actuators, uas txawv nyob rau hauv hom kev ua. Piv txwv li, lub angular stroke hluav taws xob actuator yog qhov tso zis angular torque, thaum lub zog stroke hluav taws xob ncaj qha yog qhov tso zis tawm thrust. Hom hluav taws xob actuator nyob rau hauv daim ntawv thov system yuav tsum raug xaiv raws li kev xav tau ntawm lub valve.

Txoj kev sib txuas

I. Flange kev twb kev txuas:

Qhov no yog hom kev sib txuas feem ntau siv hauv cov li qub. Raws li cov duab ntawm qhov sib koom ua ke, nws tuaj yeem muab faib ua cov hauv qab no:

1. Hom du: siv rau cov li qub uas tsis tshua muaj siab. Kev ua haujlwm yooj yim

2, concave thiab convex hom: siab ua hauj lwm siab, yuav siv tau nyob rau hauv lub hard washer

3. Tenon thiab groove hom: gasket nrog cov yas deformation loj tuaj yeem siv rau hauv cov xov xwm corrosive, thiab cov nyhuv sealing zoo dua.

4, trapezoidal groove hom: nrog oval hlau nplhaib ua lub tshuab ntxhua khaub ncaws, siv rau hauv kev ua haujlwm siab ntawm 64 kg / cm2 valve, los yog kub kub valve.

5, hom lens: lub tshuab ntxhua khaub ncaws yog lub lens zoo, ua los ntawm hlau. Rau siab siab VALVES nrog kev ua haujlwm siab ntawm 100 kg / CM2, lossis siab kub li qub.

6, O nplhaib hom: Qhov no yog ib tug tshiab flange kev twb kev txuas daim ntawv, nws yog tsim nrog cov tsos ntawm ntau yam roj hmab O nplhaib, nws yog nyob rau hauv lub sealing nyhuv ntawm daim ntawv txuas.

Thib ob, thread kev sib txuas:

Qhov no yog ib txoj kev sib txuas yooj yim thiab feem ntau siv nrog cov li qub me me. Muaj ob qhov xwm txheej ntxiv:

1, ncaj qha sealing: cov xov sab hauv thiab sab nraud ncaj qha ua lub luag haujlwm ntawm kev sib khi. Txhawm rau kom ntseeg tau tias qhov sib koom ua ke tsis xau, feem ntau nrog cov roj txhuas, linoleum thiab PTFE raw khoom ntim; Ptfe raw khoom siv, siv qhov chaw muaj koob muaj npe; Cov khoom siv no muaj kev tiv thaiv corrosion zoo, sealing nyhuv, yooj yim rau siv thiab khaws cia, disassembly, tuaj yeem raug tshem tawm tag nrho, vim nws yog cov yeeb yaj kiab uas tsis muaj kuab lom, zoo dua cov roj txhuas, linoleum.

2. Indirect sealing: lub zog ntawm cov ntsia hlau nruj yog hloov mus rau lub tshuab ntxhua khaub ncaws ntawm ob lub dav hlau, kom lub tshuab ntxhua khaub ncaws ua lub luag haujlwm sealing.

Peb, daim npav lub tes tsho txuas:

Lub hauv paus ntsiab lus ntawm kev sib txuas thiab kev sib khi ntawm lub tes tsho clamping yog tias thaum cov txiv ntoo tau nruj, lub tes tsho clamping nyob rau hauv siab, kom nws cov ntug tom rau hauv cov phab ntsa ntawm cov yeeb nkab, thiab lub tes tsho clamping lub khob hliav qab yog nyob ze rau ntawm lub cev sib koom ua ke. nyob rau hauv siab, yog li nws muaj peev xwm ntseeg tau los tiv thaiv to.

Qhov zoo ntawm hom kev sib txuas no yog:

1, me me, lub teeb yuag, qauv yooj yim, yooj yim disassembly;

2, kev sib txuas muaj zog, kev siv ntau yam, tuaj yeem tiv taus siab (1000 kg / cm2), kub siab (650¡æ) thiab poob siab

3, tuaj yeem xaiv ntau yam khoom siv, haum rau kev tiv thaiv corrosion;

4, machining qhov yuav tsum tau tsis siab; Yooj yim rau nruab ntawm qhov siab siab.

Daim ntawv txuas lub tes tsho clamping tau siv nyob rau hauv qee qhov me me txoj kab uas hla valve khoom hauv Suav teb.

Plaub, clamp kev twb kev txuas:

Qhov no yog ib txoj kev sib txuas ceev uas yuav tsum tau tsuas yog ob lub bolts nkaus xwb thiab tsim nyog rau kev tshem tawm qis qis qis qis.

Tsib, kev sib txuas ntawm tus kheej-tightening:

Saum toj no txhua yam ntawm cov ntaub ntawv kev twb kev txuas, yog siv los ntawm sab nraud quab yuam los offset lub siab ntawm nruab nrab, kom ua tiav sealing. Cov hauv qab no piav qhia txog ib hom kev sib txuas ntawm tus kheej nruj uas siv lub siab nruab nrab. Nws lub nplhaib sealing yog ntsia rau hauv lub khob hliav qab, nrog rau nruab nrab sab nraud rau hauv ib lub kaum ntse ntse, nruab nrab siab mus rau lub khob hliav qab, thiab xa mus rau lub nplhaib sealing, nyob rau hauv ib qho ntawm lub kaum sab xis ntawm lub khob hliav qab, tsim ob yam khoom, ib qho sib npaug rau txoj kab nruab nrab ntawm lub valve lub cev sab nraud, lwm qhov siab mus rau sab hauv phab ntsa ntawm lub cev valve. Cov khoom tom kawg yog lub zog ntawm tus kheej nruj. Qhov siab dua qhov nruab nrab, qhov ntau dua tus kheej-tightening quab yuam. Yog li no hom kev sib txuas yog tsim rau siab siab li qub. Nws txuag tau ntau ntawm cov khoom siv thiab kev ua haujlwm ntau dua li kev sib txuas flanged, tab sis kuj yuav tsum muaj qee yam ntawm preload, kom lub siab nyob rau hauv lub valve tsis siab, txhim khu kev qha siv. Lub valve ua los ntawm lub hauv paus ntsiab lus ntawm tus kheej nruj sealing feem ntau yog lub siab siab valve.

Muaj ntau hom kev sib txuas ntawm lub valve, piv txwv li, qee qhov tsis tas yuav tshem tawm lub valve me me, welded ua ke nrog cov yeeb nkab; Qee qhov tsis yog xim hlau, siv lub qhov (socket) txuas, thiab lwm yam. Cov neeg siv valve yuav tsum tau kho raws li cov xwm txheej tshwj xeeb.

Post lub sij hawm: Lub Xya hli ntuj-29-2022