Valve selection steps:

1. Define the use of the valve in the equipment or device, determine the working conditions of the valve: suitable medium, working pressure, working temperature and so on.

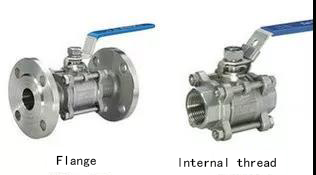

2. Determine the nominal diameter and connection mode of the pipe connecting with the valve: flange, thread, welding, jacket, quick-fixing, etc.

3. Determine the way to operate the valve: manual, electric, electromagnetic, pneumatic or hydraulic, electrical or hydraulic linkage, etc.

4. According to the medium conveyed by pipeline, working pressure and working temperature, the materials of valve shell and inner parts are selected: grey cast iron, malleable cast iron, nodular cast iron, carbon steel, alloy steel, stainless acid-resistant steel, copper alloy, etc.

5. Select the types of valves: closed-circuit valves, regulating valves, safety valves, etc.

6. Determine the types of valves: gate valves, globe valves, ball valves, butterfly valves, throttle valves, safety valves, pressure relief valves, steam traps, etc.

7. Determine the parameters of valves: For automatic valves, the allowable flow resistance, discharge capacity, back pressure, etc. are determined first according to different needs, and then the nominal diameter of pipeline and the diameter of valve seat hole are determined.

8. Determine the geometric parameters of the selected valve: length of structure, flange connection form and size, height direction of the valve after opening and closing, bolt hole size and number of connections, the size of the whole valve shape, etc.

9.Use the existing information: Valve product catalogue, valve product samples, etc. to select the appropriate valve products.

Valve selection basis:

1. The use, operating conditions and control mode of the selected valve.

2. Properties of working medium: working pressure, working temperature, corrosion performance, whether solid particles are contained, whether the medium is toxic, whether it is flammable, explosive medium, medium viscosity and so on.

3. Requirements for valve fluid characteristics: flow resistance, discharge capacity, flow characteristics, sealing grade, etc.

4. Installation dimension and outline dimension requirements: nominal diameter, connection mode with pipeline and connection dimension, outline dimension or weight limitation, etc.

5. Additional requirements for reliability of valve products, service life and explosion-proof performance of electric devices. (Attention should be paid when selecting parameters: if the valve is to be used for control purposes, additional parameters must be determined as follows: operation method, maximum and minimum flow requirements, pressure drop of normal flow, pressure drop at closure, maximum and minimum inlet pressure of the valve.)

5. Additional requirements for reliability of valve products, service life and explosion-proof performance of electric devices. (Attention should be paid when selecting parameters: if the valve is to be used for control purposes, additional parameters must be determined as follows: operation method, maximum and minimum flow requirements, pressure drop of normal flow, pressure drop at closure, maximum and minimum inlet pressure of the valve.)

According to the above-mentioned basis and steps for selecting valves, when selecting valves reasonably and correctly, it is necessary to have a detailed understanding of the internal structure of various types of valves in order to make the right choice for the preferred valves. The final control of the pipeline is the valve. Valve opener controls the flow pattern of medium in the pipeline. The shape of the valve runner makes the valve have certain flow characteristics. This must be taken into account when selecting the most suitable valve for installation in the pipeline system.

Post time: Jun-25-2019