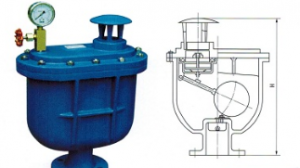

1、 Equipment introduction

The compound exhaust valve is a barrel shaped valve body, which mainly contains a group of stainless steel balls, rods and plugs. The valve is installed at the pump water outlet or in the water supply and distribution pipeline to discharge a large amount of air accumulated in the pipeline, or a small amount of air accumulated at a higher place of the pipeline to the atmosphere, so as to improve the service efficiency of the pipeline and the pump. Once there is negative pressure in the pipeline, the valve quickly inhales outside air to protect the pipeline from damage caused by negative pressure.

2、 How it works

When there is gas overflow in the system, the gas will climb up along the pipeline and finally gather at the highest point of the system, while the composite exhaust valve is generally installed at the highest point of the system. When the gas enters the composite exhaust valve cavity, it gathers at the upper part of the exhaust valve. With the increase of gas in the valve, the pressure rises. When the gas pressure is greater than the system pressure, the gas will make the water in the cavity drop and float After the gas is exhausted, the water level rises and the buoy also rises, and the exhaust port is closed. In the same way, when the negative pressure is generated in the system, the water level in the valve chamber will drop and the exhaust port will open. Because the external atmospheric pressure is greater than the system pressure at this time, the atmosphere will enter the system through the exhaust port to prevent the harm of negative pressure. If the valve cap on the valve body of the exhaust valve is tightened, the exhaust valve will stop exhausting. Generally, the valve cap should be open. The exhaust valve can also be used together with the block valve to facilitate the maintenance of the composite exhaust valve.

3、 Structure and Application

The valve is a barrel type valve body with stainless steel floating ball and plug inside.

The valve is installed at the outlet of the pump or in the water supply and distribution pipeline to remove a large amount of accumulated air in the pipeline, so as to improve the service efficiency of the water pipe and the pump. In case of negative pressure in the pipeline, the valve can quickly inhale air to protect the pipeline from damage caused by negative pressure.

4、 Advantages

The composite exhaust valve has reliable performance and can discharge a large amount of air in the pipeline and a small amount of gas in the system operation to the outside air at high speed. Easy maintenance, composite exhaust valve can be easily removed from the system for maintenance, and the water in the system will not flow out, so there is no need to empty the system. Only exhaust, no drainage, steam, water from the disc design uses a special structure to ensure that no drainage when exhaust. As long as there is pressure in the system, the compound exhaust valve will exhaust continuously.

5、 Technical parameters

1. Working pressure: 1.0 / 1.6Mpa

2. Medium: clear water

3. Service temperature: normal temperature

4. Valve body: HT200 / QT450

5. Floating ball and valve: 304 stainless steel

6. Sealing material: NBR

Post time: Apr-14-2021