Sticking for the principle of “Super Quality, Satisfactory service” ,We have been striving for being a superb small business partner of you for Professional Design China Slient Check Valve, Your inquiry will be highly welcomed and a win-win prosperous development are what we are expecting.

Sticking for the principle of “Super Quality, Satisfactory service” ,We have been striving for being a superb small business partner of you for China Lift Check Valve, Lifting Check Valve, Our company will continue to adhere to the ” superior quality, reputable, the user first ” principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

Technical parameters of hc41x energy saving silencing check valve

Nominal pressureú1.0~1.6MPa

Nominal diameterú40~600mm

Applicable medium: water and weak corrosive fluid

Applicable temperatureú0~80�æ Â

Flange standard£ºGB/T 17241.6¡¢GB/T 9113¡¢EN1092

Test standard£ºGB/T 13927¡¢API 598

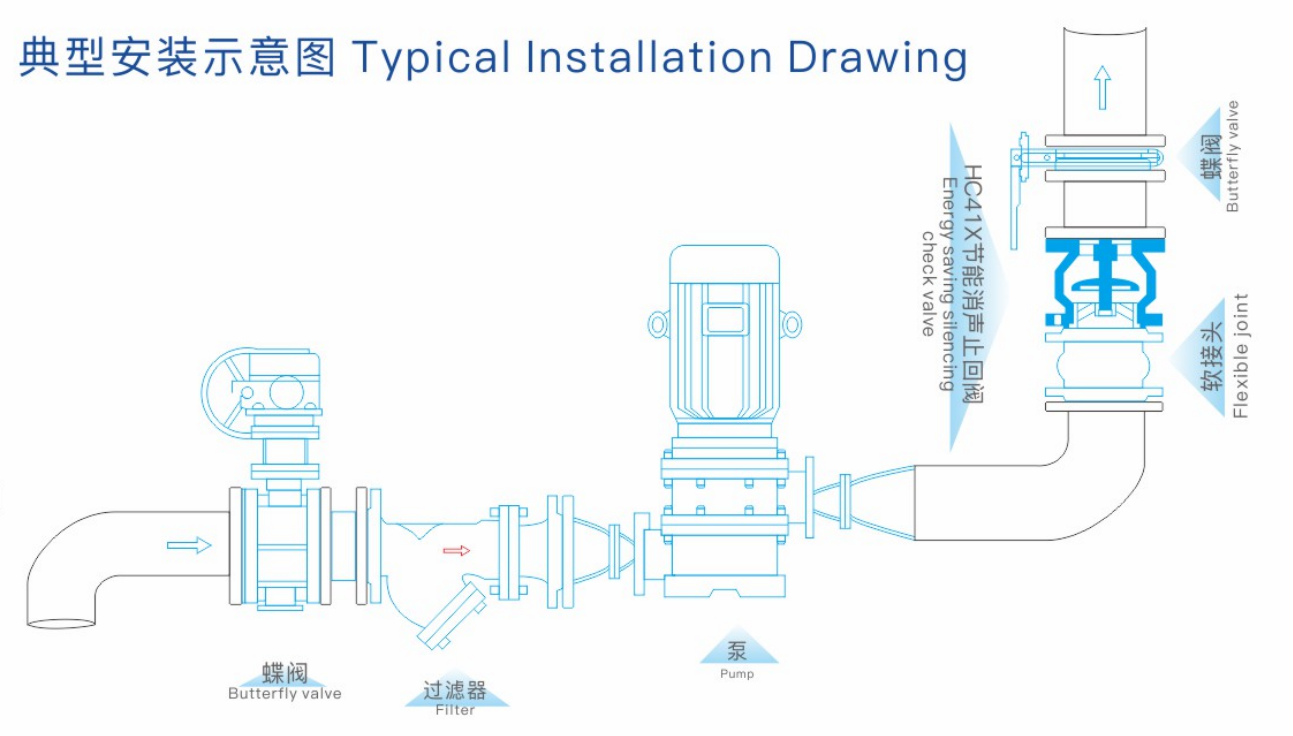

Typical installation diagram

Materials of main parts of hc41x energy saving and silencing check valve

| model | valve body | seal ring | Spring |

| HC41X-10/16 | Cast steel, ductile iron, carbon steel, stainless steel | Nitrile rubber | Stainless steel wire1Cr18Ni9Ti |

Main connection dimensions                                                         mm

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | 112 | 120 | 130 | 150 | 165 | 190 | 210 | 255 | 310 | 320 | 380 | 405 | 430 | 450 | 510 |