SOFT SEALING PTFE SEAT WAFER BUTTERFLY VALVE CHINA MANUFACTURER

Advantages of a�†Butterfly Valve

Butterfly valves are similar to ball valves but have more advantages. They are open and close very quickly when actuated pneumatically. The disc is lighter than a�†ball, and the valves require less structural support than a�†ball valve of comparable diameter. Butterfly valves are very precise, which makes them advantageous in industrial applications. They are quite reliable and require very little maintenance.

1. Turning on/off easily and rapidly with less force. Having less fluid resistance and can be operated frequently.

2. Simple structure, small size and short face to face dimension, which suitable for large diameter valves.

3. It can be used for transmitting mud, fewer liquids are stored at apertures of pipe.

4. Long service life. Standing the test of tens of thousands of opening/closing operations.

5. Butterfly valves have excellent regulation performance.

6. Small torque. The pressure on discs at the two sides of the spindle is almost equal, causing contrary torque. Thereby, the valves can be opened with less force.

7. Sealing face is generally med of rubber or plastic. So the butterfly valves can be with good sealing under low pressure.

Products Detailes

| working pressure | PN10, PN16 |

| testing pressure | shell: 1.5 times rated pressure

seat: 1.1 times rated pressure |

| working temperature | -10 °„C to 80°„C (NBR)

-10 °„C to 120°„C (EPDM) |

| suitable media | water, oil and gas |

| parts | material |

| body | cast iron, ductile iron, |

| seat | EPDM, NBR,VITON, PTFE |

| disc | nickel ductile iron,AI bronze, stainless steel |

| stem | carbon steel, stainless steel |

| bushing | PTFE |

| "O" ring | PTFE |

| pin | stainless steel |

| key | stainless steel |

| Design Standard | EN 593 ,�†MSS SP67�†�†�†API 609�†�†BS5155 |

| Inspection &�†Test | API 598�†�†ISO 5208�†�†EN 12266 |

| End Standard | ANSI B16.1 CL. 125LB &�†B16.5 CL. 150LB

AS 2129 Table D�†& E�†�†�†BS 10 Table D�†& E DIN 2501 PN6, PN10 &�†PN16 EN 1092 PN6, PN10 &�†PN16 ISO 2531 PN6, PN10 &�†PN16 ISO 7005 PN6, PN10 &�†PN16 KS B�†1511 /�†JIS B�†2210 5K &�†10K MSS SP44 CL. 150LB�†�†AWWAC207 SABS 1123 Table 1000/3 &�†Table 1600/3 |

| Face to Face | ISO 5752 ,�†EN 558 ,�†MSS SP67 and API 609�†�†DIN3202 |

| Top Flange | ISO 5211 |

Products Detailes

Certificates

Process

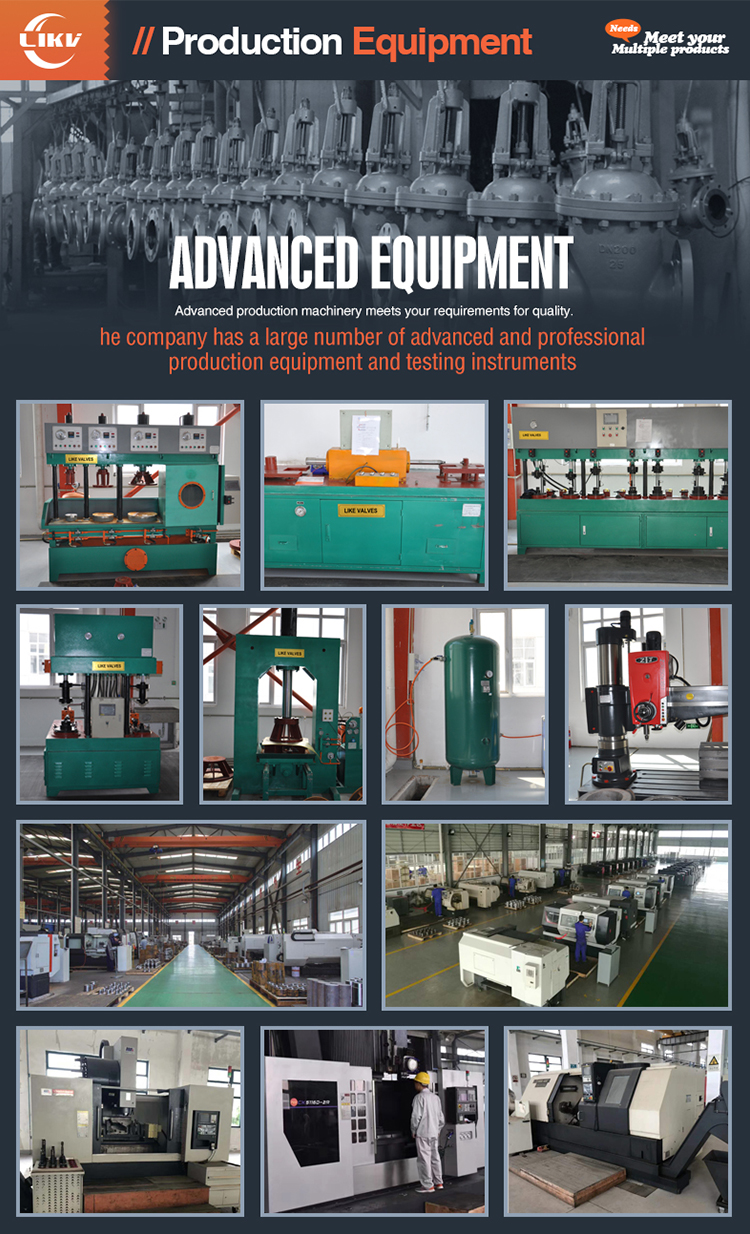

Equipments

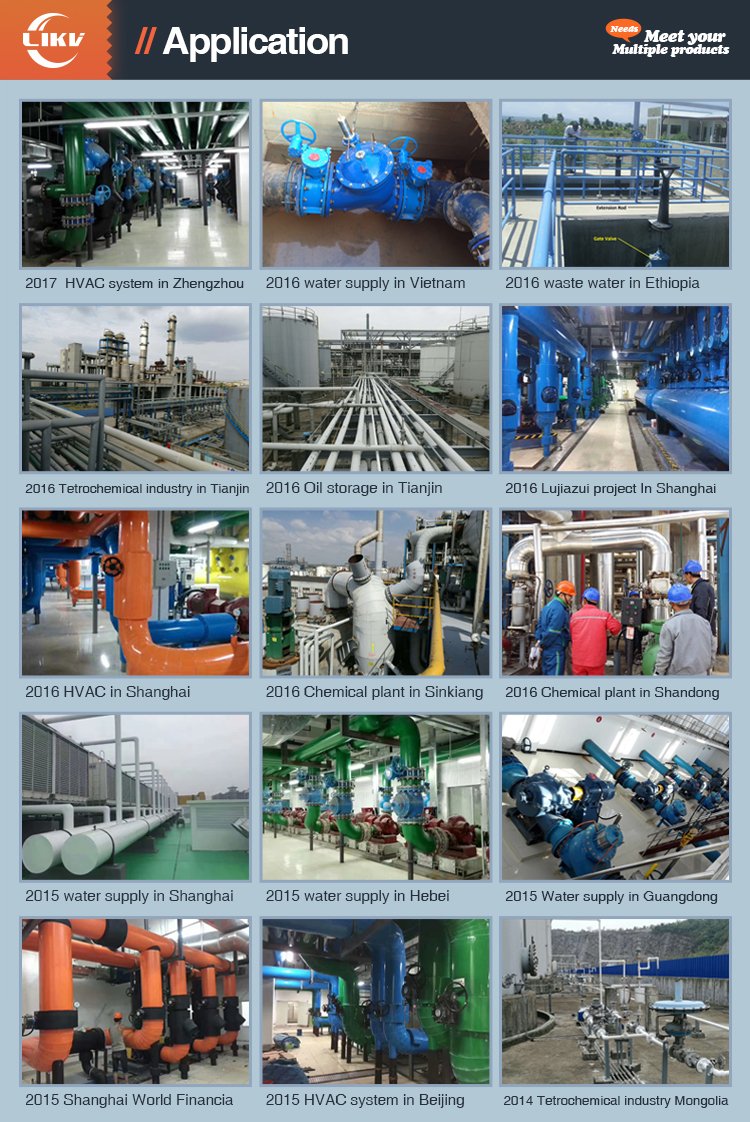

Application