We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for 100% Original China Metal Seated / Resilient Seated Lifting Check Valves, You should send us your specifications and requirements, or feel totally free to speak to us with any questions or inquiries that you may have.

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for China Check Valve, Swing Check Valve, With the growing of the company, now our products sold and served at more than 15 countries around the world,such as Europe,North America,Middle-east,South America,Southern Asia and so on. As we bear in our mind that innovation is essential to our growth, new product development is constantly.Besides, Our flexible and efficient operation strategies,High quality products and competitive prices are exactly what our customers are looking for. Also a considerable service brings us good credit reputation.

1.  The  product  has  reasonable  structure,  reliable  sealing,  excellent  performance  and  beautiful  appearance;

2.  The  sealing  surface  of  valve  disc  and  valve  seat  is  overlaid  with  Co  based  cemented  carbide,

which  has  good  wear  resistance,  corrosion  resistance,  scratch  resistance  and  long  service  life;

3.  Part  materials  and  flange  and  gasket  dimensions  can  be  reasonably  selected  according  to

actual  working  conditions  or  user  requirements  to  meet  various  engineering  needs.

Main  performance  specifications

| Design  criteria | GB/T  12235 | |||||

| Pressure  temperature  class | GB/T  12224 | |||||

| Structure  length | GB/T  12221 | |||||

| Flange  type  and  size | GB/T  9113¡¢JB/T  79¡¢EN1092¡¢ASME  B16.5/B  16.47 | |||||

| Inspection  and  test | JB/T  9092¡¢GB/T13927¡¢API598 | |||||

| Test  pressure£¨MPa£© | Nominal  pressure | PN1.6 | PN2.5 | PN4.0 | PN6.4 | PN10.0 |

| Shell  test | 2.4 | 3.8 | 6.0 | 9.6 | 15.0 | |

| High  pressure  seal | 1.8 | 2.8 | 4.4 | 7.1 | 11.0 | |

| Low  pressure  seal | 0.6 | |||||

Material  of  main  parts

| No. | Part  name | carbon  steel | stainless  steel | Alloy  steel | Low  temperature  steel |

| 1 | valve  body | WCB | CF8 | WC6 | LCB |

| 2 | Valve  disc | WCB/25 | CF8/F304 | WC6/F11 | LCB/LF2 |

| 3 | shim | Flexible  graphite | Flexible  graphite | Flexible  graphite | Flexible  graphite |

| 4 | Valve  cover | WCB | CF8 | WC6 | LCB |

| 5 | Double  end  stud | 35CrMoA | 0Cr18Ni9(304) | 25Cr2MoVA | 35CrMoVA |

| 6 | Nut | 45# | 0Cr18Ni9(304) | 35CrMoA | 45# |

| 7 | Spring | 60Si2Mn | 0Cr18Ni9(304) | 0Cr18Ni9(304) | 0Cr18Ni9(304) |

Main  overall  connection  dimensions

| DN(mm) | L | D | D1 | D2 | b-f | Z-  d | H | WT(kg) |

| 15 | 130 | 95 | 65 | 45 | 16-2 | 4-  14 | 77 | 3 |

| 20 | 150 | 105 | 75 | 58 | 18-2 | 4-  14 | 77 | 4 |

| 25 | 160 | 115 | 85 | 68 | 18-2 | 4-  14 | 80 | 5 |

| 32 | 180 | 140 | 100 | 78 | 18-2 | 4-  18 | 85 | 7 |

| 40 | 200 | 150 | 110 | 88 | 18-3 | 4-  18 | 95 | 9 |

| 50 | 230 | 165 | 125 | 102 | 18-3 | 4-  18 | 105 | 10 |

| 65 | 290 | 185 | 145 | 122 | 18-3 | 8-  18 | 120 | 20 |

| 80 | 310 | 200 | 160 | 138 | 20-3 | 8-  18 | 130 | 30 |

| 100 | 350 | 220 | 180 | 158 | 20-3 | 8-  18 | 140 | 39 |

| 125 | 400 | 250 | 210 | 188 | 22-3 | 8-  18 | 155 | 50 |

| 150 | 480 | 285 | 240 | 212 | 22-3 | 8-  22 | 180 | 70 |

| 200 | 600 | 340 | 295 | 268 | 24-3 | 12  22 | 215 | 161 |

| 250 | 730 | 405 | 355 | 320 | 26-3 | 12-  26 | 260 | 251 |

| 300 | 850 | 460 | 410 | 378 | 28-4 | 12-  26 | 315 | 395 |

Main  overall  connection  dimensions

| DN(mm) | L | D | D1 | D2 | b-f | Z-  d | H | WT(kg) |

| 15 | 130 | 95 | 65 | 45 | 16-2 | 4-  14 | 100 | 3.4 |

| 20 | 150 | 105 | 75 | 58 | 18-2 | 4-  14 | 105 | 5 |

| 25 | 160 | 115 | 85 | 68 | 18-2 | 4-  14 | 120 | 5.7 |

| 32 | 180 | 140 | 100 | 78 | 18-2 | 4-  18 | 130 | 9.1 |

| 40 | 200 | 150 | 110 | 88 | 18-3 | 4-  18 | 135 | 11.8 |

| 50 | 230 | 165 | 125 | 102 | 20-3 | 4-  18 | 149 | 14.4 |

| 65 | 290 | 185 | 145 | 122 | 22-3 | 8-  18 | 160 | 23 |

| 80 | 310 | 200 | 160 | 138 | 24-3 | 8-  18 | 169 | 30 |

| 100 | 350 | 235 | 190 | 162 | 24-3 | 8-  18 | 194 | 44 |

| 125 | 400 | 270 | 220 | 188 | 26-3 | 8-  18 | 222 | 65 |

| 150 | 480 | 300 | 250 | 218 | 28-3 | 8-  22 | 255 | 99 |

| 200 | 600 | 360 | 310 | 278 | 30-3 | 12-  22 | 305 | 190 |

| 250 | 730 | 425 | 370 | 335 | 32-3 | 12-  26 | 355 | 315 |

| 300 | 850 | 485 | 430 | 395 | 34-4 | 12-  26 | 410 | 450 |

Products Detailes

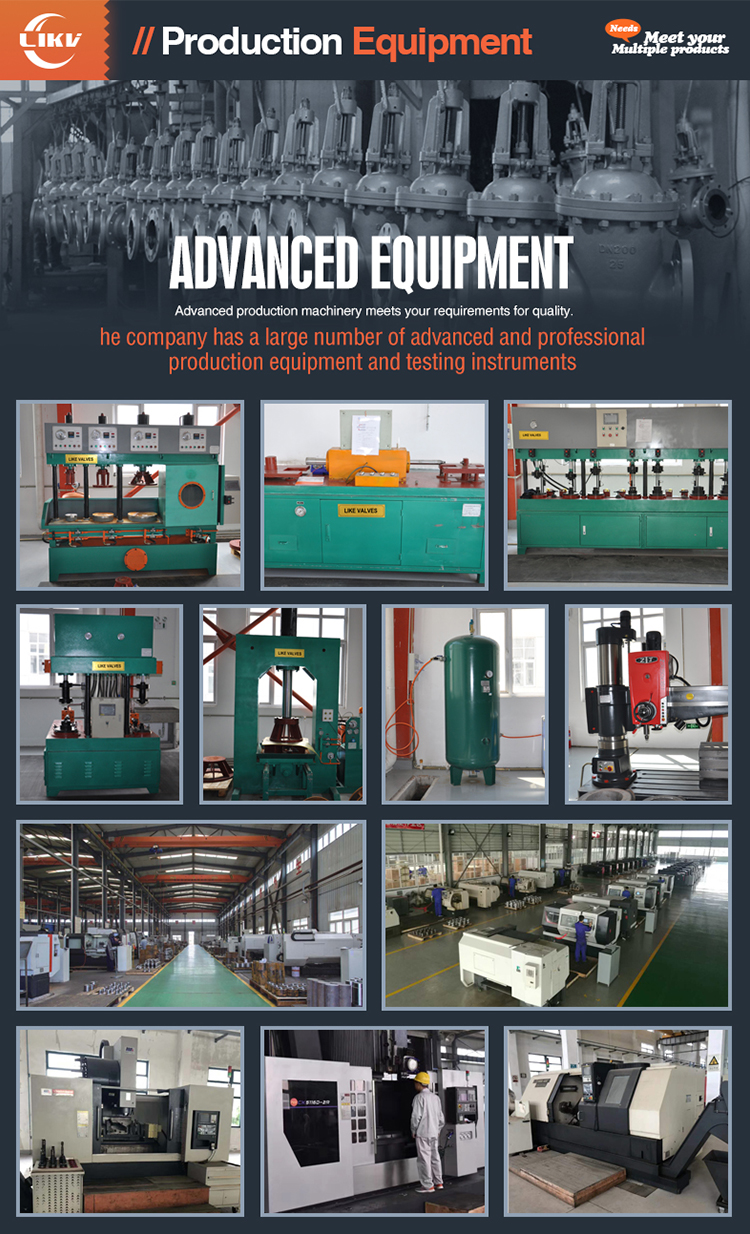

Process

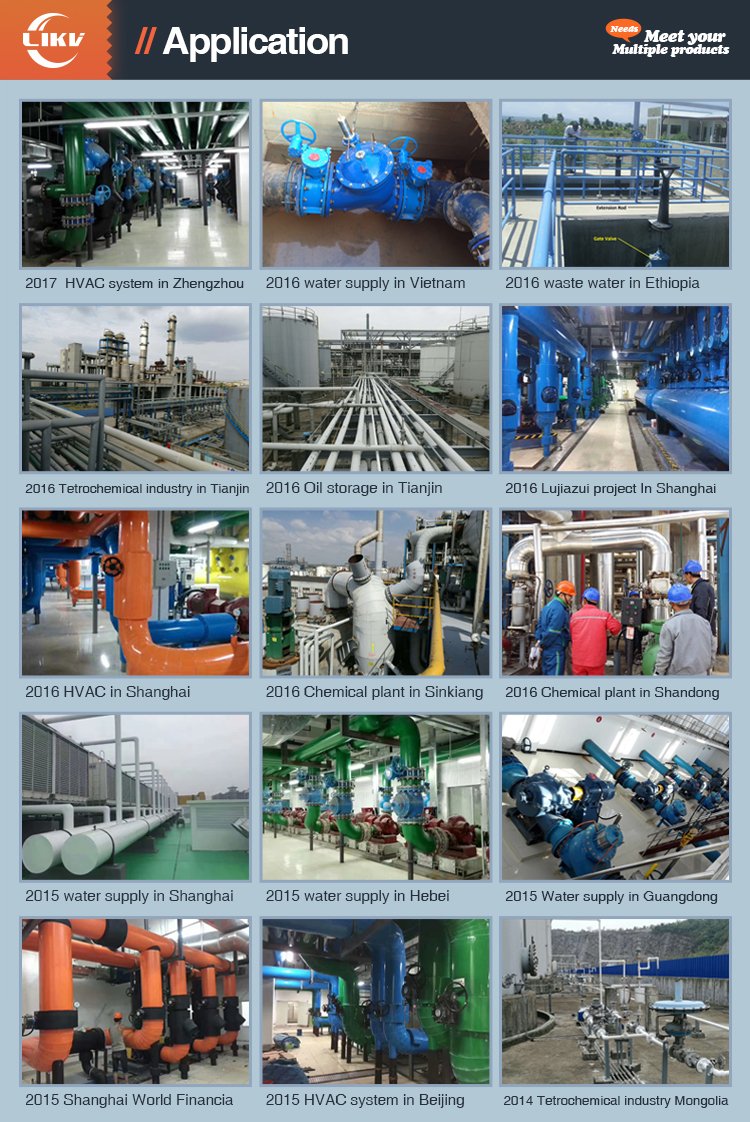

Application