Material of main parts of turbine wafer type desulfurization butterfly valve

| Part name | Material Science |

| valve body | Gray cast iron, ductile iron, carbon steel |

| Valve plate | Carbon steel coated rubber, carbon steel coated fluoroplastics, stainless steel duplex stainless steel plate 1.4529¡¢C276 |

| valve seat | Natural rubber, EPDM, rubber |

| Stem | stainless steel¡¢20Cr13¡¢304 |

| filler | Poly (vinyl chloride) |

Executive standard of turbine wafer type desulfurization butterfly valve

| Design and manufacture | API609� � GB/T12238 |

|

Flange connection |

GB/T17251.2¡¢GB/T9113¡¢EN1092¡¢ASME B16.5¡¢JIS 10K |

| Structural length | GB/T12221¡¢EN558¡¢API609 |

| Test and inspection | GB/T13927¡¢API1598 |

Main technical parameters

| Nominal diameter | DN50-DN200mm | |

| Nominal pressure | 0.6/1.0/1.6MPa | |

| Test pressure | strength | 1.5 |

| density | 1.1 | |

| seal up | 0.6 | |

| Applicable temperature | Natural rubber¡Ü85¡æ | EPDM¡Ü100¡æ |

| Applicable media | Gypsum slurry, limestone slurry, recycled water, process water, wastewater | |

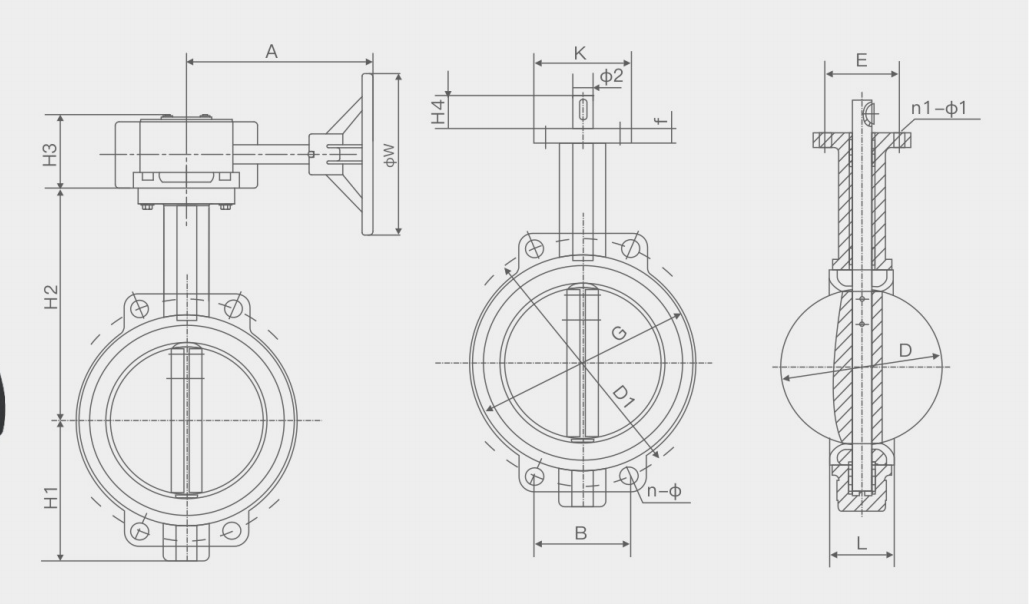

Drawing of turbine wafer type desulfurization butterfly valve

Main connecting dimensions of turbine wafer type desulfurization butterfly valve

| DN(mm£© | NPS(in) | L | D | D1 | H1 | H2 | H3 | H4 | B | N-¦µ | A | K | E | n1-¦µ1 | ¦µW | ¦µ2 | G | f |

| 50 | 2 | 43 | 52.9 | 120 | 80 | 161 | 66 | 32 | 84.84 | 4-23 | 160 | 77 | 57.15 | 4-6.7 | 150 | 12.6 | 100 | 13 |

| 65 | 2.5 | 46 | 64.5 | 136.2 | 89 | 175 | 66 | 32 | 96.2 | 4-26.5 | 160 | 77 | 57.15 | 4-6.7 | 120 | 12.6 | 120 | 13 |

| 80 | 3 | 46 | 78.8 | 160 | 95 | 181 | 66 | 32 | 61.23 | 8-18 | 160 | 77 | 57.15 | 4-6.7 | 150 | 12.6 | 127 | 13 |

| 100 | 4 | 52 | 104 | 185 | 114 | 200 | 66 | 32 | 70.8 | 4-24.5 | 160 | 92 | 69.85 | 4-10.3 | 150 | 15.77 | 156 | 13 |

| 125 | 5 | 56 | 123.3 | 215 | 127 | 213 | 66 | 32 | 82.28 | 4-23 | 160 | 92 | 69.85 | 4-10.3 | 150 | 18.92 | 190 | 13 |

| 150 | 6 | 56 | 155.6 | 238 | 139 | 226 | 66 | 32 | 91.08 | 4-25 | 160 | 92 | 69.85 | 4-10.3 | 150 | 18.92 | 212 | 13 |

| 200 | 8 | 60 | 202.5 | 295 | 175 | 260 | 82 | 45 | 112.89 | 4-25 | 240 | 115 | 88.9 | 4-14.3 | 298 | 22.1 | 268 | 13 |

| 76.35 | 4-23 | |||||||||||||||||

| 250 | 10 | 68 | 250.5 | 357 | 203 | 292 | 82 | 45 | 92.4 | 4-29 | 240 | 115 | 88.9 | 4-14.3 | 298 | 24.45 | 325 | 13 |

| 300 | 12 | 78 | 301.6 | 407 | 242 | 337 | 84 | 45 | 105.34 | 4-29 | 225 | 140 | 107.95 | 4-14.3 | 298 | 31.6 | 403 | 20 |

| 350 | 14 | 78 | 333.3 | 467 | 267 | 368 | 84 | 45 | 91.11 | 4-30 | 225 | 140 | 107.95 | 4-14.3 | 298 | 31.6 | 436 | 20 |

| 400 | 16 | 102 | 389.6 | 515 | 325 | 400 | 120 | 51.2 | 100.47 | 4-26 | 280 | 197 | 158.75 | 4-20.6 | 300 | 33.15 | 488 | 20 |

| 88 | 525 | 72 | 102.42 | 4-30 | ||||||||||||||

| 450 | 18 | 114 | 440.51 | 565 | 345 | 422 | 120 | 51.2 | 88.39 | 4-26 | 362 | 197 | 158.75 | 4-20.6 | 300 | 37.95 | 536 | 20 |

| 107 | 585 | 72 | 91.51 | 4-30 | ||||||||||||||

| 500 | 20 | 131 | 491.6 | 620 | 378 | 480 | 150 | 64.2 | 86.99 | 4-26 | 362 | 197 | 158.75 | 4-20.6 | 300 | 41.15 | 590 | 22 |

| 650 | 82 | 101.68 | 4-33 | |||||||||||||||

| 600 | 24 | 154 | 592.5 | 725 | 475 | 562 | 150 | 70.2 | 113.42 | 20-30 | 362 | 276 | 215.9 | 4-22.2 | 300 | 50.65 | 816 | 22 |

| 770 | 82 | 120.46 | 20-36 |

Product features of turbine wafer type desulfurization butterfly valve

1. The non eccentric design with medium linear structure has the characteristics of low operating torque and remarkable economy when equipped with electric device;

2. Reasonable design, compact structure, simple installation and disassembly, easy maintenance;

3. With rubber lining structure, the butterfly plate circumferential sealing surface is precision machined to a higher finish, the friction coefficient of rubber seat is low, and the valve service life is long;

4. The flow pattern of the valve plate sealing surface is linear, with small flow resistance coefficient and small valve flow resistance;

5. The designed molded rubber seat has good balance and support, which can effectively avoid the damage to rubber caused by uneven force. When the valve is fully closed, the rubber is in a good compression state to maintain zero leakage;

6. The rubber sealing surface of the two ends of the valve protrudes from the ductile iron flange surface, so there is no need for additional rubber sealing gasket when the valve is installed in the pipeline;

7. The operating mechanism of butterfly valve is flexible.