Isilawuli sikufundisa ukuthi ubhekane kalula nokuvuza kwei-valve yokulawulaendaweni yokucwenga uwoyela

Abstract: Ukukhethwa kwevalvu elawulayo kuwumsebenzi ocophelela kakhulu, hhayi nje ukuba nolwazi oluqinile lwethiyori, kodwa futhi ube nolwazi olucebile olusebenzayo.

Ukukhethwa okuhle akuzuzisi nje kuphela ukulungisa imingcele ye-PID yokusetha i-loop yokulawula, ukuze imingcele elungisiwe ithole umphumela wokulawula ongcono, kodwa futhi yenza impilo yesevisi ye-valve ikhule.

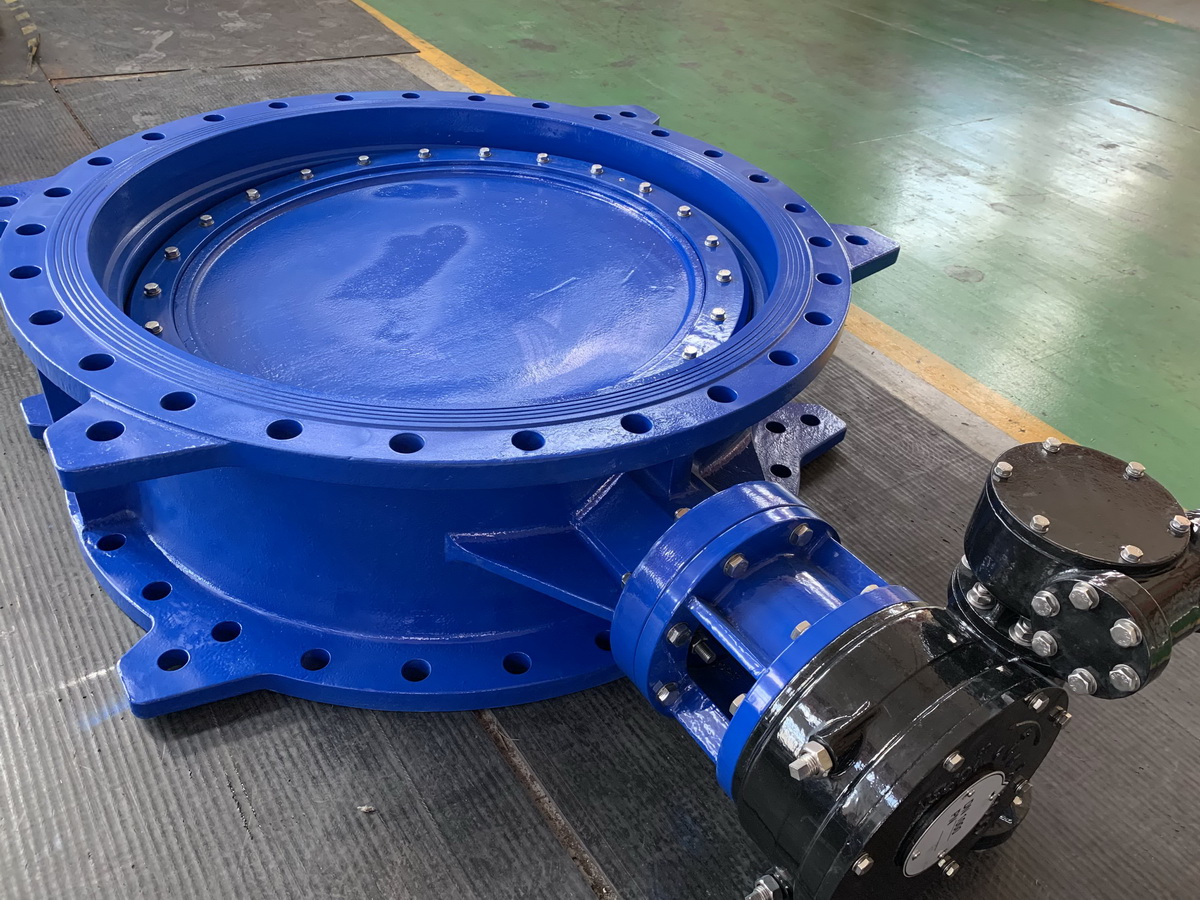

Leli phepha lethula kafushane indlela yokwakheka nokukhetha yokulawula i-valve. Amagama angukhiye: ukulawula ukwakheka kwe-valve ukukhethwa kwezigaba Ukulawula izinsimbi ozifundisa kalula ukubhekana neyunithi yokucwenga uwoyela elawula ukuvuza kwevalvu

Isingeniso: I-valve elawulayo iyingxenye ebalulekile yomshini wokucwenga we-petrochemical, ukusetshenziswa kwezinhlobonhlobo zama-valve ezilawulayo, inombolo enkulu, indawo yokukhiqiza amakhemikhali iyagqwala, inobuthi noma iyavutha futhi iyaqhuma, lapho ulawula ukuvuza kwe-valve, ngeke nje kubangele ukumosheka okukhulu kwezinto zokusetshenziswa. , amandla kanye nemikhiqizo, kodwa futhi kubangele umthelela ongathi sína emvelweni, futhi kubangele ngisho nezingozi ezimbi zokuphepha. Ngakho-ke, sikhulume ngokuvuza kwe-valve elawulayo ohlelweni lokukhiqiza i-petrochemical.

1. Ukuhlaziywa kwembangela yokuvuza kwe-valve elawulayo

Ngokuvamile, kunezindlela ezimbili zokulungisa ukuvuza kwe-valve, okuwukuthi ukuvuza kwangaphandle nokuvuza kwangaphakathi. Kokuqukethwe okulandelayo, umbhali wenza ukuhlaziywa okuningiliziwe kwezizathu zokuvuza kwangaphandle kanye nokuvuza kwangaphakathi kwe-valve elawulayo.

Ukuhlaziywa kwembangela ye-valve yokulawula engu-01 ngaphandle kokuvuza

Isizathu sokuvuza komzimba we-valve: umzimba we-valve uvame ukuphonswa, kulula ukwenza izimbobo zesihlabathi nokunye ukukhubazeka kokuphonsa, izimbobo zesihlabathi emzimbeni we-valve zizoholela ekuvuzeni kwe-medium, ukuvuza ngokuvamile kubonakala njengokuvuza, ukugeleza encane, ngokusebenzisa test hydraulic ingatholakala.

Izizathu zokuvuza kwesiqu se-valve: Ukuklama okungalungile nokukhethwa kwempahla kwesiqu se-valve kuzobangela ukuthi isiqu se-valve sibhajwe endaweni ethile, ukuze ivalvu ingakwazi ukuvaleka noma ivaleke ngokukhululeka, okuholela ekuvuzeni okuphakathi.

Isizathu sokuvuza koxhumano lomzimba we-valve: sivame ukusho ukuthi ukuvalwa kwengxenye yomzimba we-valve empeleni kubhekisela ekuxhumekeni nasekuvaleni phakathi komzimba we-valve kanye nesembozo se-valve. Imvamisa, imodi yokuvala phakathi kwe-valve nesembozo se-valve iwukuvala uphawu lokuxhuma kwe-flange; Kodwa-ke, lapho i-diameter ye-valve elawulayo incane uma kuqhathaniswa, kuyadingeka ukuthi kuthathwe indlela yokufaka uphawu yokuxhumana okunentambo. Kulezi zindlela ezimbili zokubeka uphawu, uma uhlobo lwe-gasket lungenangqondo, ikhwalithi yento engekho ezingeni, ubukhulu bezinto ezibonakalayo akuhambisani nezidingo zokubekwa uphawu, futhi izinga lokucubungula le-flange sealing surface limpofu. , ukuqina kokuxhumeka kwentambo kanye nokuqina kwe-bolt akwanele, futhi ezinye izizathu zingabangela isenzakalo sokuvuza kwamafutha negesi engxenyeni yokuxhumana yomzimba we-valve.

02 Ukuhlaziywa kwesizathu sokuvuza kwangaphakathi komnyango we-valve olawulayo

Isizathu sokuvuza kwangaphakathi kwe-valve elawulayo ukuthi i-valve elawulayo ayivalwanga ngokuqinile, okwenzeka ngokujwayelekile endaweni yokuvala yesihlalo. Izizathu eziqondile zokuvuza kwangaphakathi kwe-valve elawulayo yilezi ezilandelayo: Kunezinkinga ezithile ekwakhiweni kwesakhiwo se-valve elawulayo kanye nokukhiqizwa kwe-valve kanye nobuchwepheshe bokwakha, njengobukhulu bengxenye esakhiweni se-valve uma kukhona. iphutha elithile, futhi iphutha lidlula uhla oluvumelekile lwenqubo yokukhiqiza, okuholela ekuvalweni kwevalvu elawulayo ayiqinile, okuholela ekugelezeni okuncane kwento ephakathi endaweni yokuvuza okuqhubekayo kwedivayisi.

Ngaphezu kwamaphutha kanye nezinkinga ekuklanyeni nasekukhiqizeni i-valve, izimbangela zokuvuza kwangaphakathi komnyango we-valve olawulayo zihlanganisa nokuguqulwa kwendawo yokuvala isihlalo se-valve, uphawu lwe-valve aluqinile, okuholela ekutheni inkinga yokuvuza okumaphakathi kweyunithi yokucwenga. Inkinga yokuvuza okuphakathi okubangelwa ukuwohloka kwendawo yokuvala yesihlalo sevalvu ibonakala ngokuyinhloko njengokuvuza. Ngaphezu kwalokho, uma iyunithi yokucwenga uwoyela ilayishwe inani elincane lokungcola okuqinile phakathi nendawo, ingabangela futhi i-valve elawulayo ukuthi ivaleke ngokukhululekile, okuholela ekuvuzeni kwe-valve elawulayo, nenkinga yokuvuza okubangelwa ukungcola okuqinile. equkethwe phakathi, indlela yokuvuza nayo iwukuvuza, kodwa ukukhishwa kokugeleza kungase kube kuncane, kungase kube ukugeleza okukhulu.

Okwesibili, ukuvimbela izindlela zokuphikisa zokuvuza kwe-valve yokulawula

Lungiselela ukukhethwa komklamo we-valve

Umgomo wokulawula nokuvinjelwa kokulawula ukuvuza kwama-valve ngokuyinhloko ukuthatha uchungechunge lwezinyathelo eziphumelelayo zokunciphisa izinga lokuvuza le-valve elawulayo ngangokunokwenzeka futhi kwehlise kube phansi uma kuqhathaniswa, ukuze kunwetshwe impilo yesevisi enhle yenjongo. Ukuncishiswa kanye nokwehliswa kokuvuza okuphakathi kwevalvu elawulayo, ukwandiswa kwempilo yesevisi yendawo ephakathi nendawo eyunithi yokucwenga, ukuthuthukiswa kwezinga lokusetshenziswa kwendawo ephakathi, ngokwezinga elikhulu kuncike ekwakhiweni okuphusile nasekukhetheni ivalvu elawulayo, ikhwalithi yekhwalithi yomkhiqizo we-valve, izinga eliphakeme kakhulu lokufakwa kwama-valve nobuchwepheshe bokwakha kanye nokukhetha okulungile kwefomu lokuvalwa kwama-valve. Ngamafuphi, uma sifuna ukuxazulula nokulawula inkinga yokuvuza kwe-valve elawulayo, kufanele siqale sicabangele ukwenziwa kahle kokuklama nokukhethwa kwe-valve elawulayo.

Ukwenziwa kahle kokuhlelwa kwe-valve elawulayo nokukhetha kuhilela ukukhethwa kwefomu le-valve elawulayo, ukuklanywa kanye nokukhiqizwa kwe-valve elawulayo ngokwayo, kanye nokukhethwa kwezinto ezisetshenziswayo zamavalvu. Lapho ukhetha uhlobo lwe-valve yokulawula, kufanele ithuthukiswe kusuka ku-Angle yezidingo zezimo zenqubo kanye nokucaciswa kokuklama. Ukusetshenziswa kwe-valve elawulayo, izinga lokushisa eliphakathi nendawo, ingcindezi, izinga lokugeleza, ukwehla kwengcindezi kanye nokugqwala kwe-medium, konke kuthinta ngqo ukukhethwa kwe-valve elawulayo, kodwa futhi ngokusho kwezinga lokushisa nokugqwala kwe-medium, khetha izinto ezisetshenziswa ekulawuleni ukukhiqiza. i-valve. Ngokusho kwesipiliyoni sokwakha kanye nokusebenza kwangempela, ngaphezu kokuhlangabezana nezidingo zenqubo efanele kanye nokucaciswa kokuklama, ukukhethwa kwama-valve okulungisa kufanele futhi kucatshangelwe ngokugcwele ezimweni ezithile ezihlukahlukene, ukuze kuhambisane nezimo zokusebenza ngangokunokwenzeka, futhi ukuhlangabezana nezidingo zokusetshenziswa ngezinga elikhulu.

02 Izindlela zokuphikisa zokuvuza kwebhokisi lokupakisha

Uphawu lokupakisha oluthambile lwendabuko lufinyelelwa ngokucindezeleka kokuxhumana kwe-radial okukhiqizwa phakathi kwesiqu nokupakisha naphakathi kokupakisha nodonga oluseceleni lwebhokisi lokupakisha ngokucindezela kwe-axial kwegland yokupakisha. Ngakho-ke, amandla e-axial we-gland kumele abe mkhulu impela, okuholela ekwandeni kwe-torque yokungqubuzana phakathi kokupakisha kanye nesiqu se-valve, ukwanda kokuguga, nokuguga okusheshayo kokupakisha okuthambile. Ngakho-ke, umshudo we-gland kufanele uqiniswe njalo noma ukupakisha kufanele kushintshwe ukuze kuqinisekiswe umphumela ongcono wokuvala.

Isigxivizo esifanelekile sokupakisha kanye nenhlanganisela yokupakisha uphawu ingathuthukisa ukuthembeka kwe-valve yokulawula futhi yandise impilo yayo yesevisi. Isibonelo, inhlanganisela yokupakisha indandatho yegraphite eguquguqukayo ingcono kunaleyo yokupakisha indandatho yegraphite eguquguqukayo kuphela. Njengamanje, ukusetshenziswa kokugcwalisa indandatho ye-graphite eguquguqukayo kungaphezulu eChina. Emazweni angaphandle, ukusetshenziswa kwenhlanganisela eguquguqukayo yokupakisha indandatho ye-graphite sekudumile futhi kwazuza imiphumela emihle.

03 Susa ukuvuza kokuxhumeka komzimba we-valve

Ingxenye yokuxhumana komzimba we-valve ivalwe uphawu, ngokwesimo sayo sokubekwa uphawu i-static seal, okufanele ihlangabezane nezidingo ezilandelayo: ingakwazi ukuzivumelanisa nokushintsha okusheshayo kwezinga lokushisa nokucindezela; Ukuqaqa okuningi ngaphandle kokulimaza isici sokubeka uphawu; Isakhiwo esilula, esihlangene, ukusetshenziswa okuncane kwensimbi; Ayizweli ekudlidlizeni kanye nemithwalo yethonya; Ingakwazi ukuhlangabezana nezidingo zemidiya ehlukahlukene yokusebenza.

Ingxenye yokuxhumana yomzimba we-valve imvamisa ivalwa nge-birch groove noma i-concave ne-convex flat gasket. Eminyakeni yamuva nje, indandatho yokuvala "O" nayo isetshenzisiwe. I-Zen groove yohlobo lwe-flat gasket seal, iyi-gasket eyisicaba efakwe emgodini ovaliwe, lesi sakhiwo endaweni yokuvala, singakhiqiza ukucindezela okuphezulu kokuvala, okuvame ukudlula umkhawulo wesivuno sempahla ye-gasket, ukuze kuqinisekiswe ukuvalwa okuthembekile. Ilungele ama-valve alawula umfutho ophakathi nendawo nophezulu anengcindezi enkulu noma elingana no-4.0MPa. Ububi balesi sakhiwo sokuvala ukuthi lapho ususa i-valve elawulayo, i-gasket kunzima ukuyikhipha emgodini wokuvala. Uma isuswa ngokuqinile, i-gasket izovame ukulimala.

I-concave kanye ne-convex uhlobo lwe-flat gasket sealing, i-gasket eyisicaba efakwe endaweni ekhonkolo kanye ne-convex ye-flange yokuvalwa, uma kuqhathaniswa nesakhiwo sokuvala i-camphor groove flat gasket, inezinzuzo ezilandelayo: lapho uqaqa i-valve yokulungisa, i-gasket kulula ukuyithatha. ngaphandle; Ngoba i-groove yokuvala iwumumo wesinyathelo, ngakho-ke ukusebenza kokucubungula kungcono.

Ngokusho kwemingcele yenqubo kanye nezakhiwo eziwuketshezi, i-aluminium, ithusi, i-1Cr18Ni9Ti kanye nebhodi le-asbestos lerabha lingakhethwa njengezinto ze-gasket flat. Ipulasitiki ye-fluorine nayo iyinto evame ukusetshenziswa yokuvala i-gasket, kodwa ngenxa yokugeleza kwayo okubandayo, uma isakhiwo se-seal singakhiwe kahle, sizoholela emiphumeleni emibi.

I-"O" yokuvala indandatho, isakhiwo sayo esilula, ukukhiqiza okulula, inqobo nje uma ukwakheka kwesakhiwo se-seal kunengqondo, ngemuva kokuhlangana kungakhiqiza ukuguqulwa okwanele kwe-radial extrusion, kungafinyelelwa ngaphandle kokulayisha i-axial, ngakho-ke, ukuvala uphawu lokuxhuma kwe-flange, kunganciphisa usayizi. yesakhiwo se-flange, ngaleyo ndlela kunciphisa isisindo somthetho we-valve.

04 Izinyathelo zokuphikisa zokuvuza kwesiqu se-valve

Isiqu se-valve siyingxenye ebalulekile ye-valve, isetshenziselwa ukudlulisa, ukufeza ukushintshwa kwe-valve nokulawula. Ngenxa yokuthi isiqu se-valve ekuvuleni nasekuvaleni inqubo yokusebenza njengendima yezingxenye ezihambayo, izingxenye zokuphoqa kanye nezimpawu, ngakho-ke kufanele ibe namandla athile kanye nokuqina ukuze kuhlangatshezwane nezidingo zokuvula nokuvala i-valve, futhi isize i-valve ukuba ukudlala indima yayo yokulawula. Ngokuvamile, ukukhethwa kwezinto ze-stem kuzosebenzisa i-medium ethile ekwazi ukumelana nokugqwala, ukupakisha nezinye izinto, futhi ukusebenza kwenqubo kuba ngcono. Futhi ukuze kuqhutshekwe nokuthuthukisa ukumelana nokungqubuzana nokumelana nokugqwala kwesiqu se-valve, abasebenzi bazophinde baqinise ingaphezulu lesiqu se-valve ukuvimbela umthelela nokugqwala kwesiqu se-valve maphakathi, ukuze ukuvuza kwesiqu se-valve. ingalawulwa ngempumelelo.

isiphetho

Ukuze kuxazululwe ngokuphelele inkinga yokuvuza yevalvu elawulayo kuyunithi yokucwenga, ukulinganisa okuyinhloko uwukuthuthukisa ukukhethwa komklamo wevalvu elawulayo, bese ulawula ukuvuza kwengxenye ngayinye yevalvu elawulayo. Kungale ndlela kuphela lapho singakwazi ukuxazulula ngempumelelo nokulawula inkinga yokuvuza kwe-valve elawulayo, ukuvimbela ukuvuza kwe-medium, futhi sifinyelele inhloso yokuthuthukisa izinga lokusebenzisa le-medium.

Isikhathi sokuthumela: Dec-02-2022