0102 ib0304 ib05

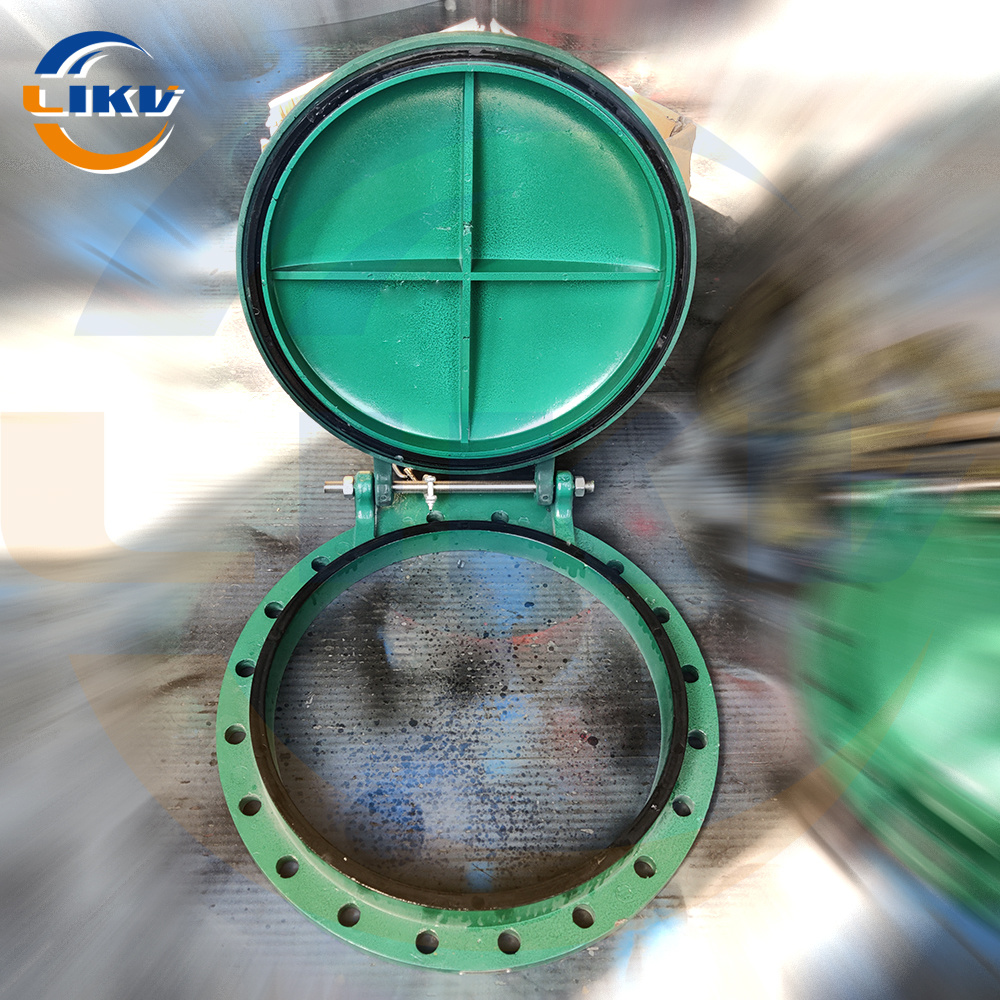

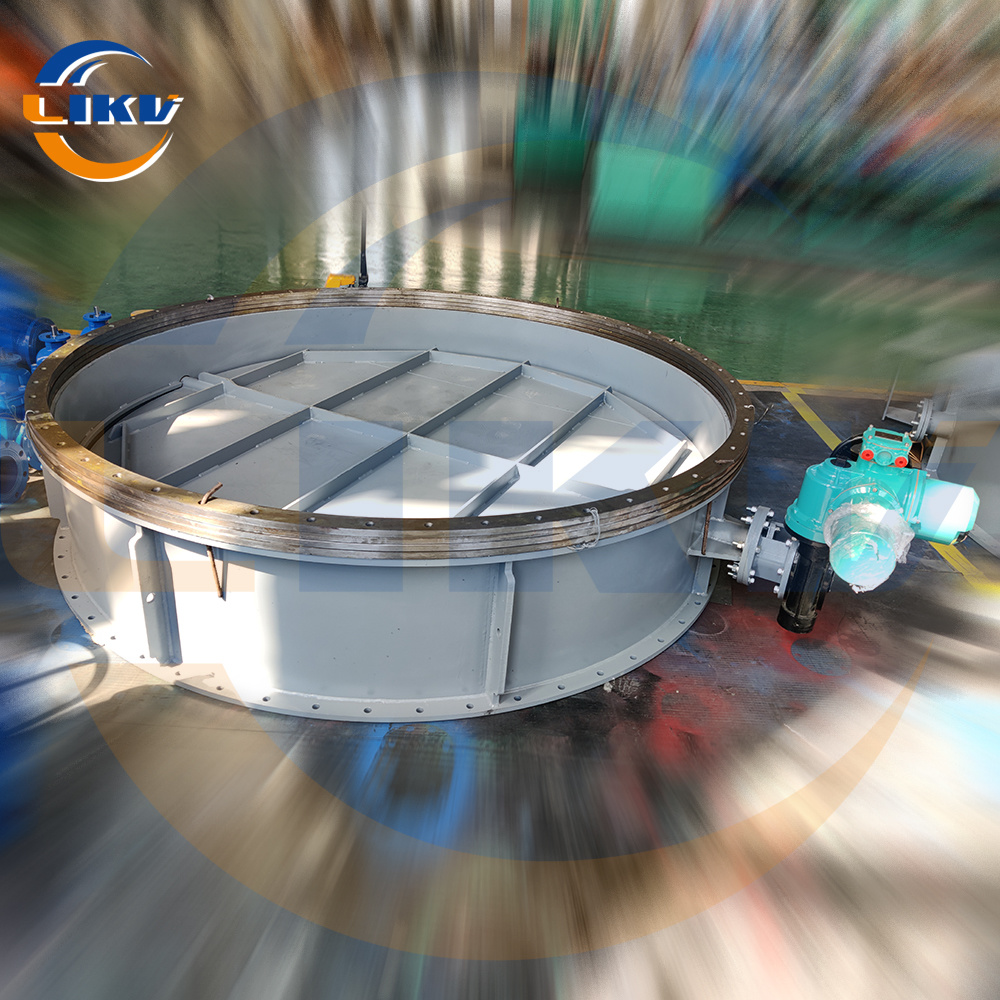

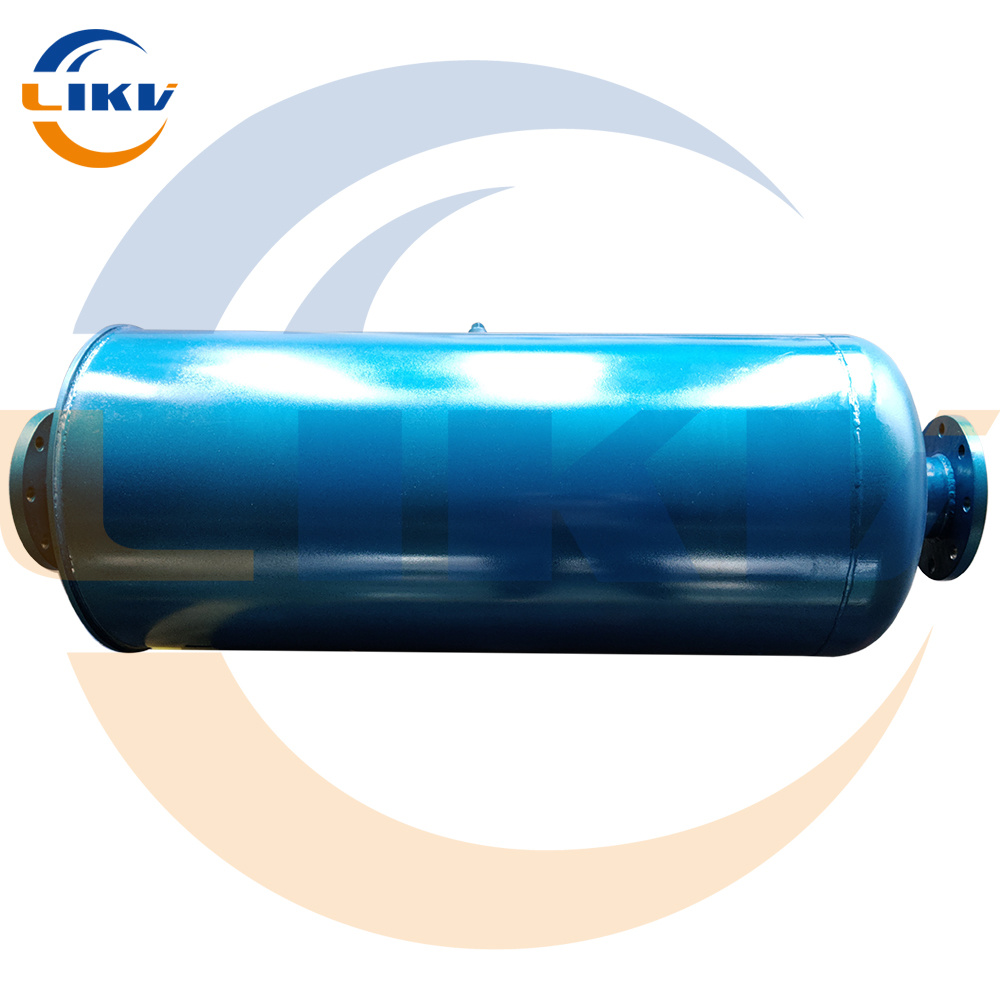

J41H / Y flange ntiaj teb valve

Cov yam ntxwv ntawm J41H / y flange globe valve 1. Cov khoom lag luam muaj cov qauv tsim nyog, kev ruaj ntseg sealing, kev ua haujlwm zoo heev thiab zoo nkauj tsos; 2. Lub sealing nto overlaid nrog Co raws li cemented carbide tau zoo hnav tsis kam, corrosion kuj, abrasion kuj thiab lub neej ntev kev pab cuam; 3. Lub qia valve muaj corrosion kuj zoo thiab khawb tsis kam tom qab quenching thiab tempering thiab nto nitriding kho; 4. Lub valve yog nruab nrog rov qab sealing qauv, uas yog txhim khu kev qha; 5. Cov khoom siv thiab flange loj tuaj yeem xaiv tau raws li kev ua haujlwm tiag tiag lossis cov neeg siv khoom kom tau raws li ntau yam kev xav tau ntawm engineering. Cov qauv kev cai tsim cov qauv tsim qauv ntev Txuas flange Test thiab tshuaj xyuas Kev kub siab GB / T 12235 GB / T 12221 JB / T 79, GB / T9113, HG / T20592, EN1092-1/2, ASME B16.5 / B16.47 JB / T 9092GB / T13927, API598 GB / Y Flange Kev Ua Haujlwm Tshwj Xeeb 2.4 3.8 6.0 9.6 15.6 Sab Nraum Xeem Ntawv 1.8 2.8 4.4 7.0 11 18 Sealing test 1.8 2.8 4.4 7.0 11 18 2. Siv nruab nrab thiab kub yam khoom siv nruab nrab Siv tau kub ℃ J41H/YC, J941H/YC Dej, roj, chav ≤425 J494W-P, acid 200 J41W-R Acetic acids ≤200 J41Y-I 、 J941Y-I Dej, roj, chav ≤550 Cov khoom siv ntawm cov khoom tseem ceeb hom Lub npe Lub cev / lub kaus mom Valve disc Sealing nto qia txiv ntseej muab lub nplhaib tuav J41H / YC / J941H / YC 25 / WCB Chromium stainless hlau 20Cr1325 H: Stainless hlau Y: cobalt raws li cemented carbide steel tooj liab alloy Flexible graphite siab zoo carbon steel malleable hlau J41W-P / J941W-P Chromium nickel steel Chromium nickel steel Chromium nickel steel chromium nickel hlau Saj zawg zog graphite stainless hlau malleable hlau J41W-R Cr Ni Mo hlau Cr Ni Mo steel Cr Ni Mo steel Cr Ni Mo steel Cr Ni Mo steel tooj liab alloy Flexible graphite stainless hlau malleable hlau J41Y-I / J941Y-I Chromium molybdenum steel Chromium molybdenum steel tooj liab alloy cobalt raws li cemented carbide steel tooj liab alloy Flexible graphite Alloy steel malleable hlau J41H / Y Kos duab ntawm lub teb chaws tus qauv flange ntiaj teb valve J41H / Y Lub teb chaws tus qauv flange nres valve PN1.6MPa lub ntsiab txuas qhov ntev DN(mm) LD D1 D2 bf Z-Φd H D0 WT( kg). 25 160 115 85 68 18 2 4- Φ14 275 160 7.4 32 180 140 100 78 18 2 4-Φ18 280 180 8.5 40 200 150 110 88 18 3 4-Φ18 515 1020 330 510 200 8 3 4-Φ18 350 240 20 65 290 185 145 122 18 3 8-Φ18 355 280 25 80 310 200 160 138 20 3 8-Φ18 400 280 35 100 350 220 180 158 20 3 8-Φ18 280 410 3 22 3 8-Φ18 460 360 75 150 480 285 240 212 22 3 8-Φ22 510 400 100 200 600 340 295 268 24 3 12-Φ22 710 400 210 250 730 405 355 320 26 4 903 320 26 320 400 400 460 410 378 28 4 12-Φ26 925 500 648 J41H/Y Lub teb chaws tus qauv flange hom nres valve PN2.5MPa lub ntsiab txuas qhov ntev DN (mm) LD D1 D2 bf Z-Φd H D0 WT (kg) 10 130 90 60 40 16 2 4-Φ14 198 120 4.9 15 160 45 95 -Φ14 218 120 5.4 20 150 105 75 58 18 2 4-Φ14 258 140 7 25 160 115 85 68 18 2 4-Φ14 275 160 401 7. Φ18 280 180 8.5 40 200 150 110 88 18 3 4-Φ18 330 200 12.5 50 230 165 125 102 20 3 4-Φ18 350 240 16 65 290 185 145 122 22 3 8-Φ18 2018 38 24 3 8-Φ18 355 280 30 100 350 235 190 162 24 3 8-Φ22 415 320 34.5 125 400 270 220 188 26 3 8-Φ26 460 360 89 150 480 300 250 218 280 60 300 250 218 280 300 360 310 278 30 3 12-Φ26 710 400 180 250 730 425 370 335 32 3 12-Φ30 789 450 446 300 850 485 430 395 34 4 16-Φ30 925 500 654 J41H/Y Main Dimension of flange Flange DN2mm DN20MP valve Φd H D 0 WT(kg) 10 130 90 60 40 16 2 4 4-Φ14 198 120 4.9 15 13 95 65 45 16 2 4 4-Φ14 238 120 5.4 20 475 20 140 7 25 160 115 85 ib 68 18 2 4 4-Φ14 285 160 8.8 32 180 140 100 78 18 2 4 4-Φ18 302 180 11.8 40 200 150 110 885 140 3 230 165 125 102 20 3 4 4-Φ18 370 240 24 65 290 185 145 122 22 3 4 8-Φ18 408 280 33 80 310 200 160 138 24 3 4 8-Φ18 436 320 4510 320 320 4501 5 8-Φ22 480 360 60 125 400 270 220 188 26 3 4.5 8-Φ26 558 400 89 150 480 300 250 218 28 3 4.5 8-Φ26 611 400 98 200 600 375 320 285 35410 3