0102030405

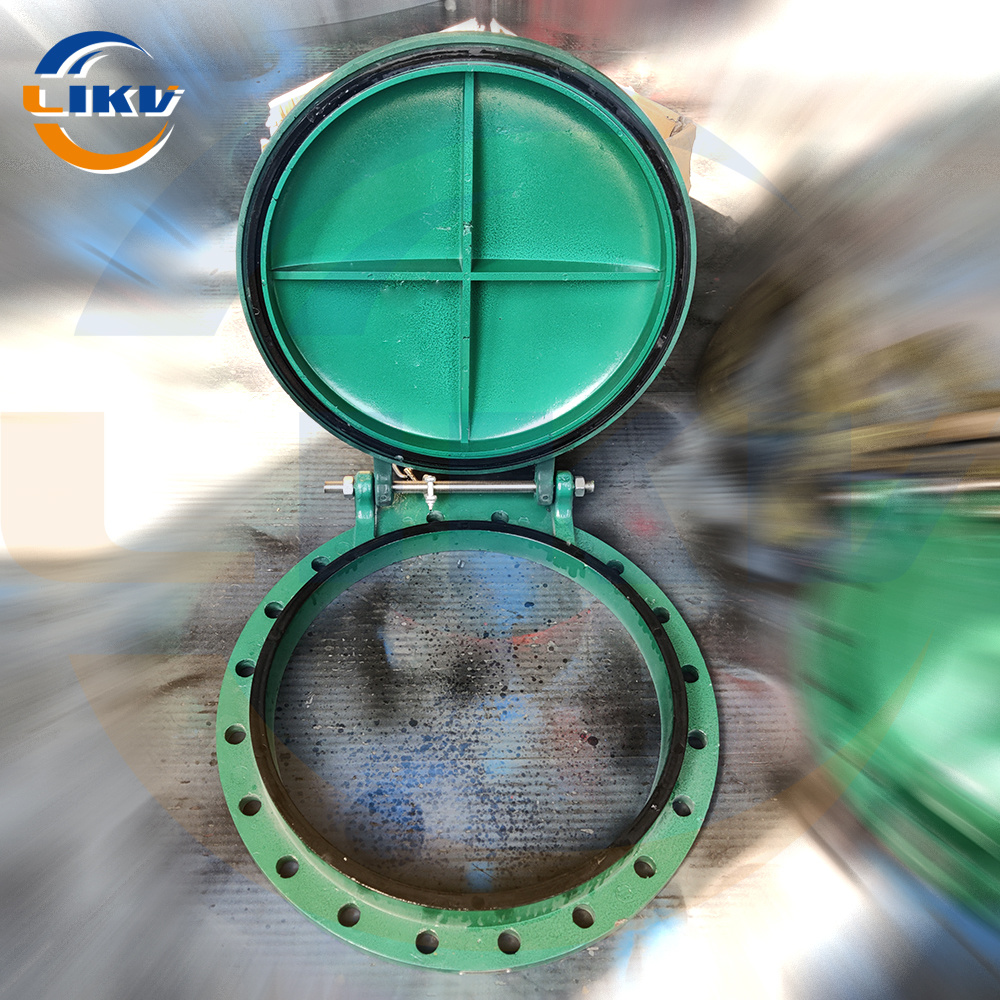

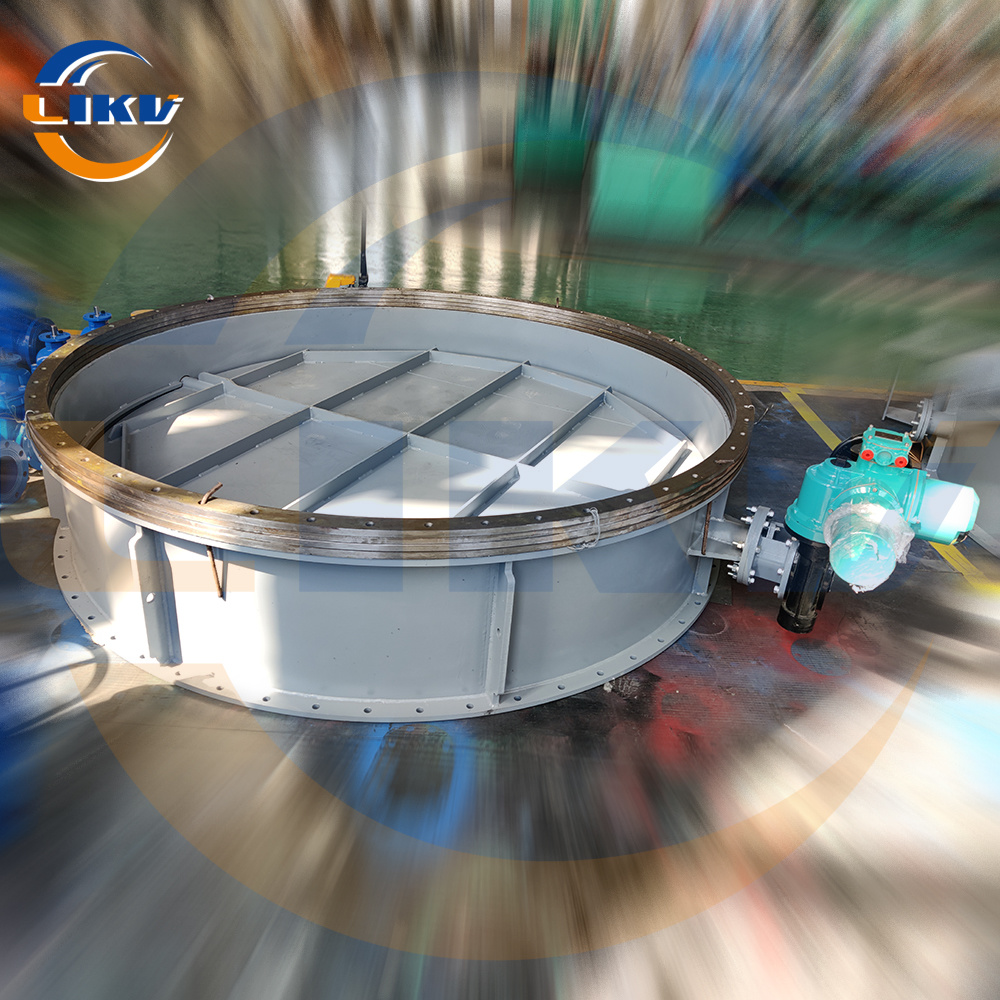

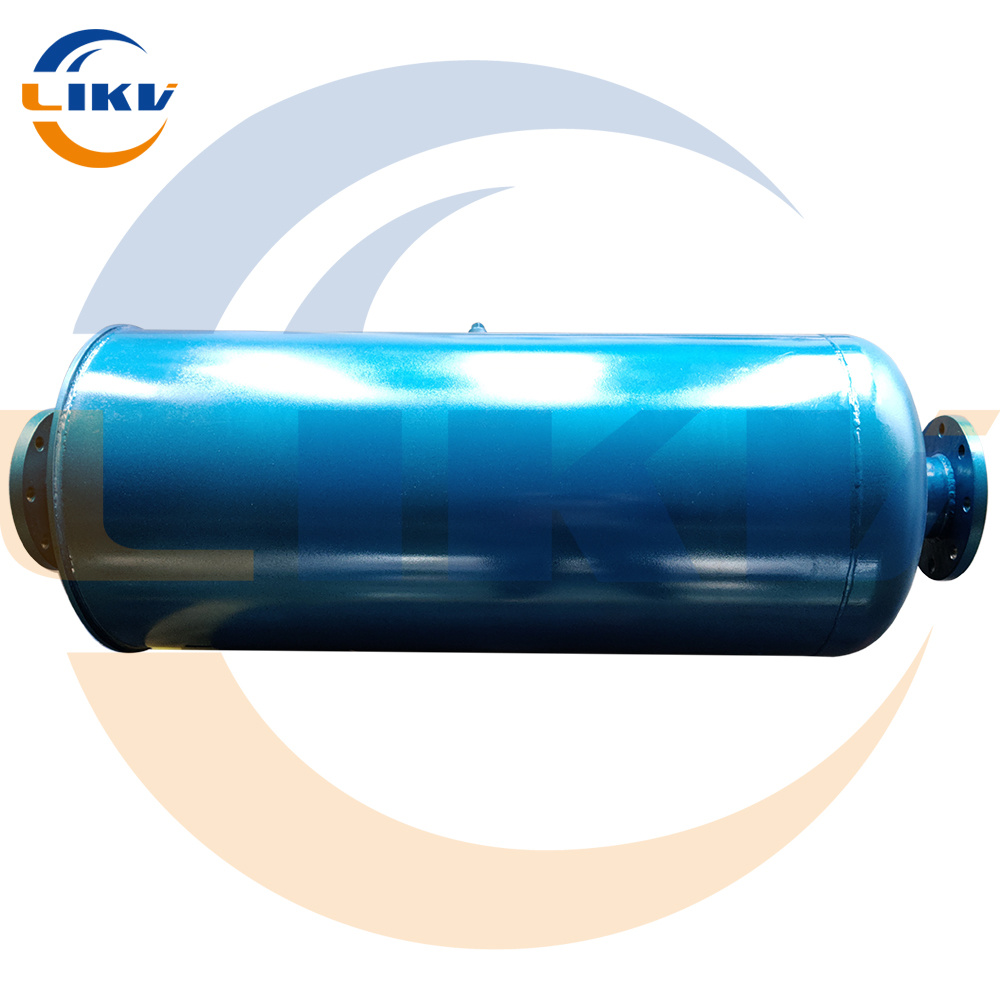

Ụlọ ọrụ mmepụta ihe maka DN50 2" Ductile Iron Cast Iron igwe anaghị agba nchara Flange Wafer Center Butterfly Valve

Anyị na-enweta ọrụ ahụ mgbe niile ịbụ onye ọrụ na-ahụ anya na-eme ka ijide n'aka na anyị nwere ike ịnye gị ezigbo mma yana ọnụ ahịa ire ere maka ụlọ ọrụ mmepụta ihe maka DN50 2" Ductile Iron Cast Iron Stainless Steel Flange Wafer Center Butterfly Valve, Anyị na-ejidekarị na nkà ihe ọmụma nke imeri-emeri, na-ewu ogologo oge imekọ ihe ọnụ mmekọrịta na ahịa si n'ụwa nile.We kwere na anyị ibu isi na ndị ahịa rụzuru, kredit akụkọ ihe mere eme bụ anyị ndụ anyị na-mgbe ọrụ mere ịbụ a tangible workforce na-eme ka n'aka na Anyị nwere ike ịnye gị ihe kachasị mma yana ọnụahịa ire ere maka China Wafer Butterfly Valve na Butterfly Valve, Anyị ga-eme ike anyị niile iji kwado & afọ ojuju na ị dabere na ogo ọkwa dị elu na ọnụahịa asọmpi na kacha mma mgbe ọrụ gasịrị. , ji obi eziokwu na-atụ anya na-arụkọ ọrụ na gị na-eme ka rụzuru n'ọdịnihu ihe onwunwe nke isi akụkụ nke turbine wafer ụdị desulfurization urukurubụba valvụ Nkebi aha Ihe Science valvụ ahụ Grey nkedo ígwè, ductile ígwè, carbon ígwè Valve efere Carbon ígwè ntekwasa roba, carbon steel ntekwasa fluoroplastics, igwe anaghị agba nchara duplex igwe anaghị agba nchara efere 1.4529, C276 valvụ oche Natural roba, EPDM, roba Stem igwe anaghị agba nchara, 20Cr13, 304 filler Poly (vinyl chloride) Executive ọkọlọtọ nke turbine wafer ụdị desulfurization Flat nru ububa chepụta na imepụta API12293 GB8 njikọ GB/T17251.2,GB/T9113,EN1092,ASME B16.5,JIS 10K Structural ogologo GB/T12221, EN558,API609 Ule na nnyocha GB/T13927,NAPIN150min-minal parameters .6/1.0 / 1.6MPa Ule mgbali ike 1.5 njupụta 1.1 akara elu 0.6 Ọdabara okpomọkụ Natural roba≤85℃ EPDM≤100℃ Ọdabara media Gypsum slurry, limestone slurry, recycled mmiri, nhazi mmiri, mmiri mkpofu Drawing nke turbine wafer ụdị valvụ na-ejikọta ọnụ desulfur. turbine wafer ụdị desulfurization urukurubụba valvụ DN(mm) NPS(na) LD D1 H1 H2 H3 H4 B N-Φ AKE n1-Φ1 ΦW Φ2 G f 50 2 43 52.9 120 80 161 66 32 84.5 14.74 120 84.74 120 84.7 32 84.7 12 84.84. 6.7 150 12.6 100 13 65 2.5 46 64.5 136.2 89 175 66 32 96.2 4-26.5 160 77 57.15 4-6.7 120 12 130 120 12 81 66 32 61.23 8-18 160 77 57.15 4-6.7 150 12.6 127 13 100 4 52 104 185 114 200 66 32 70.8 4-24.5 160 92 69.85 4-10.3 150 15.77 156 13 125 5 52 123 123 8 . 4-23 160 92 69.85 4-10.3 150 18.92 190 13 150 6 56 155.6 238 139 226 66 32 91.08 4-25 160 92 69.85 4-10.3 150 18.92 212 13 200 8 60 202.5 295 17126 171240 15 88.9 4-14.3 298 22.1 268 13 76.35 4-23 250 10 68 250.5 357 203 292 82 45 92.4 4-29 240 115 88.9 4-14.3 298 24.45 325 13 300 12 78 301.6 407 24845 3 40 107.95 4-14.3 298 31.6 403 20 350 14 78 333.3 467 267 368 84 45 91.11 4-30 225 140 107.95 4-14.3 298 31.6 436 20 400 16 102 389.6 515 325 400 120 51.427-140. 20.6 300 33.15 488 20 88 525 72 102.42 4-30 450 18 114 440.51 565 345 422 120 51.2 88.39 4-26 362 197 158.75 4-20.6 300 37.95 536 20 107 585 72 91.51 4-30 510 8 8 150 64.2 86.99 4-26 362 197 158.75 4-20.6 300 41.15 590 22 650 82 101.68 4-33 600 24 154 592.5 725 475 562 150 70.2 113.42 20-30 362 276 215.9 4-22.2 300 50.621 6 Product atụmatụ nke turbine wafer ụdị desulfurization urukurubụba valvụ 1. The non eccentric imewe na Ọdịdị linear ọkara nwere njirimara nke torque arụ ọrụ dị ala na akụnụba dị ịrịba ama mgbe ejiri ngwaọrụ eletrik rụọ ọrụ; 2. Nhazi ezi uche dị na ya, nhazi kọmpat, ntinye dị mfe na nkwụsịtụ, nhazi dị mfe; 3. Na roba lining Ọdịdị, na urukurubụba efere circumferential sealing elu bụ nkenke machined ka a elu imecha, esemokwu ọnụọgụ nke oche roba dị ala, na valvụ ọrụ ndụ dị ogologo; 4. Usoro nrịba nke valvụ plate sealing elu bụ linear, nke nwere obere nguzogide nguzogide na obere nguzogide valvụ; 5. The e mere kpụrụ rọba oche nwere ezi nguzozi na nkwado, nke nwere ike n'ụzọ dị irè zere mmebi nke roba kpatara na-enweghị isi ike. Mgbe valvụ ahụ mechiri nke ọma, rọba nọ n'ọnọdụ mkpakọ dị mma iji nọgide na-agbapụta efu; 6. Ihe mkpuchi mkpuchi roba nke akụkụ abụọ nke valvụ ahụ na-apụta site na ductile iron flange surface, n'ihi ya, ọ dịghị mkpa maka mkpuchi mkpuchi roba ọzọ mgbe a na-etinye valve na pipeline; 7. Usoro ọrụ nke valvụ urukurubụba na-agbanwe.