0102030405

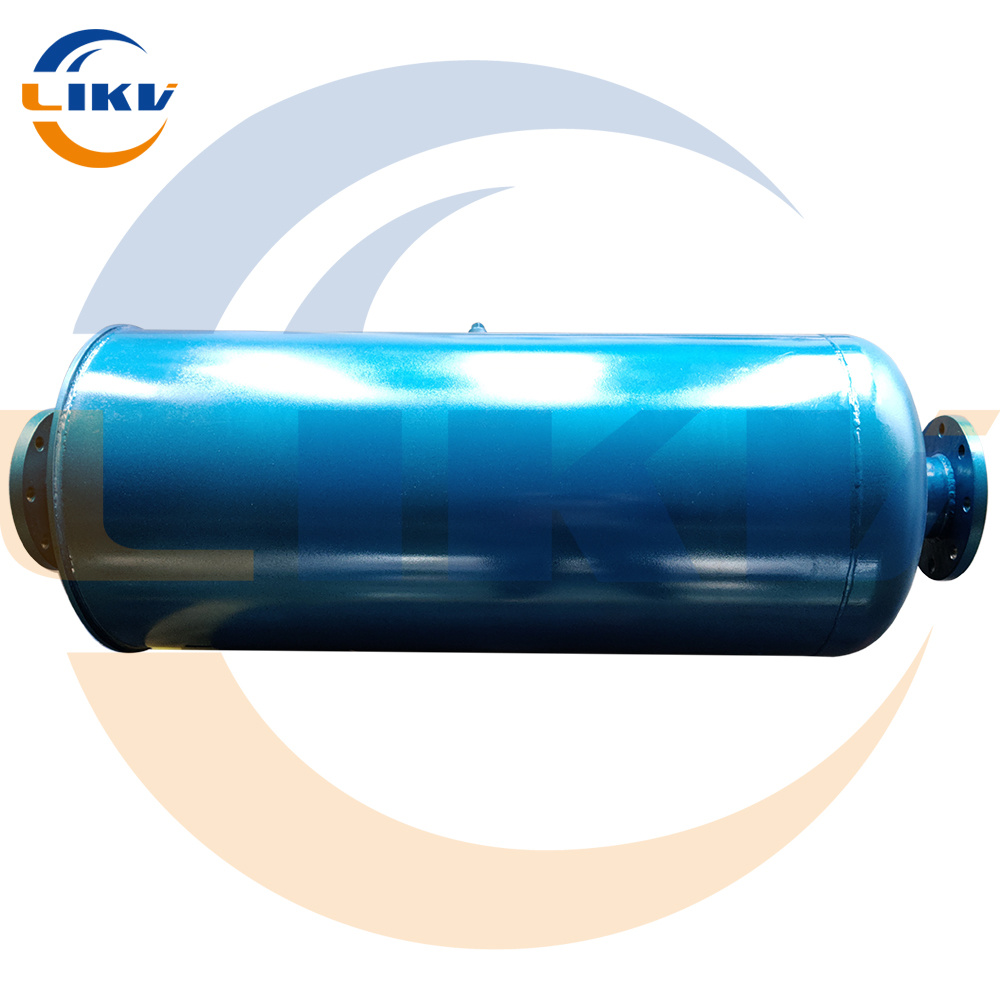

Mmiri micro enyemaka valvụ

Ihe nke isi akụkụ NO. Akụkụ aha udidi nke ihe 1 flange A42Y-160,KA42Y-230 A42Y-160/320P A42Y-160/320R 2 Valve oche 35/35CrMoA 20Cr13 1Cr18Ni1 2Mo2Ti 3 valve body140 Ni valvụ 20Cr13 1Cr18Ni9Ti 1Cr18Ni1 2Mo2Ti 5 Valve diski. 20Cr13 1Cr18Ni9Ti 1Cr18Ni1 2Mo2Ti 6 Recoil plate 20Cr13 1Cr18Ni9Ti 1Cr18Ni1 2Mo2Ti 7 Nduzi aka uwe 20Cr13 1Cr18Ni9Ti 1Cr18G25G04Mo ZG230-450 9 azuokokoosisi 20Cr13 1Cr18Ni9Ti 1Cr18Ni9Ti 10 Mmiri 50CrVA 50CrVACoated fluoroplastics 50CrVACoated fluoroplastics 11 Screw mmezi 45 20Cr13 20Crve13 12 okpu ZG200-400 ZG200-400 ZG200-400 Sealing elu material Surfacing Co dabeere cemented carbide Main njikọ akụkụ nlereanya Nominal dayameta d0 DMKD Z-Φd b d1 M1 K1 D1 Z-Φd B1 L L1 ≈H A42Y-14 × 05 M 2 60 98 3-18 20 29 M42×2 80 115 4-18 22 95 100 220 20 8 27 M33×2 68 105 3-18 20 29 M42×2 80 112 4-18 3× 2 68 105 3-18 20 50 M64×3 115 165 6-26 32 150 150 280 32 15 37 M42×2 80 115 4-18 22 50 M64×3 125-26 5 0 0 47 M52 × 2 115 165 6-26 28 65 M80×3 145 200 6-29 40 180 180 495 50 25 59 M64×2 115 165 6-26 32 80 M100×23 5 0 170 2Y-320 15 8 27 M33×2 68 105 3-18 20 29 M42×2 80 115 4-18 22 95 100 220 20 8 30 M33×2 75 110 3-18 22 29 M42×2 2 5 0 1 14 35 M42×2 80 115 4-18 22 50 M64×3 115 165 6-26 32 150 150 280 32 15 41 M48×2 95 135 4-22 25 50 M164 15 3 1 0 40 50 58 M64×2 115 165 6-26 32 65 M80×3 145 200 6-29 40 180 180 495 50 25 70 M80×2 145 200 6-29 40 200 M170 170 400 A42Y- 400 32 15 41 M48×2 95 135 4-22 25 50 M64×3 115 165 4-26 32 150 150 397