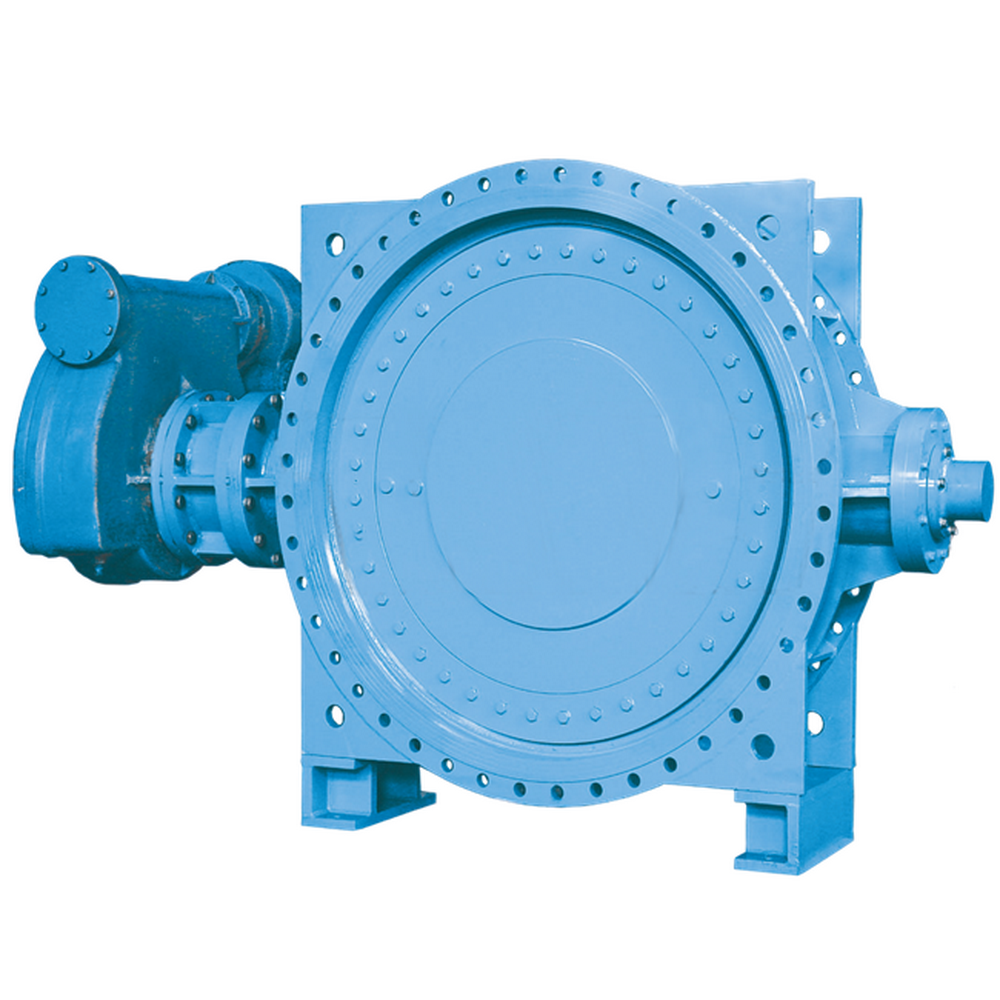

With the continuous development of industrial automation and the rapid rise of intelligence, the hydraulic butterfly valve, as an important control element, plays a vital role in industrial production. LIKV valves, as a leading valve manufacturer in China, has made remarkable achievements in the development and application of hydraulic butterfly valves. This article will introduce the innovation and development of LIKV valves in the field of hydraulic butterfly valves, and look forward to the future trend of hydraulic butterfly valves.

First, LIKV valve in the field of hydraulic butterfly valve innovation and development

1. Technological innovation

LIKV valve has been committed to technological innovation, and constantly improve product quality and performance. In the design and manufacture of hydraulic butterfly valves, LIKV valves introduce advanced materials and processes, such as high-performance polymers, cemented carbide, etc., so that the valve’s sealing, wear resistance and corrosion resistance have been greatly improved. In addition, LIKV valves also use advanced numerical simulation and simulation technology to optimize the fluid dynamics characteristics of the valve, improving the control accuracy and response speed of the valve.

2. Intelligent application

LIKV valves combine intelligent technology with hydraulic butterfly valves to realize intelligent control and monitoring of valves. By adding sensors and actuators to the valve, LIKV valves can achieve remote monitoring and control, real-time monitoring and adjustment of valve status, working parameters, etc. At the same time, LIKV valves has also developed an intelligent valve control system that can be seamlessly integrated with the factory’s automation control system, improving production efficiency and safety.

3. Be environmentally friendly

LIKV valves focus on the environmentally friendly performance of products, and adopt energy saving and environmental protection technologies in the design and manufacture of hydraulic butterfly valves. For example, LIKV Valves has developed a low resistance and high efficiency valve seat design that reduces the valve’s energy consumption. At the same time, LIKV valves also use renewable materials and environmentally friendly coatings to reduce the negative impact on the environment, and through optimized design, reduce leakage and leakage of valves, improving the efficiency and stability of the process.

Second, the future trend of hydraulic butterfly valve

1. Multi-functional

With the in-depth development of industrial automation, hydraulic butterfly valves not only need to have basic adjustment and cut-off functions, but also need to have more multi-functional characteristics. For example, with flow measurement, pressure regulation, temperature control and other functions, to achieve integrated control and monitoring. LIKV valves will continue to explore and develop new functions and apply them to the hydraulic butterfly valve to make the valve more intelligent and multi-functional.

2. High performance

The hydraulic butterfly valve undertakes important control tasks in industrial production, and the requirements for performance are getting higher and higher. In the future, LIKV valves will continue to strive to improve the performance of hydraulic butterfly valves to meet the needs of valves in various industries. In terms of high performance, LIKV valves will focus on improving the accuracy, stability and reliability of valves. Through the introduction of advanced sensor technology and control algorithm, the precise control and highly stable working state of the valve are achieved. This will help improve the automation of the production process and production efficiency, while reducing human error and instability factors.

3. Networking and connectivity

With the rise of the industrial Internet, the networking and interconnection functions of the hydraulic butterfly valve will become a trend. LIKV Valves will be committed to developing hydraulically controlled butterfly valve products that support industrial Internet protocols to achieve information exchange and data sharing between valves and systems. This will lead to more efficient production and maintenance management, such as real-time monitoring of valve status, remote diagnosis and regulation. At the same time, through the interconnection with other equipment and systems, such as sensors, meters, control systems, etc., to achieve automated and intelligent integrated management.

4. Safety and reliability

Safety is a crucial consideration in industrial production. LIKV Valves will continue to focus on the safety and reliability of hydraulically controlled butterfly valves. Through the introduction of advanced valve design and manufacturing technology, strengthen the sealing and pressure resistance of the valve to ensure the safe operation of the valve in the harsh environment such as high temperature, high pressure and corrosion. At the same time, LIKV valves will also strengthen the valve fault diagnosis and monitoring function to detect and solve potential fault problems in advance to ensure the safety and reliability of the production process.

In summary, LIKV Valves, as a leading valve manufacturer, will promote the development of hydraulic butterfly valves through technological innovation, intelligent applications and environmentally friendly performance. In the future, the hydraulic butterfly valve will show the trend of multi-function, high performance, networking and safety and reliability. LIKV valves will continue to be committed to meeting market demand and contributing to the development of industrial automation.

Post time: Jul-06-2023