In industrial fluid systems, the optimization of LIKV valves is essential for the stable operation of the system. This paper will deeply study the role and influence of the hydraulic butterfly valve, discuss its key role in flow regulation, pressure control and energy consumption optimization, and introduce the design principle and application cases of the hydraulic butterfly valve.

1, the working principle of hydraulic butterfly valve

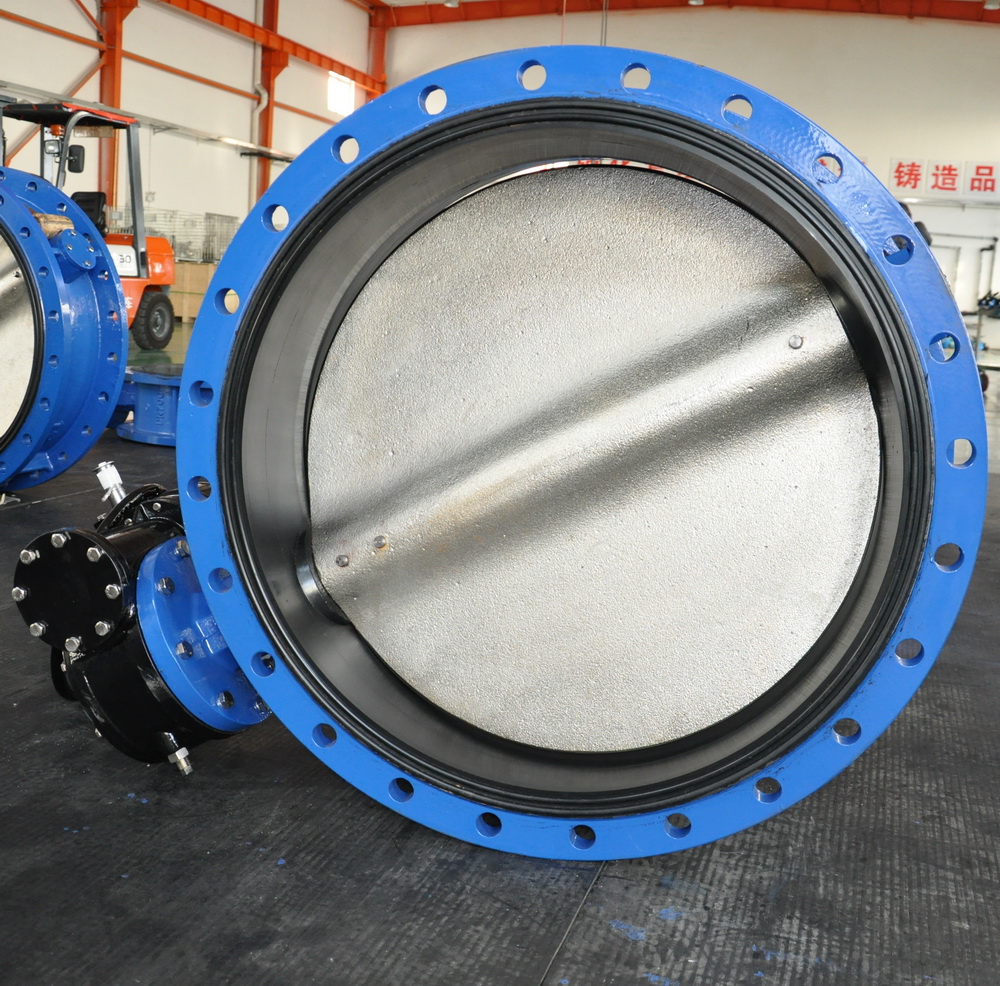

The hydraulic butterfly valve is a valve powered by liquid pressure, which regulates the flow rate and pressure of the fluid by controlling the opening and closing degree of the valve disc. It is mainly composed of a valve body, a valve disc and a driving device. When hydraulic pressure is applied to the drive device, the drive device pushes the disc to rotate, thus changing the size of the opening through which the fluid passes through the body. The design of the hydraulic butterfly valve makes it have a large flow regulation capacity and a small resistance loss in the regulation range, which makes it widely used in industrial fluid systems.

2, the role and influence of hydraulic butterfly valve

Hydraulically controlled butterfly valves play multiple roles and have an important impact on industrial fluid systems. First of all, it can achieve accurate flow regulation, so as to meet the flow requirements under different working conditions. By controlling the opening of the disc, the hydraulically controlled butterfly valve can reduce or increase the flow of fluid, enabling it to optimize fluid distribution and control in the system.

Secondly, the hydraulic butterfly valve is also of great significance for the control of pressure. By adjusting the opening and closing degree of the valve disc, the hydraulic butterfly valve can adjust the pressure of the fluid in the system to ensure the operation of the system within the set safety range. This is critical in many industrial fluid systems, especially where precise control of fluid pressure is required.

In addition, the energy consumption optimization of the hydraulic butterfly valve is also one of its important influences. Due to the design and structural characteristics of the valve disc, the hydraulic butterfly valve can reduce the resistance loss when the fluid passes through the valve body in actual operation, reduce energy consumption and operating costs.

3. Application case of hydraulic butterfly valve

Application cases of hydraulic butterfly valves are widely found in industrial fluid systems in various fields. Taking the petrochemical, water treatment and power generation fields as an example, hydraulic butterfly valves are widely used in pipeline flow regulation, pressure control and energy consumption optimization.

In the petrochemical field, hydraulic butterfly valves are often used for fluid control and pressure regulation in oil refining processes. By monitoring flow and pressure in real time and adjusting to the needs of the system, precise fluid control and efficient refining operations can be achieved.

In the field of water treatment, hydraulic butterfly valves are often used in water supply, sewage treatment and industrial wastewater treatment systems. By adjusting the opening of the valve flap, water flow regulation and pressure control can be achieved to maintain the system

Post time: Jun-30-2023