Maintenance of Chinese Double Half Axis Non Pin Butterfly Valve: Revealing Its Working Principle and Efficient Maintenance Strategy

Introduction:

In today’s era, China’s double half shaft non pin butterfly valve has become an indispensable component in the industrial field. It provides reliable support for various fluid control systems with its unique structural design and excellent performance. However, many enterprises often overlook the importance of maintenance and upkeep when using Chinese double half shaft unsellable butterfly valves. This article will provide an in-depth analysis of the working principle of Chinese double half shaft non pin butterfly valves and provide you with an efficient and practical maintenance strategy.

1¡¢ Working principle of Chinese double half shaft non pin butterfly valve

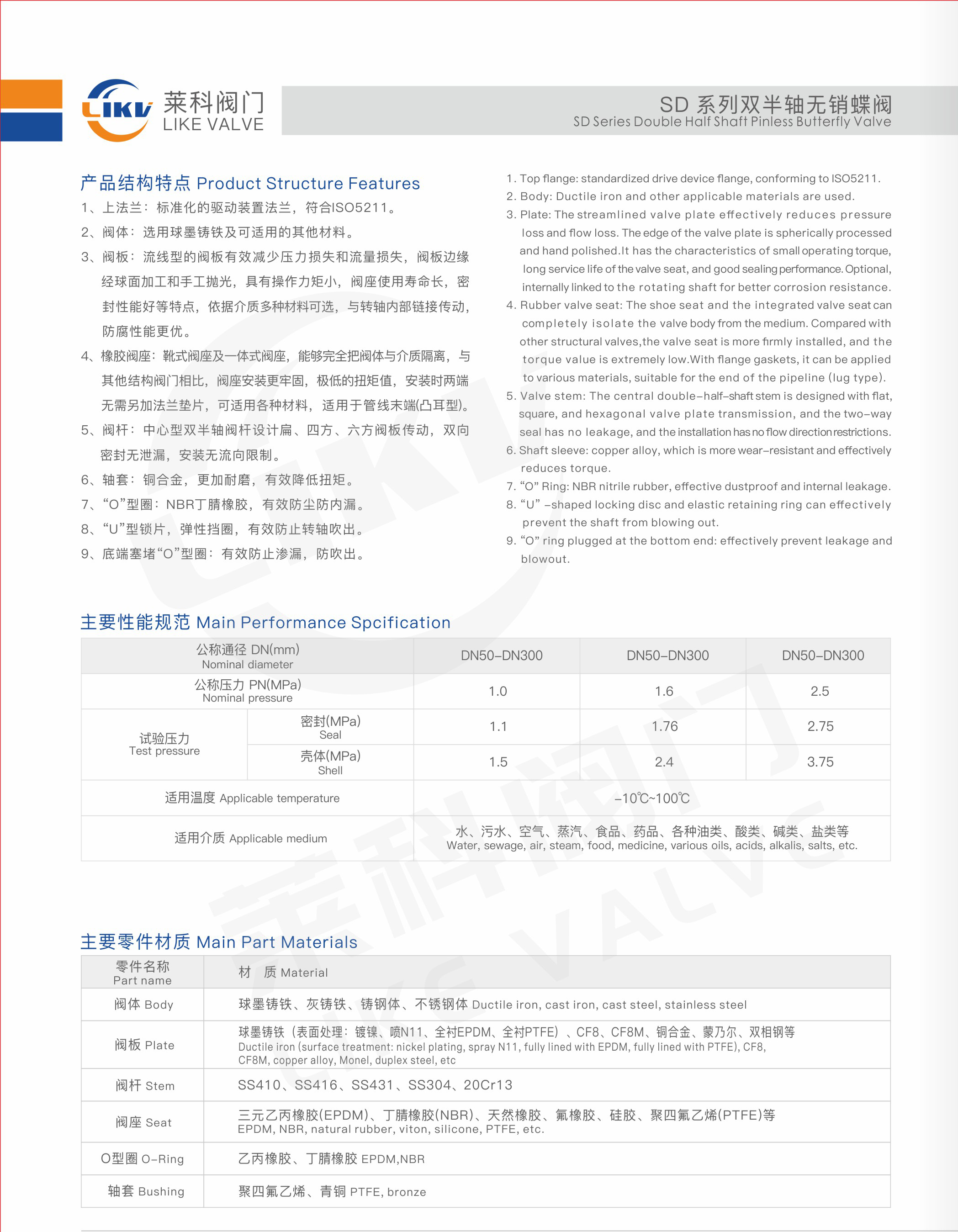

As a typical valve product, the working principle of Chinese double half shaft non pin butterfly valve mainly depends on the opening and closing methods of the butterfly valve. The Chinese double half shaft non pin butterfly valve adopts a double half shaft design, which enables good fluid control during the opening and closing process of the valve. At the same time, the no pin design reduces the internal friction of the valve, reduces operating torque, and improves the service life of the valve.

1. Opening process: When operating the Chinese double half shaft non pin butterfly valve, rotate the valve stem to gradually increase the gap between the valve stem and the valve seat. As the valve stem rotates, the valve plate slides along the valve seat, gradually opening the valve to achieve smooth flow of fluid.

2. Closing process: In contrast to the opening process, the valve is closed by rotating the valve stem counterclockwise to gradually bring the valve plate closer to the valve seat, until the valve plate is completely in contact with the valve seat.

2¡¢ Maintenance Strategy for Chinese Double Half Axis Non Pin Butterfly Valves

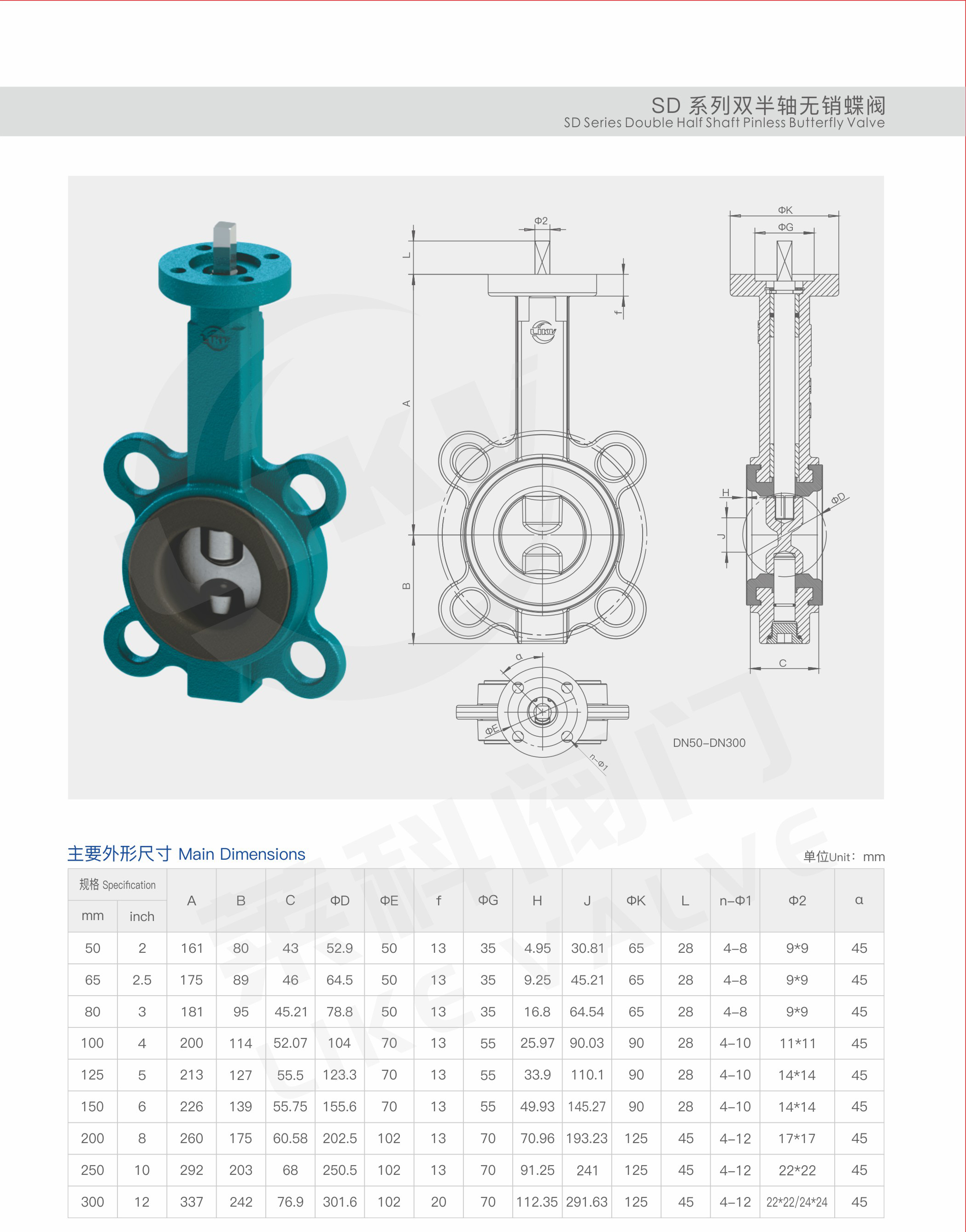

1. Choose the appropriate valve model: When purchasing a Chinese double half shaft pinless butterfly valve, choose the appropriate valve model based on the actual working conditions. For example, select the appropriate valve size and material based on factors such as fluid properties, flow rate, and working pressure.

2. Regular inspection of valve status: During the use of Chinese double half shaft non pin butterfly valves, it is necessary to regularly check the working status of the valve to ensure that it can open and close normally. At the same time, check the sealing performance of the valve and promptly identify and solve leakage problems.

3. Keep the valve clean: During the use of Chinese double half shaft non pin butterfly valves, the valve and its surrounding environment should be kept clean. To prevent impurities from accumulating inside the valve and affecting its normal operation.

4. Lubrication and maintenance: In order to reduce the operating torque of the valve and extend its service life, the valve transmission components should be lubricated regularly. Select appropriate lubricants and operate according to the maintenance manual provided by the manufacturer.

5. Regular replacement of seals: The seals of Chinese double half shaft non pin butterfly valves may suffer wear and tear during use, affecting the sealing performance of the valve. Therefore, it is necessary to regularly inspect and replace the seals to ensure the normal operation of the valve.

6. Valve maintenance and replacement: When the Chinese double half shaft non pin butterfly valve malfunctions, timely maintenance should be carried out. If the valve is severely damaged, it is necessary to consider replacing it with a new one based on the actual situation. When replacing valves, it is important to choose products with reliable quality and stable performance.

3¡¢ Conclusion

Chinese double half shaft non pin butterfly valves have a wide range of applications in the industrial field, and their maintenance work directly affects the service life and performance of the valves. By gaining a deep understanding of the working principle of China’s double half shaft non pin butterfly valve and adopting efficient maintenance strategies, we can ensure that the valve can still operate stably under harsh working conditions, creating greater value for the enterprise.

In China, with the continuous improvement of industrial automation, the market demand for double half shaft non selling butterfly valves is also increasing year by year. I believe that in the near future, the maintenance and upkeep technology of China’s double half shaft unsellable butterfly valves will become more mature, providing users with higher quality products and services.

Post time: Jan-08-2024