0102030405

API598 Hard Seal Lift Check Vavu

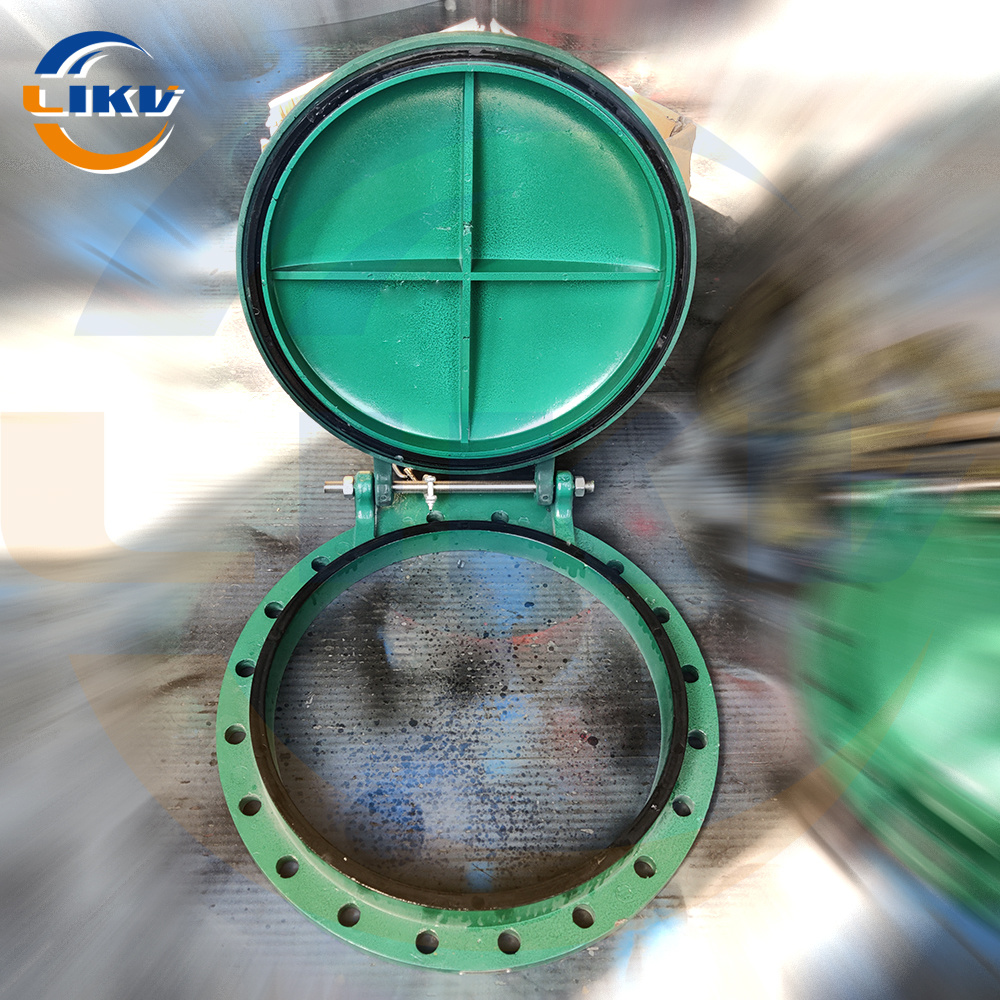

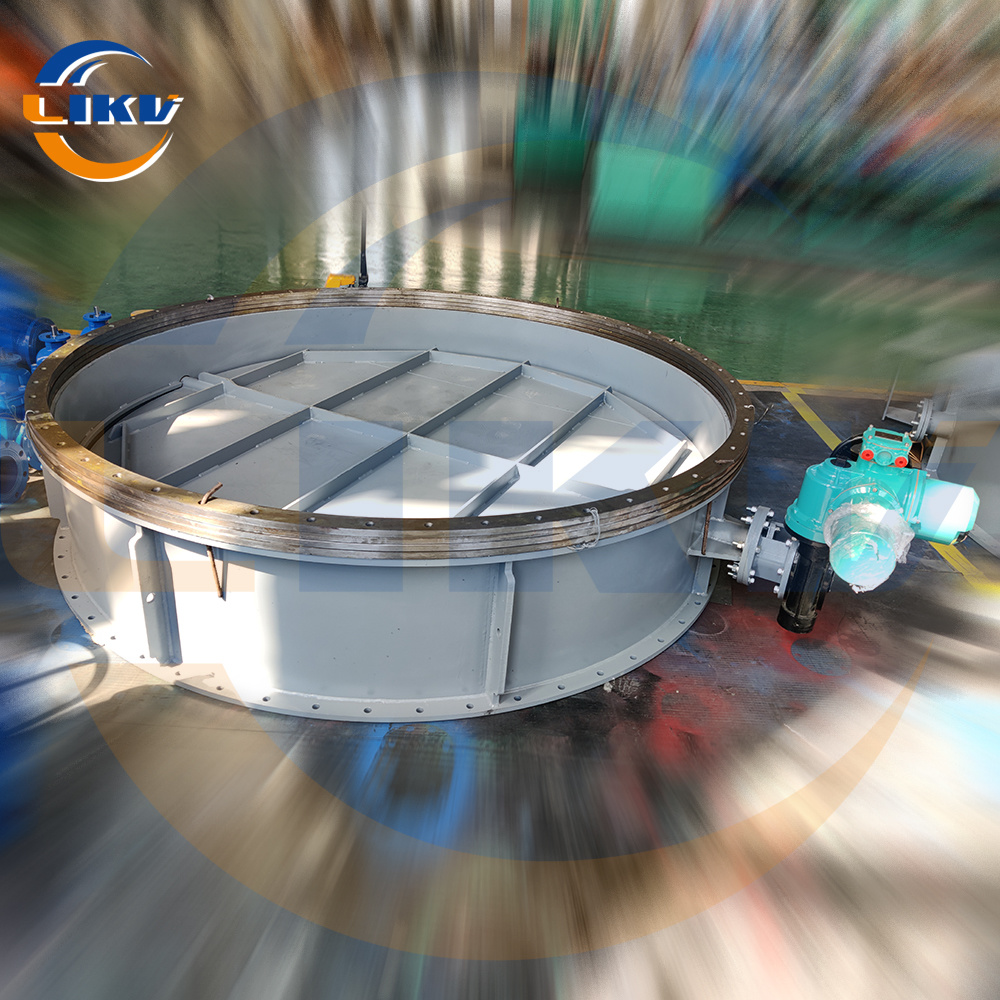

1. Mankhwalawa ali ndi dongosolo loyenera, kusindikiza kodalirika, kuchita bwino kwambiri komanso maonekedwe okongola; 2. Malo osindikizira a valve disc ndi mpando wa valve amakutidwa ndi Co based cemented carbide, yomwe ili ndi kukana kwabwino, kukana dzimbiri, kukana kukanda komanso moyo wautali wautumiki; 3. Zida za gawo ndi miyeso ya flange ndi gasket zitha kusankhidwa moyenerera malinga ndi momwe amagwirira ntchito kapena zofunikira za ogwiritsa ntchito kuti akwaniritse zosowa zosiyanasiyana zamainjiniya. Main ntchito specifications Design mfundo GB/T 12235 Pressure kutentha kalasi GB/T 12224 Kapangidwe kutalika GB/T 12221 Flange mtundu ndi kukula GB/T 9113, JB/T 79, EN1092, ASME B16.5/B 16.47 Kuyendera ndi mayeso JB/ T. mbali zazikulu No. Dzina la carbon zitsulo zosapanga dzimbiri zitsulo Aloyi zitsulo Low kutentha zitsulo 1 valavu thupi WCB CF8 WC6 LCB 2 Vavu chimbale WCB/25 CF8/F304 WC6/F11 LCB/LF2 3 shim Flexible graphite Flexible graphite Flexible graphite Valve graphite 4 chivundikiro WCB CF8 WC6 LCB 5 Chiphunzitso chachiwiri 35CrMoA 0Cr18Ni9(304) 25Cr2MoVA 35CrMoVA 6 Nut 45# 0Cr18Ni9(304) 35CrMoA 45# 7 Spring 60Si2Mn 48Ni 9(3Cr048Ni 9) 0Cr r18Ni9(304) Miyezo yayikulu yolumikizira DN(mm) LD D1 D2 bf Z- d H WT(kg) 15 130 95 65 45 16-2 4- 14 77 3 20 150 105 75 58 18-2 4- 14 77 4 25 160 168 4 81-81 4 122 18-3 8- 18 120 20 80 310 200 160 138 20-3 8- 18 130 30 100 350 220 180 158 20-3 8- 18 140 39 125 400 10 25-28 150 480 285 240 212 22-3 8- 22 180 70 200 600 340 295 268 24-3 12 22 215 161 250 730 405 355 320 26-3 12- 26 260 251 4812-300 6 315 395 Miyezo yayikulu yolumikizira DN(mm ) LD D1 D2 bf Z- d H WT(kg) 15 130 95 65 45 16-2 4- 14 100 3.4 20 150 105 75 58 18-2 4- 14 105 5 25 5 160 18-16 120 5.7 32 180 140 100 78 18-2 4- 18 130 9.1 40 200 150 110 88 18-3 4- 18 135 11.8 50 230 165 14 12 14 65 290 185 145 122 22-3 8 - 18 160 23 80 310 200 160 138 24-3 8- 18 169 30 100 350 235 190 162 24-3 8- 18 194 44 125 4002 26-27 5 150 480 300 250 218 28- 3 8- 22 255 99 200 600 360 310 278 30-3 12- 22 305 190 250 730 425 370 335 32-3 12- 26 355 385 305 304 - 26 410 450 Products Details Process Application