0102030405

I-Carbon steel electric manual blind valve F9T43X-0.5 ifanelekela igesi yesitshalo samandla kagesi intuthu fan-push induku yohlobo lwezibuko zikagesi valvu, ukucaciswa kwe-DN300-DN2000

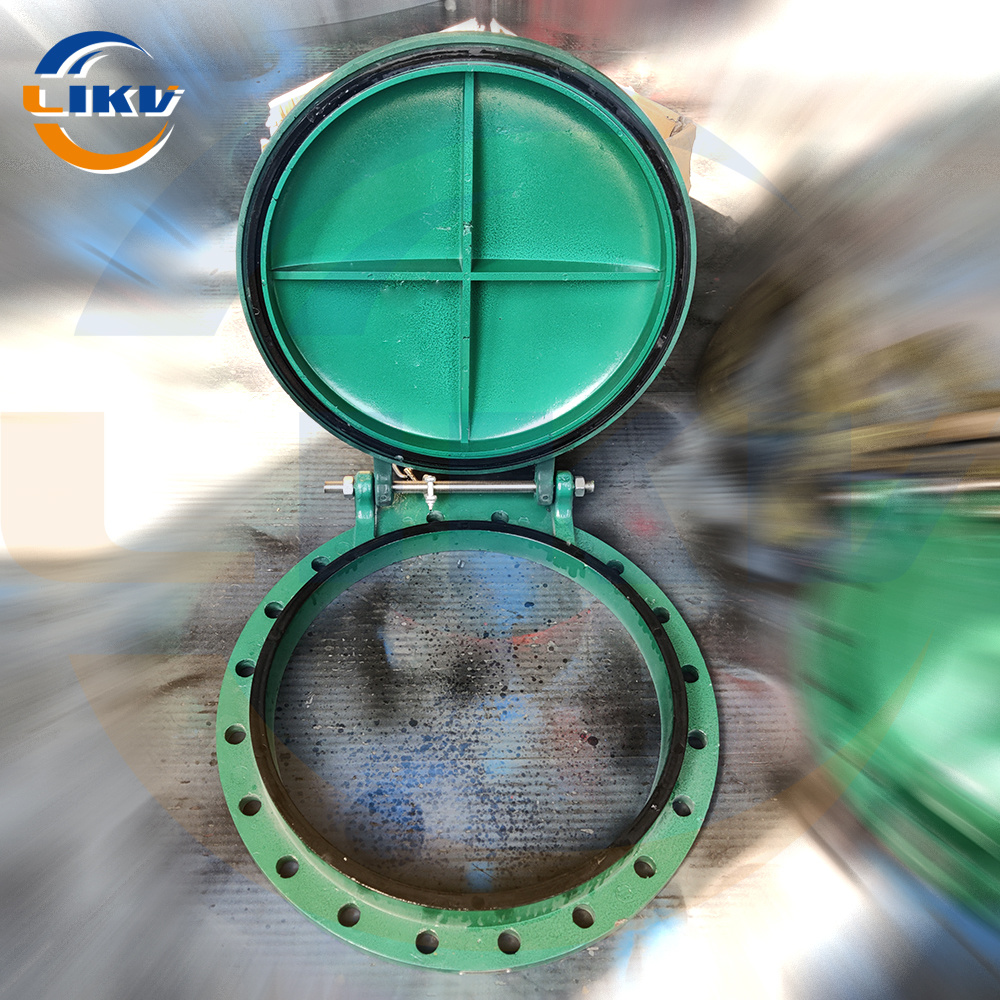

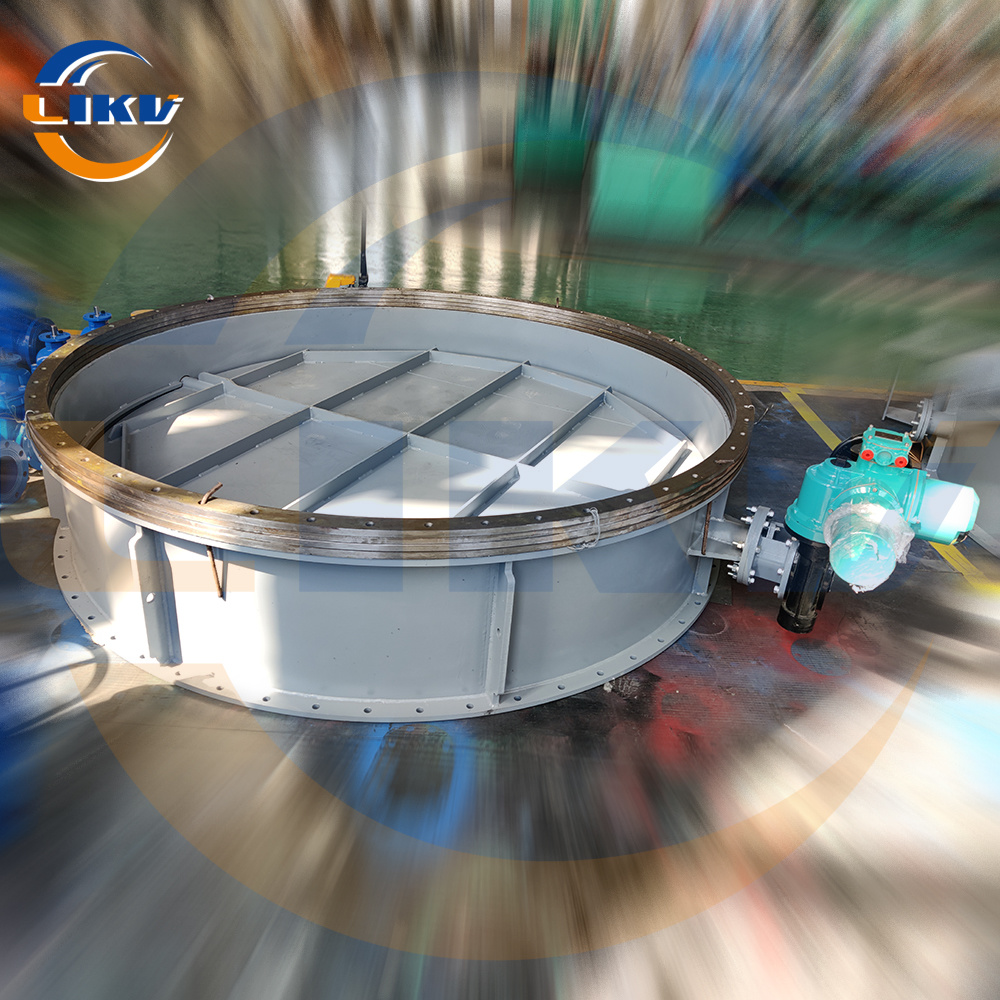

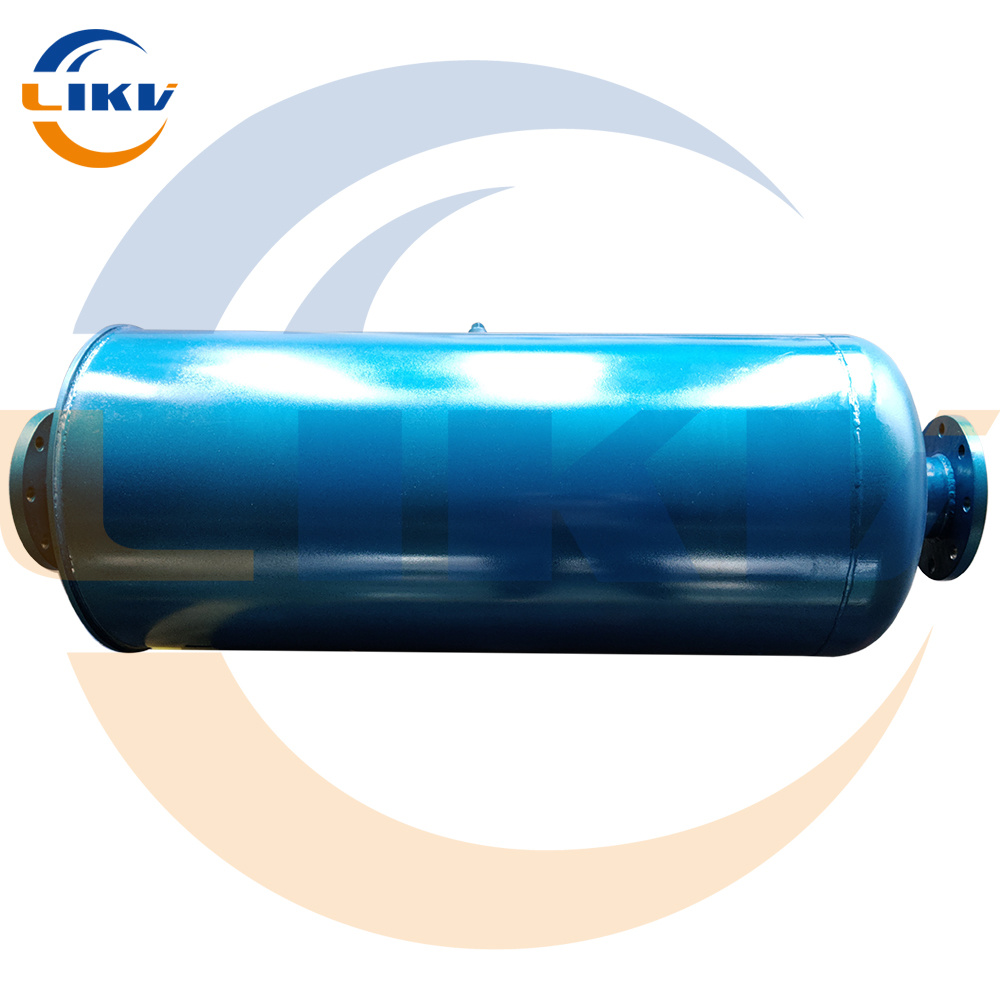

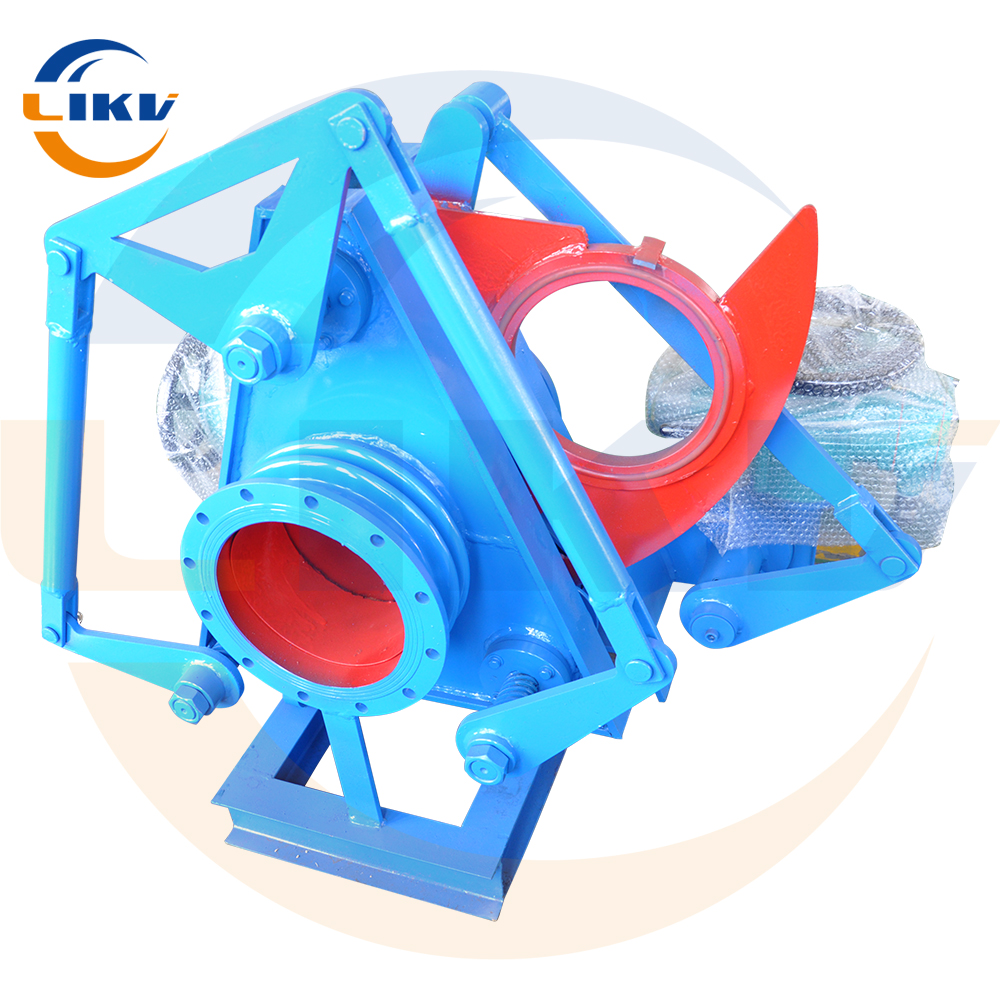

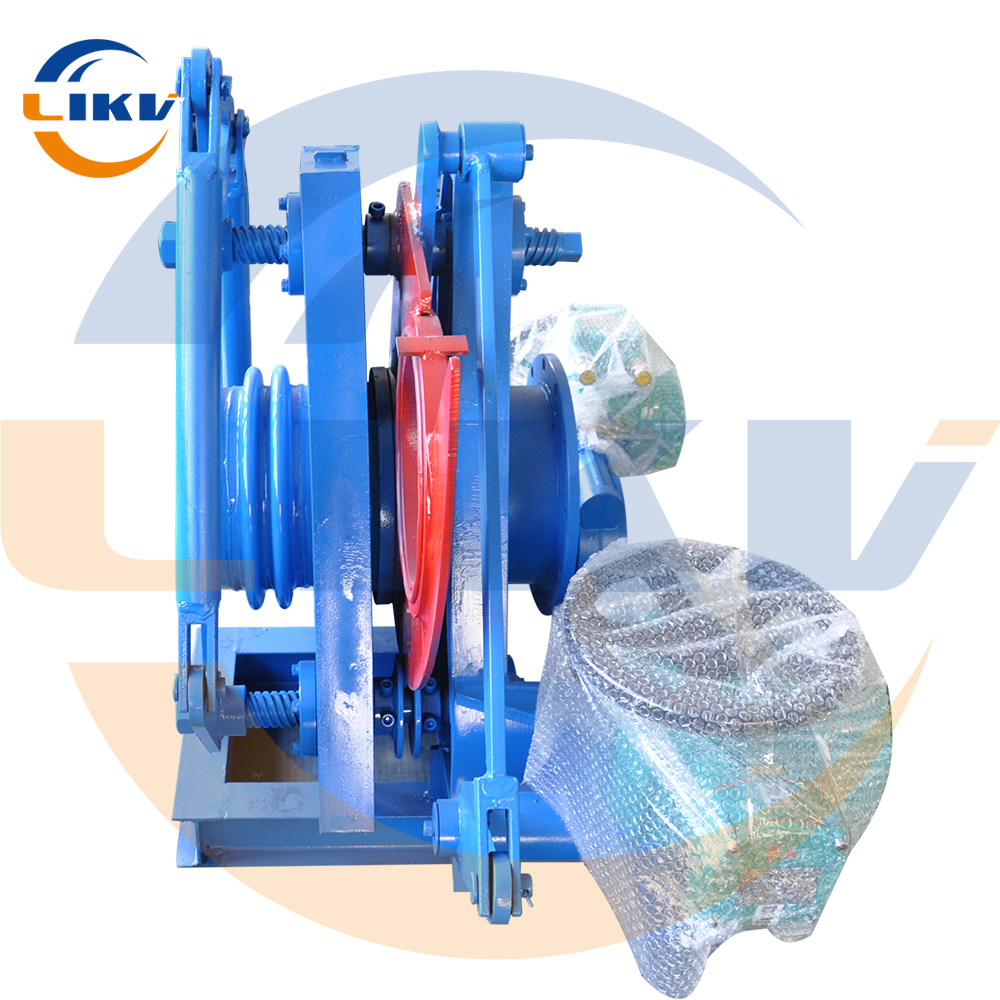

Imiyalelo Yokusetshenziswa Kwevaluvu Yepuleti Eyimpumputhe Lolu chungechunge lwama-valve epuleti eliyimpumputhe lwe-radial ngokuyinhloko lwakhiwe umzimba wevalvu yesokunxele, umzimba wevalvu yesokudla, ipuleti levalvu, iringi yokuvala irabha, ipheya ye-screw-nut, ugesi, umoya womoya noma umshini wokudonsa amanzi. Futhi iqukethe ikholomu yesisekelo neyokusekela ukwakha isakhiwo esiqinile. Ngesikhathi sokufakwa kwensimu, akuvunyelwe ngokuphelele ukususa isisekelo, ikholomu yokusekela nezinye izesekeli. I-valve ifakwe induku yokuvula nokuvala kanye ne-flap push rod. I-push rod yokuvula neyokuvala ishayela ipheya ye-screw-nut endleleni yokuxhuma ukuze kuqedelwe isenzo sokugoqa nokungafihli somzimba wevalvu. I-flap push rod ishayela i-valve plate ukuze iqedele isenzo sokushintsha sembobo nembobo eyimpumputhe. Ukushaywa kwe-push rod yokuvula nokuvala kanye ne-flap push rod kulawulwa iswishi yokulawula ukuhamba ku-push rod. I-valve ifakwe isinxephezelo sensimbi engagqwali, esibophezelekile kuphela ngokuvula nokuvala i-valve futhi ayivunyelwe ukufaka esikhundleni sesinxephezelo okufanele sifakwe epayipini. Isinxephezelo esihlukile kufanele sifakwe epayipini, ngaphandle kwalokho, amandla angaphandle akhiqizwa ukunwetshwa nokufinyezwa okushisayo noma ukwelula nokusonteka kwepayipi kuzodluliselwa kule valve, okuholela ekuphusheni, ukudonsa, ukusonteka nezinye izenzo ku-valve, ngaleyo ndlela kuthinte ukusebenza kwe-valve. Ngemva kokufakwa kwale valve, sicela ukhulule noma ususe amabhawodi amathathu okulungisa kusinxephezelo ukuze ugweme ukuthikameza ukusebenza kwesandiso sesinxephezelo phakathi nokusebenza. Ngemuva kokufakwa kwalesi valve, ukuthunywa kufanele kwenziwe. Okokuqala, sebenzisa imanuwali ukuze uxegise induku yokuvula nokuvala ibe indawo evuleke uhhafu, bese uxhuma intambo yamandla enjini kanye nentambo yokulawula ukushintsha kohambo, ngemva kokunika amandla, hlola ukuthi injini izungeza iye phambili noma ihlehle futhi ukuthi iswishi yohambo yenza ngokunembile yini. Ngemva kokunika amandla kulungile, hlola ngokulandelanayo ukuthi ingabe ivalvu isendaweni exegayo futhi ivaliwe lapho iswishi yohambo yenza ngokunembile. Uma zingavumelanisi, ukulungiswa kufanele kwenziwe. Ngemuva kokulungiswa izikhathi ezingu-2-3, khulula i-valve bese ulungisa ngokuvumelana nezinyathelo ezifanayo nezingenhla ze-flap push rod (kunconywa ukuthi umuntu oyedwa alawule inkinobho yokuhamba endaweni ye-valve futhi umuntu oyedwa alawule inkinobho kusilawuli. indawo ngesikhathi sokulungiswa kwe-valve, ukuze bakwazi ukubambisana ukuze balungise futhi uma kwenzeka behluleka, banqamule amandla ngesikhathi, basuse iphutha bese bephinda benza ukuthunywa). I-inlet ephakathi yale valve iseceleni ngaphandle kwesinxephezelo, futhi i-outlet ephakathi ihlangothini elinesinxephezelo; ukunakwa kufanele kukhokhwe kuso ngesikhathi sokufakwa. Le valve iyi-valve yohlobo oluvulekile, ngesikhathi sokuvula nokuvala, kuzoba nokuvuza kwemidiya, izinyathelo zokuphepha kufanele zithathwe ngesikhathi sokusebenza. Kunconywa ukuthi ufake i-valve ye-butterfly eqinile ngaphambi nangemva kwale valve ukuze unciphise ukuvuza kwemidiya ngesikhathi sokuvula nokuvala. Ngesikhathi sokusebenzisa le valve, kufanele ihambisane nemigomo yokuhlola njalo, ukulungiswa, ukugcotshwa nokugcinwa kwe-lubrication ukuze kunwetshwe impilo yayo yesevisi nokugcina isimo esihle sokusebenza. Inothi Elikhethekile: Ubakaki we-chassis onikezwe le valve awuvunyelwe ukuhlakazwa noma ukukhishwa ngesikhathi sokufakwa, futhi iplatifomu yokusebenza kufanele yengezwe ngaphansi kukabakaki ukuze kulungiswe i-chassis ngesikhathi sokufakwa, ngaphandle kwalokho izobhubhisa ukusebenza okuphelele kwe-valve futhi ibangele. ayikwazi ukusetshenziswa ngokujwayelekile, amacala abucayi angaholela ngisho nasekukhishweni kwe-valve yonke. Izicaciso Zokusebenza Eziyinhloko Imodeli Yomkhiqizo F643X-0.5 F743X-0.5 F9T43X-0.5 I-Nominal Diameter DN 300-1200 300-2000 300-2000 Nominal Pressure MPa 0.05 0.05 0.05 Ukubeka uphawu 0.5 MPa MPa 0.075 0.075 0.075 Actuating Source Umoya ocindezelwe 0.4-0.6MPa Amafutha okucindezela 4-6MPa 3-isigaba 380V50HZ Operating Temperature℃ -20℃-120℃ -20℃-200℃ Isikhathi sokuvula/Ukuvala/Amasekhondi ≤60 imizuzwana