Correct operation of Chinese flange connected centerline butterfly valves to extend their service life

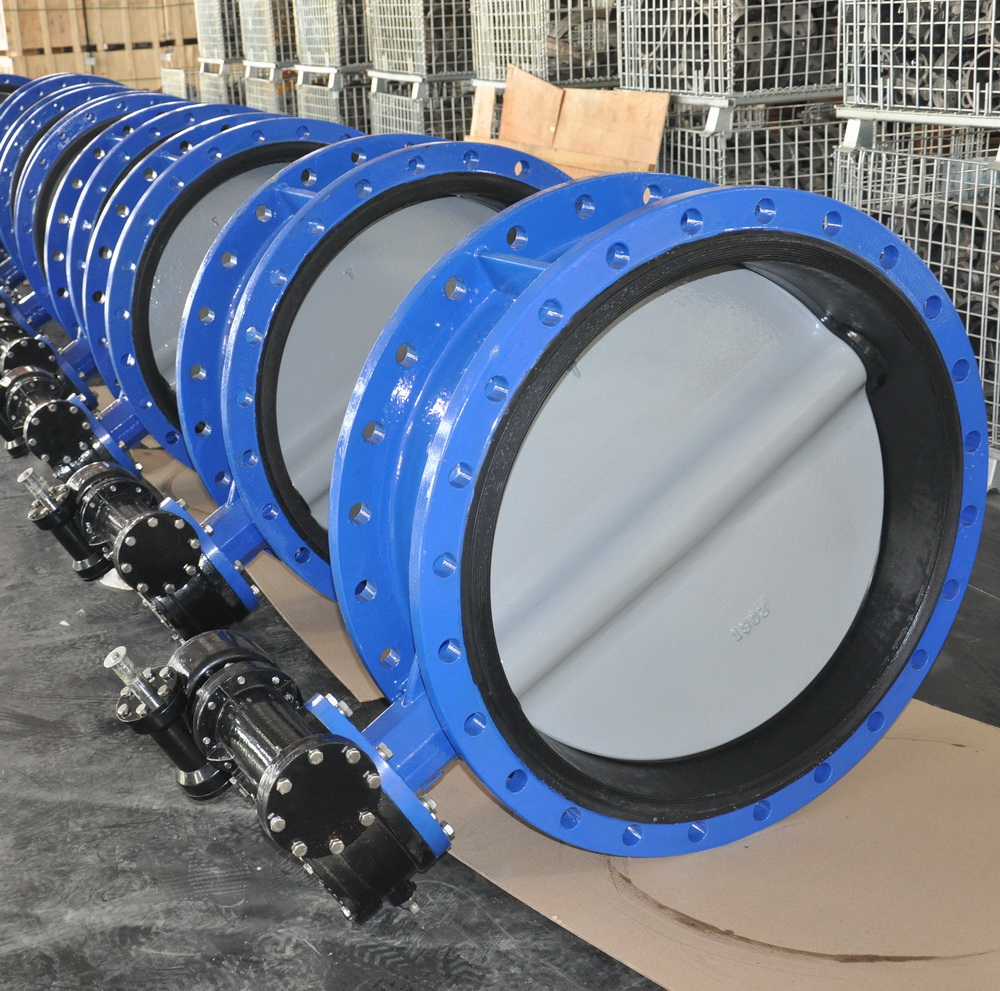

The Chinese flange connected midline butterfly valve is an important valve widely used in various working conditions, and its excellent performance and long service life make it occupy an important position in industrial production. However, in order to fully leverage the advantages of Chinese flange connected midline butterfly valves and extend their service life, correct operation and maintenance are essential. This article will provide a detailed introduction to how to correctly operate the Chinese flange connected centerline butterfly valve to extend its service life.

1、 Inspection before installation

Before installing the Chinese flange connected centerline butterfly valve, a comprehensive inspection should be conducted, including whether the valve model, specification, material, etc. meet the design requirements, whether the valve is damaged or defective, and whether the sealing surface of the valve is intact. Only by ensuring the quality of the valve can its stability and reliability be ensured during use.

2、 Correct installation

When installing Chinese flange connected centerline butterfly valves, the installation guidelines provided by the manufacturer should be followed to ensure that the installation position, direction, and method of the valve are correct. At the same time, attention should be paid to the connection method between the valve and the pipeline to ensure firm connection and prevent valve leakage caused by loose connection.

3、 Correct operation

1. Opening and closing the valve: When opening and closing the Chinese flange connection center line butterfly valve, it should follow the valve’s operating instructions to avoid using excessive force or speed to prevent damage to the valve.

2. Adjust flow and pressure: When adjusting the flow and pressure of the Chinese flange connection centerline butterfly valve, it should be gradually adjusted to avoid sudden and significant adjustments to prevent impact on the valve.

3. Regular inspection: During the process of using Chinese flanges to connect the centerline butterfly valve, it is necessary to regularly inspect it, including the sealing performance, operational performance, appearance, etc. of the valve, and promptly identify and handle problems.

4、 Maintenance and upkeep

1. Cleaning: Regular cleaning should be carried out on the Chinese flange connection center line butterfly valve to remove dirt and impurities inside and outside the valve, in order to prevent corrosion to the valve.

2. Lubrication: For valve components that require lubrication, lubricating oil should be added regularly to maintain good lubrication and reduce wear.

3. Replace vulnerable parts: For vulnerable parts of the valve, such as sealing rings, valve seats, etc., regular inspection and replacement should be carried out to ensure the normal operation of the valve.

In summary, correct operation and maintenance are the key to extending the service life of Chinese flange connected midline butterfly valves. Only by conducting pre installation inspection, correct installation, correct operation, and maintenance of valves can the performance of Chinese flange connected midline butterfly valves be fully utilized, their service life be extended, and reliable guarantees be provided for industrial production.

Post time: Nov-15-2023