Notes on the Use of Double Half Axis Non Pin Butterfly Valves in China: Leaders of a Butterfly Valve Revolution

�

This article will delve into the usage precautions of Chinese double half shaft non pin butterfly valves, compare the advantages and disadvantages of other valves, and reveal their unique advantages in industrial applications. The article will comprehensively analyze the structure, working principle, scope of application, and usage precautions, providing readers with a new perspective on valve selection.

1¡¢ Introduction

In modern industrial fields, valves are indispensable fluid control equipment. With the advancement of technology, valve products are constantly being updated to meet increasingly stringent engineering requirements. Among numerous valve products, China’s double half shaft unsellable butterfly valve stands out, becoming a popular product in the valve market due to its unique structure, excellent performance, and wide application range. This article will focus on the usage precautions of Chinese double half shaft non pin butterfly valves, revealing their advantages in industrial applications.

2¡¢ Comparison between Chinese Double Half Axis Non Pin Butterfly Valves and Other Valves

1. Traditional butterfly valve

Although traditional butterfly valves have a simple structure, they have many shortcomings in practical applications. For example, the valve stem of traditional butterfly valves is prone to damage, and the valve is not tightly closed, resulting in leakage. In addition, traditional butterfly valves are mostly driven manually, which is inconvenient to operate and cannot achieve remote control.

2. Ball valve

Ball valves are widely used in the field of fluid control, but their structure is complex and their manufacturing cost is high. In addition, the sealing performance of ball valves is greatly affected by temperature and pressure, which cannot guarantee long-term stable operation.

3. Gate valve

Gate valves have a large flow area and are suitable for controlling high viscosity and granular substances. But the structure of gate valves is complex, with a large opening and closing torque, making operation difficult. Moreover, the leakage problem of the gate valve has not been effectively resolved.

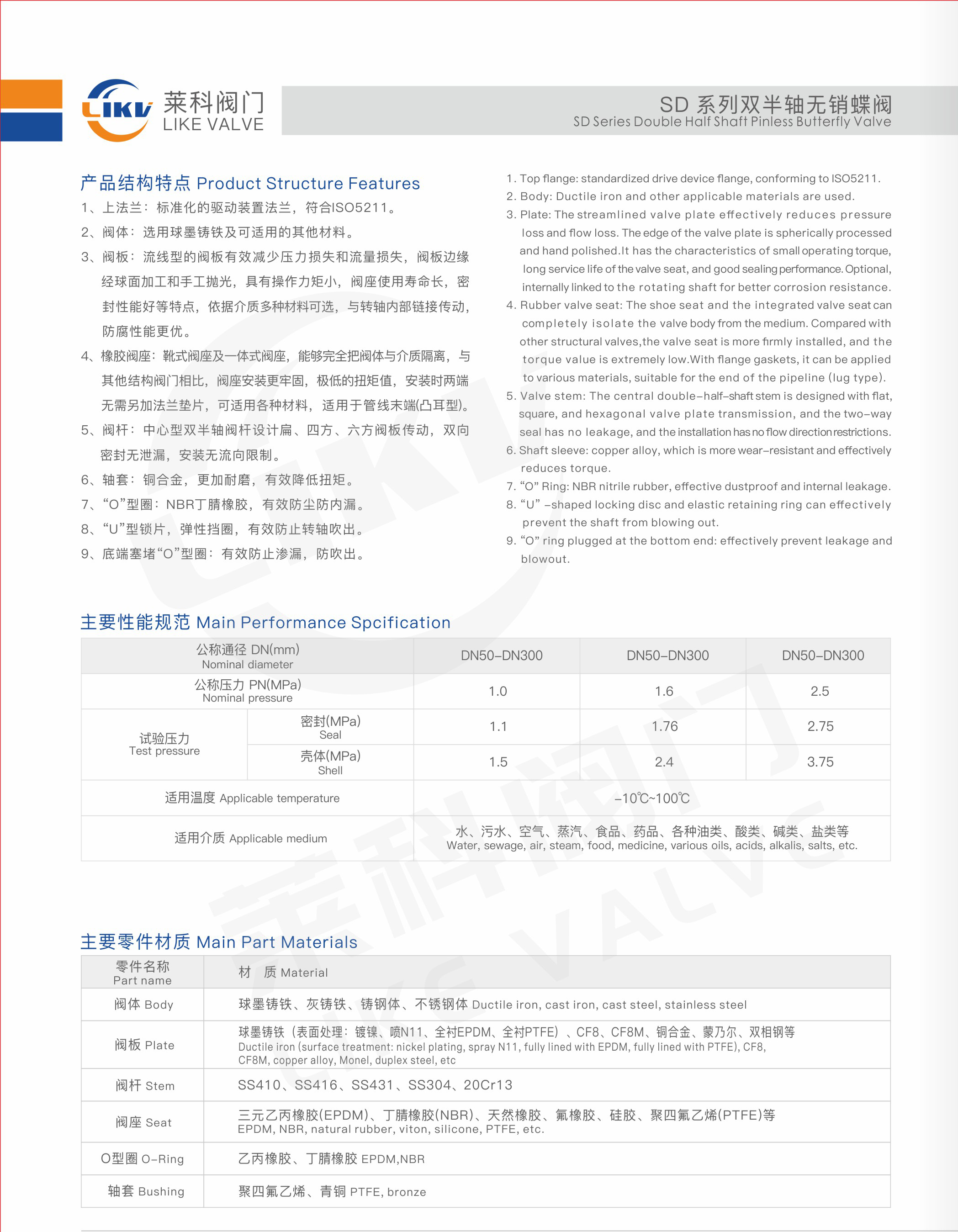

4. Chinese double half shaft non pin butterfly valve

Compared with traditional butterfly valves, ball valves, and gate valves, Chinese double half shaft non pin butterfly valves have the following advantages:

(1) Simple structure: The Chinese double half shaft non pin butterfly valve adopts a unique double half shaft design, eliminating the valve stem, making the valve structure simpler.

(2) Superior sealing performance: The sealing structure of the Chinese double half shaft pinless butterfly valve adopts a combination of soft and hard, which can ensure sealing performance and adapt to wear under different working conditions.

(3) Convenient operation: The Chinese double half shaft pinless butterfly valve adopts electric drive, which can achieve remote control and is more convenient to operate.

(4) Widely applicable: The Chinese double half shaft non pin butterfly valve is suitable for various fluid media, including high viscosity and granular substances, and can operate stably under harsh working conditions.

3¡¢ Precautions for the use of Chinese double half shaft non pin butterfly valves

Before installation, the integrity of the valve and driving device should be carefully checked to ensure that there is no damage.

During installation, the valve should be perpendicular to the pipeline to ensure proper operation.

3. During the opening or closing process of valves, violence should be avoided to avoid damaging the sealing components.

4. Regularly check the operation status of the valve and promptly handle any abnormalities found.

5. When the valve is reactivated after long-term shutdown, it should be cleaned and lubricated to ensure the normal operation of the valve.

6. Attention should be paid to the maintenance and upkeep of valves to extend their service life.

4¡¢ Conclusion

With its unique structure, superior performance, and wide range of applications, Chinese double half shaft non pin butterfly valves have broad market prospects in the industrial field. Through the introduction of this article, I believe that everyone has a deeper understanding of Chinese double half shaft non pin butterfly valves. In practical applications, suitable valves can be selected according to needs to ensure the smooth progress of the project. At the same time, attention should also be paid to the use and maintenance of valves to fully leverage their performance advantages. I hope this article can provide useful references for valve selection and application.

Post time: Jan-09-2024