Selection of gate valves in the process of water supply and drainage construction

Gate valve used for a long time, do you know how to ensure the tightness of the gate valve? Strictly control the purchase process and make careful inquiries. Record the application of pipe fittings and pipes of all batches and replace them immediately once any doubt is found. For PPR pipe devices, the ductility of the solution to take measures to prevent. Technical methods can be used: non – directly buried pipeline laying, should consider the solution of the pipeline thermal expansion and cold contraction deformation of technical methods. The ductility of the pipeline should be compensated by the folding arm of the pipeline as far as possible; When piping can not be used as natural compensation, other compensation methods should be used.

Water supply and drainage engineering construction process often encountered drainage pipe pipe blockage, pipe leakage, gate valve selection and device, noise and other questions, the network for everyone to analyze the factors of this question, and clearly put forward prevention methods and solutions.

1. The avoidance and solution of drainage pipeline blockage question

Factors: the blockage of the drainage pipe in the room is a common quality fault in the construction of the construction device, which is the old question that the pipe device and civil engineering cooperation can not solve. In the process of cross construction of civil engineering and installation, there are many cases of pipe blockage, especially the drain pipe opening and deodorant floor drain in clean room. Even when the pipe is installed and the branch pipe is closed with cement slurry, it is often opened by others to serve as an outlet for cleaning the waste water from the concrete and flat surface. Some even fall into wood, sand and gravel, waste, cement mortar and so on from the roof ventilation pipe mouth and rainwater bucket, resulting in pipe blockage. Light consumption of labor transmission, heavy chisel on the concrete ground, rework to cancel the pipeline from scratch device, then both consumption of labor and material, and harm the construction period. Some drainage pipes have some blockage in the cavity of the pipe, which can not be treated in time in the process of pressure test and water delivery. After the investment of capital, it will inevitably show the blockage of the pipe and harm the customer application.

Prevention and solution: in order to prevent the blockage of the pipeline in the process of cross construction, in addition to the application of the heart through the pipe cavity, remove dirt, effectively according to the standard accurate application of drainage pipe parts; Device line, should guarantee the slope and the overall planning and standard requirements, and a drain crossing by adopting the way of mixed slurry seal, also be sure to take as shown in the various technical measures to prevent pipe plugging: due to the building structure factors, when the word with a b on the riser tube, should according to the specification requirements, set in the top of the tube b word query mouth is easy to repair; When there is no requirement in the overall planning, the cleaning port should be set in the waste water cross pipe with 2 or more than 2 excreta devices or 3 or more than 3 cleaning equipment according to the engineering construction and inspection standards. The query port or cleaning port should be set on the waste water cross pipe with less than 135 degrees at the corner. Device for drainage pipeline buried temporarily not discharged tube and vertical pipe, pipe in mouth of riser query inserted end plate or other way to prison, and immediately make up the riser wear 2 concrete floor hole, after being approved on fixed riser, revocation of temporary support, this branch should try to reduce the civil engineering as a temporary wastewater discharge entrances and exits. In the civil engineering decoration design after the end of the root, before the water supply and drainage clear application riser device, for the bottom layer and two more than the pipeline for irrigation test query, confirm that each pipe section is communicated, and then use direct sleeve (pipe) tube will query the mouth pipe and the bottom of the discharge pipe docking.

2, the avoidance and solution of pipeline leakage question

Pipeline leakage question is water supply and drainage pipeline engineering construction is more common doubt, the factors of this question are more, the avoidance and disposal of this question is an important link of concern for water supply and drainage engineering construction, strict requirements for the tightness of the pipeline management system around all engineering construction process.

Factors: the question of pipeline leakage can be analyzed from the two levels of raw materials and the actual operation of engineering construction. Raw materials: The factors of raw materials include: the compressive strength of pipe fittings and pipes is not up to standard; Pipes and pipes have sand holes; The pipe installation was later damaged by human factors. This situation has been touched by the creators, the quality of the galvanized pipe is more of the elbow, this kind of residual elbow is mainly the wall thickness of the inner arc is too thin or sand hole, the human eye is usually difficult to find. The quality of plastic pipe materials is usually very good, and the leakage factor is usually caused by the destruction of the installation by other technical work crews. Engineering construction practical operation level: engineering construction field factors include: galvanized pipe thread processing is not pass; Pipe socket joint is not tight. This is also a common factor. The leakage of drainage pipe socket is very few. Most of the factors that show this kind of question are careless engineering construction. When the pipeline is connected, it is not good to forget the glue or stab deep. Deep markup, easy to manipulate and easy to query.

Prevention methods and solutions: strictly control the purchase process, careful inquiry. Record the application of pipe fittings and pipes of all batches and replace them immediately once any doubt is found. For PPR pipe devices, the ductility of the solution to take measures to prevent. Technical methods can be used: non – directly buried pipeline laying, should consider the solution of the pipeline thermal expansion and cold contraction deformation of technical methods. The ductility of the pipeline should be compensated by the folding arm of the pipeline as far as possible; When piping can not be used as natural compensation, other compensation methods should be used. There should be compensation for leveling mains to leveling risers, leveling mains to risers, and risers to layers without affecting each other when the ductility of the pipe is extended. When installing horizontal pipe or riser pipe, the indoor space should be built adequately, and the “U” shaped pipe should be used to compensate for deformation. Show water leakage questions, looking for water seepage point, looking for water seepage point after analysis of factors. Subsequently, relevant measures were taken to solve the problem: replace the unqualified pipe fittings and pipes; If the actual operation of engineering construction does not pass the standard, it will be reworked and manufactured from scratch. Due to the PPR pipe produced by thermal expansion and cold contraction, cut off a section of pipe to adopt the above technical measures to carry out rectification.

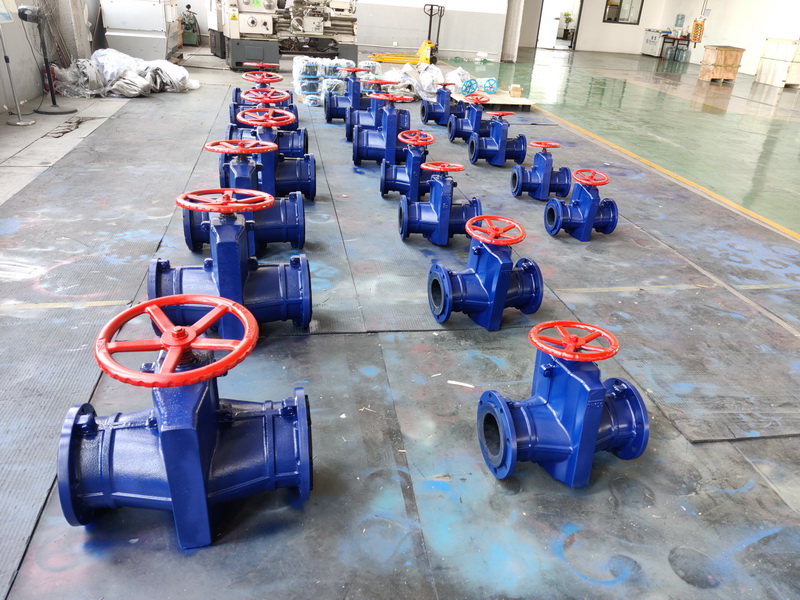

3, the selection and installation of gate valve and prevention methods

Production factors: unreasonable selection of gate valve types: valve type and pipeline management system function and working pressure are not matched, globe valve and globe valve mixed use, disc valve and valve mixed use, Angle globe valve and globe valve mixed use, stem valve and dark stem valve mixed use, pipeline operation and maintenance have adverse effects. Gate valve assembly not suitable for practical operation and maintenance. Check valve device position is unreasonable and other questions.

Prevention methods: when the device to consider the actual operation and maintenance of indoor space, pay attention to the relative height of the device and rocker house orientation; If two gate valves are connected immediately and the gap between the anchor bolts is short, a pipe hoop should be added between the two valves. Check valves must be identified by the arrow. The check valve of the outlet of the low water storage tank should be levelled at more than 1m away from the water bottom tank to facilitate the accurate posture of the check valve, or the use of low friction resistance check valve.

4, noise question factors and solutions

Generation factors: when the working pressure of water supply and drainage pipeline exceeds 0.3-0.4mpa and the pipeline length is ≤20mm and the pipeline is long, the pipeline will produce noise and vibration, which is mainly caused by the co-vibration generated by the driving force of fast water and the pipeline management system. Drainage pipe pipe noise question: drainage pipe water is not full and force flow, noise is inevitable, and by the pipeline material harm. Experimental raw materials show that when the total flow of DN100 pipe is 2.7L/s, the noise value of cast iron drainpipe is 46.5dB, and the noise value of PVC-U pipe is 58dB. Therefore, soft butt cast iron drainpipe should be used in high-end rooms requiring quietness. New fiberpipe polyurethane foam noise reduction PSP pipe, sound insulation effect is very good, the price is slightly expensive, can also be used.

Prevention methods: carding prevention methods include appropriately increasing the pipe, using flexible rubber soft joint, adding rubber plate between the support frame and the pipeline and refitting pressure regulating valve, etc. But pay attention to the pressure regulating valve itself is also noisy, to be repeatedly adjusted to reduce the noise to minimum.

Gate valve used for a long time, do you know how to ensure the tightness of the gate valve?

Piston and high pressure gate valve protrusions can be damaged and seals reduced after prolonged service. Repairing the protruding surface is a large and critical work. The specific method of repair is grinding. For the more serious damage of the protruding surface, it is first sprayed welding after nc processing and then grinding.

Post time: Jun-15-2022