The application of large diameter ventilated butterfly valve in industrial valves

(1) Connect the valve with thread. This CONNECTION IS USUALLY MADE BY MACHINING

ALVE INLET AND OUTLET ENDS INTO TAPERED OR STRAIGHT PIPE THREADS THAT CAN BE CONNECTED to TAPERED PIPE THREAD JOINTS OR LINES. Because of the possibility of large leakage channels in this connection, these channels can be blocked with sealant, sealing tape, or packing. If the material OF the valve body can be welded, but the coefficient of expansion is very different, or the range of variation of the operating temperature is large, the threaded connection must be honey sealed welding.

Threaded connection of the valve is mainly the nominal meridian in the following 50mm valve. If the diameter size is too large, it is very difficult to install and seal the joint.

To facilitate installation and removal of threaded valves, connectors are available at appropriate locations in the piping system. Valves up to 50mm in nominal size may use a sleeve joint as a joint, with threads connecting the two parts of the joint.

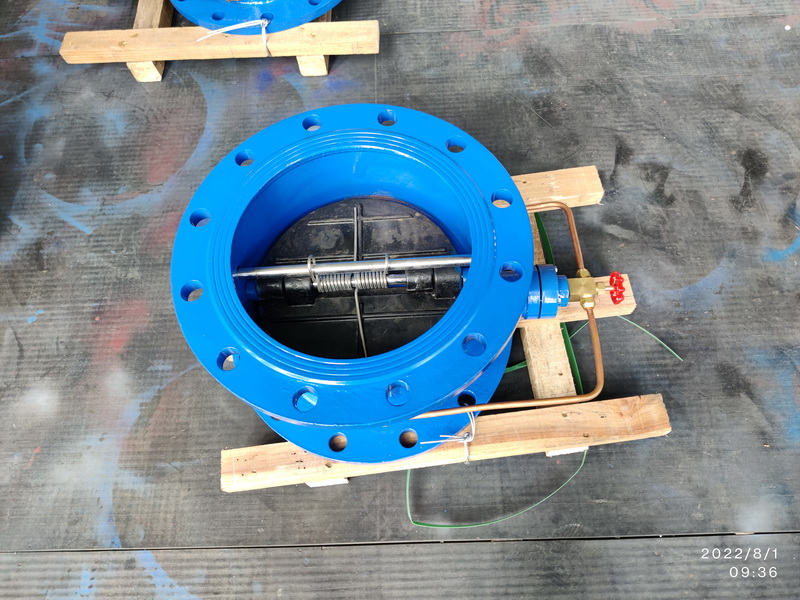

(2) Flange connection valve. Flanged valves are easy to install and remove. But they are bulkier than threaded valves, and correspondingly more expensive. Therefore, it is suitable for pipe connection of various sizes and pressures. However, when the temperature exceeds 350 degrees, due to the loosening of bolts, gaskets and flanges, which also significantly reduces the load on the bolts, leakage may occur to the heavily stressed flange connections.

(3) Weld the valve. This connection is suitable for all kinds of pressure and temperature, and is more reliable than flanged connection when used under heavy conditions. But the welded valve disassembly and reinstallation are more difficult, so its use is limited to usually can run reliably for a long time, or use conditions of loading, high temperature occasions. Such as thermal power station, nuclear energy project, ethylene project on the pipeline.

Welded valves with nominal diameters up to 50mm usually have welded jacks to hold the pipe at the flat end of the load. Because socket welding forms a gap between the socket and the pipeline, which may cause the gap to be corroded by some media, and the vibration of the pipeline will make the joint part fatigue, so the use of socket welding is limited.

In the nominal diameter is large, the use of conditions of loading, high temperature, the valve body often adopts groove welding, at the same time, welding joint has the original requirements, must choose a strong technical welder to complete the work

Large diameter ventilation butterfly valve in the application of industrial valves At present our country various industries for metal valve, valve widely used in the production of metal valve used for hundreds of years of history, which has through improvement of structure and material, but by its own limitations, metal materials is more and more can not adapt to bad working conditions, such strong high wear and corrosion. Mainly reflected in the short service life, leakage seriously affected the stability of the system operation. The traditional metal valve is in urgent need of thorough innovation in material, design and manufacturing process.

At present, the valve commonly used in the production of various industries in our country is the metal valve. The use of metal valve has been over one hundred years of history. Although it has been improved by structure and materials, it can not meet the needs of high wear, strong corrosion and other harsh working conditions. Mainly reflected in the short service life, leakage seriously affected the stability of the system operation. The traditional metal valve is in urgent need of thorough innovation in material, design and manufacturing process.

Advanced ceramic material, as a new material in the 21st century, has been taken seriously by more and more scientific workers. It is a bold and beneficial innovation to apply it to industrial valves.

Ceramic materials have very little deformation and much higher binding strength than metals. Generally, the crystalline ionic radius of ceramic materials is small, and the ionic electricity price is high, and the coordination number is large. These properties determine the tensile strength, compressive strength, elastic modulus and hardness of ceramic materials are very high. Ceramic itself, however, “brittle” and difficult processing limits its scope of application of recent decades, due to the martensitic phase transformation toughening technology, composite material science and technology and the development and progress of the concept of nanometer ceramics made of pottery and porcelain “brittle” got * * to improve, the toughness and strength has been greatly improved, expanding application range.

Wear-resistant ceramic valve is mainly used in electric power, petroleum, chemical industry, metallurgy, mining, sewage treatment and other industrial fields, especially in the face of high wear, strong corrosion, high temperature, high pressure and other harsh working conditions, but also shows its best performance. It can meet the use of high wear, strong corrosion environment, especially the outstanding feature is long service life, its performance price ratio is far better than other similar metal valves. With the continuous development and progress of science and technology, ceramic materials from the formulation, molding, processing and assembly technology and other aspects of the technology is more mature and complete, ceramic valve with its excellent performance to get the recognition of people in the industry. The successful experience of making ceramic valves can also be applied to more advanced engineering fields.

Post time: Aug-05-2022