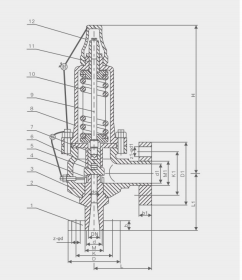

Spring micro relief valve

Product Detail

OEM/ODM Service

Product Tags

Material of main parts

| NO. |

Part name |

texture of material |

| 1 |

flange |

A42Y-160¡¢KA42Y-230 |

A42Y-160/320P |

A42Y-160/320R |

| 2 |

Valve seat |

35/35CrMoA |

20Cr13 |

1Cr18Ni1 2Mo2Ti |

| 3 |

valve body |

40 |

1Cr18Ni9Ti |

1Cr18Ni1 2Mo2Ti |

| 4 |

Regulating valve |

20Cr13 |

1Cr18Ni9Ti |

1Cr18Ni1 2Mo2Ti |

| 5 |

Valve disc |

20Cr13 |

1Cr18Ni9Ti |

1Cr18Ni1 2Mo2Ti |

| 6 |

Recoil plate |

20Cr13 |

1Cr18Ni9Ti |

1Cr18Ni1 2Mo2Ti |

| 7 |

Guide sleeve |

20Cr13 |

1Cr18Ni9Ti |

1Cr18Ni1 2Mo2Ti |

| 8 |

Valve cover |

ZG230-450 |

ZG230-450 |

ZG230-450 |

| 9 |

Stem |

20Cr13 |

1Cr18Ni9Ti |

1Cr18Ni9Ti |

| 10 |

Spring |

50CrVA |

50CrVACoated fluoroplastics |

50CrVACoated fluoroplastics |

| 11 |

Screw adjustment |

45 |

20Cr13 |

20Cr13 |

| 12 |

Valve cap |

ZG200-400 |

ZG200-400 |

ZG200-400 |

|

Sealing surface material |

Surfacing Co based cemented carbide |

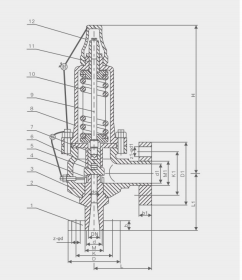

Main connection dimensions

Main connection dimensions

| model |

Nominal diameter |

d0 |

D |

M |

K |

D |

Z-¦µd |

b |

d1 |

M1 |

K1 |

D1 |

Z-¦µd |

B1 |

L |

L1 |

¡ÃH |

| A42Y-160 |

15 |

8 |

20 |

M24¡Ã2 |

60 |

98 |

3-18 |

20 |

29 |

M42¡Ã2 |

80 |

115 |

4-18 |

22 |

95 |

100 |

220 |

| 20 |

8 |

27 |

M33¡Ã2 |

68 |

105 |

3-18 |

20 |

29 |

M42¡Ã2 |

80 |

115 |

4-18 |

22 |

95 |

100 |

220 |

| 25 |

14 |

28 |

M33¡Ã2 |

68 |

105 |

3-18 |

20 |

50 |

M64¡Ã3 |

115 |

165 |

6-26 |

32 |

150 |

150 |

280 |

| 32 |

15 |

37 |

M42¡Ã2 |

80 |

115 |

4-18 |

22 |

50 |

M64¡Ã3 |

115 |

165 |

6-26 |

32 |

150 |

150 |

390 |

| 40 |

20 |

47 |

M52¡Ã2 |

115 |

165 |

6-26 |

28 |

65 |

M80¡Ã3 |

145 |

200 |

6-29 |

40 |

180 |

180 |

495 |

| 50 |

25 |

59 |

M64¡Ã2 |

115 |

165 |

6-26 |

32 |

80 |

M100¡Ã3 |

170 |

225 |

6-33 |

50 |

165 |

165 |

400 |

| A42Y-320 |

15 |

8 |

27 |

M33¡Ã2 |

68 |

105 |

3-18 |

20 |

29 |

M42¡Ã2 |

80 |

115 |

4-18 |

22 |

95 |

100 |

220 |

| 20 |

8 |

30 |

M33¡Ã2 |

75 |

110 |

3-18 |

22 |

29 |

M42¡Ã2 |

80 |

115 |

4-18 |

22 |

95 |

100 |

220 |

| 25 |

14 |

35 |

M42¡Ã2 |

80 |

115 |

4-18 |

22 |

50 |

M64¡Ã3 |

115 |

165 |

6-26 |

32 |

150 |

150 |

280 |

| 32 |

15 |

41 |

M48¡Ã2 |

95 |

135 |

4-22 |

25 |

50 |

M64¡Ã3 |

115 |

165 |

6-26 |

32 |

150 |

150 |

390 |

| 40 |

50 |

58 |

M64¡Ã2 |

115 |

165 |

6-26 |

32 |

65 |

M80¡Ã3 |

145 |

200 |

6-29 |

40 |

180 |

180 |

495 |

| 50 |

25 |

70 |

M80¡Ã2 |

145 |

200 |

6-29 |

40 |

80 |

M100¡Ã3 |

170 |

225 |

6-33 |

50 |

165 |

165 |

400 |

| A42Y-400 |

32 |

15 |

41 |

M48¡Ã2 |

95 |

135 |

4-22 |

25 |

50 |

M64¡Ã3 |

115 |

165 |

4-26 |

32 |

150 |

150 |

397 |

Previous: Electric rising stem wedge gate valve

Next: Dynamic balance intelligent valve