By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Europe style for China Double Flanged Pn16 Di Body Water Oil Gas Ductile Iron Medium D41 Butterfly Valve, We have been prepared to offer you the top suggestions on the designs of one’s orders in a professional way if you need. During the meantime, we retain on developing new technologies and building new designs so as for making you ahead within the line of this business.

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Butterfly Valve, China Valve, We now have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

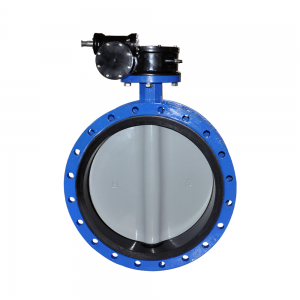

Product use

Flange fluorine lined butterfly valve is widely used for the transportation of liquid and gas (including steam) in various types of industrial pipelines, especially for the application of severely corrosive media, such as hydrofluoric acid, phosphoric acid, chlorine, strong alkali, aqua regia and other highly corrosive media.

Product features

1. Small volume and convenient installation

2. The center line butterfly valve is concentric (center line) between the whole butterfly plate and the valve seat within the circumference of 360 ℃, with two-way sealing function, and the pressure and flow can be adjusted freely;

3. Four stage loading elastic seal absolutely ensures zero leakage inside and outside the valve.

Product executive standard

| Product specification | design code | Structure length | Connecting flange | Test and inspection |

| GB/T12238 | GB/T12221 | GB/T9113 | JB/T9092 GB/T13927 | |

| EN593 API609 | EN558 API609 | EN1092 ASME B16.5/B16.47 | API598 |

Product performance specification

| model | Nominal pressure | Test pressure | working temperature | Applicable media | |

| housing | seal up | ||||

| D341F4-10 | 1.0 | 1.5 | 1.1 | -30~180 | Sulfuric acid, hydrofluoric acid, phosphoric acid, chlorine, benzene, strong alkali, aqua regia, strong oxidant and reducing agent have strong corrosive properties |

| D341F4-10 | 1.6 | 2.4 | 1.5 | ~30-180 | |

| D341F4-10 | 1.0 | 1.5 | 1.1 | ~30-160 | |

| D341F46-16 | 1.6 | 2.4 | 1.5 | ~30-160 | |

Material of main parts

| model | Part name | Material Science | Valve plate | Valve stem | Seal retainer ring | Lining | Worm gear |

| D341F4-10/16 | Material Science | Carbon steel lined polytetrafluoroethylene (F4) | Carbon steel lined polytetrafluoroethylene (F4) | 20Cr13 | Polytetrafluoroethylene propylene (F4) | silicon rubber | Cast iron, ductile iron |

| D341F46-10/16 | Carbon steel lined PTFE (F46) | Carbon steel lined PTFE (F46) |

Main overall connection dimensions

| DN | L | H1 | H | A | B | PN6 | PN10 | PN16 | |||||||||

| D | D1 | D2 | Z- d | D | D1 | D2 | Z- d | D | D1 | D2 | Z- d | ||||||

| 50 | 108 | 63 | 306 | 180 | 200 | 140 | 110 | 90 | 4-14 | 165 | 125 | 102 | 4-18 | 165 | 125 | 102 | 4-18 |

| 65 | 112 | 70 | 321 | 180 | 200 | 160 | 130 | 110 | 4-14 | 185 | 145 | 122 | 8-18 | 185 | 145 | 122 | 8-18 |

| 80 | 114 | 83 | 346 | 180 | 200 | 190 | 150 | 128 | 4-18 | 200 | 160 | 138 | 8-18 | 200 | 160 | 138 | 8-18 |

| 100 | 127 | 105 | 387 | 180 | 200 | 210 | 170 | 148 | 4-18 | 220 | 180 | 158 | 8-18 | 220 | 180 | 158 | 8-18 |

| 125 | 140 | 115 | 411 | 180 | 200 | 240 | 200 | 178 | 8-18 | 250 | 210 | 188 | 8-18 | 250 | 210 | 188 | 8-18 |

| 150 | 140 | 137 | 447 | 270 | 280 | 265 | 225 | 202 | 8-18 | 285 | 240 | 212 | 8-22 | 285 | 240 | 212 | 12-22 |

| 200 | 152 | 164 | 572 | 270 | 280 | 320 | 280 | 258 | 8-18 | 340 | 295 | 268 | 12-22 | 340 | 295 | 268 | 12-26 |

| 250 | 250 | 206 | 646 | 270 | 280 | 375 | 335 | 312 | 12-18 | 395 | 350 | 320 | 12-22 | 405 | 355 | 320 | 12-26 |

| 300 | 270 | 230 | 738 | 380 | 420 | 440 | 395 | 365 | 12-22 | 445 | 400 | 370 | 16-22 | 460 | 410 | 378 | 16-26 |

| 350 | 290 | 248 | 761 | 380 | 420 | 490 | 445 | 415 | 16-22 | 505 | 460 | 430 | 16-26 | 520 | 470 | 428 | 16-30 |

| 400 | 310 | 289 | 877 | 450 | 470 | 540 | 495 | 465 | 16-22 | 565 | 515 | 482 | 20-26 | 580 | 525 | 490 | 20-30 |

| 450 | 330 | 320 | 938 | 480 | 490 | 595 | 550 | 520 | 20-22 | 615 | 565 | 532 | 20-26 | 640 | 585 | 550 | 20-33 |

| 500 | 350 | 343 | 993 | 480 | 490 | 645 | 600 | 570 | 20-26 | 670 | 620 | 585 | 20-30 | 715 | 650 | 610 | 20-36 |

| 600 | 390 | 413 | 1131 | 480 | 490 | 755 | 705 | 670 | 24-26 | 780 | 725 | 685 | 24-30 | 840 | 770 | 725 | 24-36 |

| 700 | 430 | 478 | 1476 | 640 | 660 | 860 | 810 | 775 | 24-30 | 895 | 840 | 800 | 24–33 | 910 | 840 | 795 | 24-39 |

| 800 | 470 | 525 | 1533 | 640 | 660 | 975 | 920 | 880 | 24-30 | 1015 | 950 | 905 | 24-33 | 1025 | 950 | 900 | 24-39 |

| 900 | 510 | 585 | 1655 | 750 | 860 | 1075 | 1020 | 980 | 24-30 | 1115 | 1050 | 1005 | 28-33 | 1125 | 1050 | 1000 | 28-39 |

| 1000 | 550 | 640 | 1765 | 850 | 900 | 1175 | 1120 | 1080 | 28-30 | 1230 | 1160 | 1110 | 28-36 | 1255 | 1170 | 1115 | 28-42 |

Send your message to us:

-

Wholesale OEM/ODM China Sanitary Valve Stainles...

-

China Gold Supplier for China Factory Customize...

-

2019 New Style China SS316 Spring Loaded Double...

-

Chinese wholesale China Qingdao Eccentric Typ...

-

China Cheap price China Pn10 GB/API 6D/ANSI Oil...

-

Original Factory China High Quality JIS Standar...