We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for Fast delivery China 4A Handwheel Full Bore OS&Y Flanged Globe Valve, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us.

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for China Rising Stem Globe Valve, Din Globe Valve, We have been your reliable partner in international markets with the best quality solutions. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade items in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

Features of forged steel thread / socket welding globe valve

�

1. It has compact structure, beautiful appearance and reduced flow channel. Structural features: B.B. or W.B;

2. The sealing surface is made of alloy steel or cemented carbide. The matching of sealing materials is reasonable and the service life is long;

3. The valve disc is conical, and the valve stem is provided with inverted seal, with good sealing performance. The surface of the valve stem is nitrided, which has good corrosion resistance and friction resistance. The packing adopts flexible graphite, with reliable sealing, flexible operation and small opening and closing torque;

4. Various piping standards and connection forms (such as socket welding, butt welding and threaded connection) can be selected.

Executive standard for forged steel thread / socket welding globe valve

| Product specification | design code | Structural length | Connecting flange | Test and inspection | Pressure temperature |

| JB/T7746 | JB/T7746 | JB/T 79¡¢GB/T9113¡¢HG/T20592¡¢EN1092¡¢ASME B16.5 | GB/T26480GB/T13927¡¢API598 | GB/T12224JB/T7746 |

Main performance specifications

| Nominal pressure | Test items | strength test | Sealing test | Air seal test | Applicable temperature¡æ | Applicable medium |

| 1.6 | 2.4 | 1.76 | 0.6 | ¡Ü425 | Water, oilSteam and nitric acid | |

| 2.5 | 3.8 | 2.76 | ||||

| 4.0 | 6.0 | 4.4 | ||||

| 6.4 | 9.6 | 7.04 | ||||

| 10.0 | 15.0 | 11.0 | ||||

| 16.0 | 24.0 | 17.0 | ||||

Material of main parts of forged steel thread / socket welding globe valve

| Part name | Material of parts | |

| Body / bonnet | A105 | 1Cr18Ni9Ti |

| Disc / seat | 20Cr13 | 1Cr18Ni9Ti |

| Stem | 20Cr13 | 1Cr18Ni9Ti |

| seal ring | 1Cr13+HF | 1Cr18Ni9Ti+STL |

| filler | NBR/FPM Flexible graphite | teflon£¨PTFE£© |

| shim | Flexible graphite | |

| Bolt | 35/35CrMo | 1Cr18Ni9Ti |

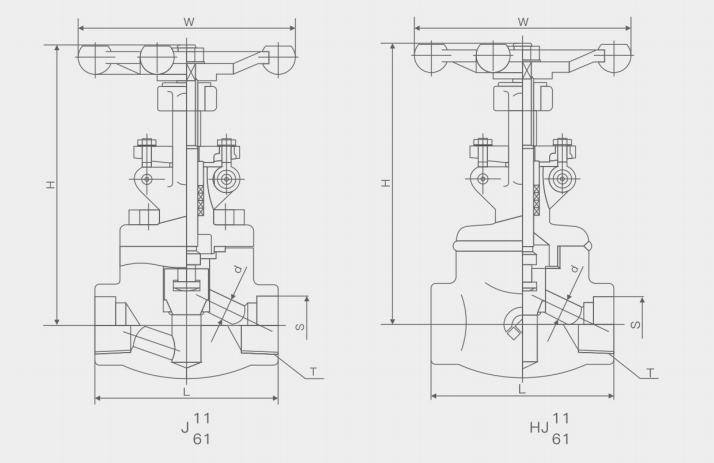

Drawing of forged steel thread socket welding stop valve

Application specification

1. Design and manufacture: ASME / ANSI B16.34; API 602; JB / t7746

2. Connection end size:

(1) Socket welding end: ASME / ANSI B16.11; JB / t1751

(2) Threaded end: ASME / ANSI b1.20.1 (NPT) GB / t7306 — 87 (RC)

3. Structural features: B.B or W.B; OS & Y

4. Main materials: A105; LF2; F5; F11; F22; f304; F316; f304l; f316l

5. Valve inspection and test: API598; GB / t26480; GB / t13927

Main connecting dimensions of forged steel thread / socket welding globe valve

| DN(mm) | R.P | 8 | 10 | 15 | 20 | 25 | 32 | 40 | 50 | - |

| NPS(in) | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | - | |

| DN(mm) | F.P | - | 8 | 10 | 15 | 20 | 25 | 32 | 40 | 50 |

| NPS(in) | - | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | |

| d | R.P | 7 | 10 | 10 | 13 | 19 | 24 | 29 | 36.5 | - |

| F.P | - | 7 | 10 | 13 | 18 | 24 | 29 | 36.5 | 46.5 | |

| L | R.P | 79 | 79 | 79 | 92 | 111 | 120 | 152 | 172 | - |

| F.P | - | 79 | 79 | 92 | 111 | 120 | 152 | 172 | 200 | |

| H(¿ªÆô) | R.P | 153 | 153 | 158 | 163 | 193 | 250 | 250 | 291 | - |

| F.P | - | 153 | 158 | 163 | 193 | 250 | 250 | 291 | 350 | |

| W | R.P | 100 | 100 | 100 | 100 | 125 | 160 | 160 | 180 | - |

| F.P | - | 100 | 100 | 100 | 125 | 160 | 160 | 180 | 240 | |

| WT(kg) | R.P | 1.9 | 1.8 | 1.7 | 2.1 | 3.3 | 7.5 | 7.5 | 11.4 | - |

| F.P | - | 2.1 | 1.9 | 2.3 | 3.6 | 7.8 | 8.2 | 12.0 | 15.0 |

Send your message to us:

-

New Delivery for China Low Resistance Deshpot C...

-

Wholesale Price China Manufacturer 6 Inch Groov...

-

China Manufacturer for China Body Wafer Type Si...

-

Top Grade China JIS 10K Cast Steel Globe Valve ...

-

Factory best selling China API Metal Seat Seal ...

-

Manufacturing Companies for China ANSI Female T...