ComInstallation and Maintenance: Chinese Standard Flange Globe Valve Operation Manual

ComInstallation and Maintenance: Chinese Standard Flange Globe Valve Operation Manual

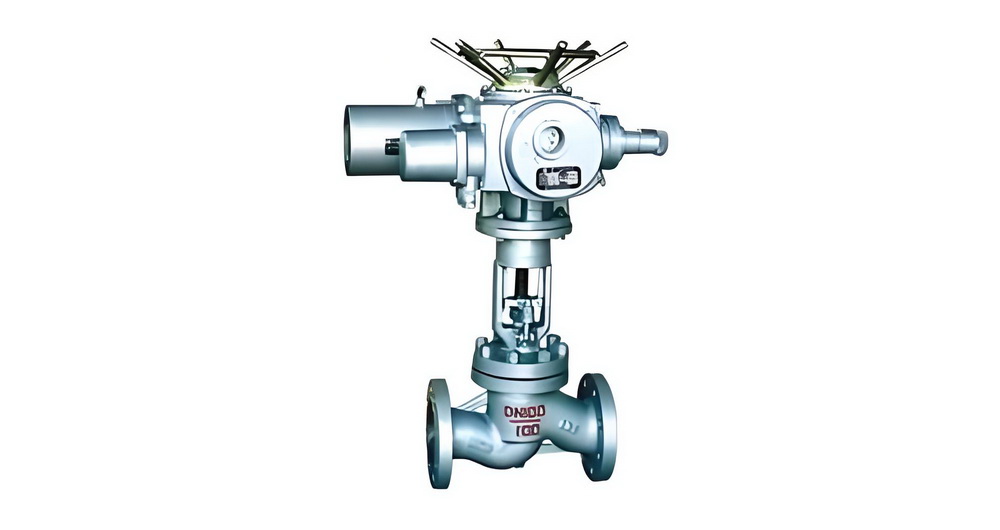

1、 Introduction

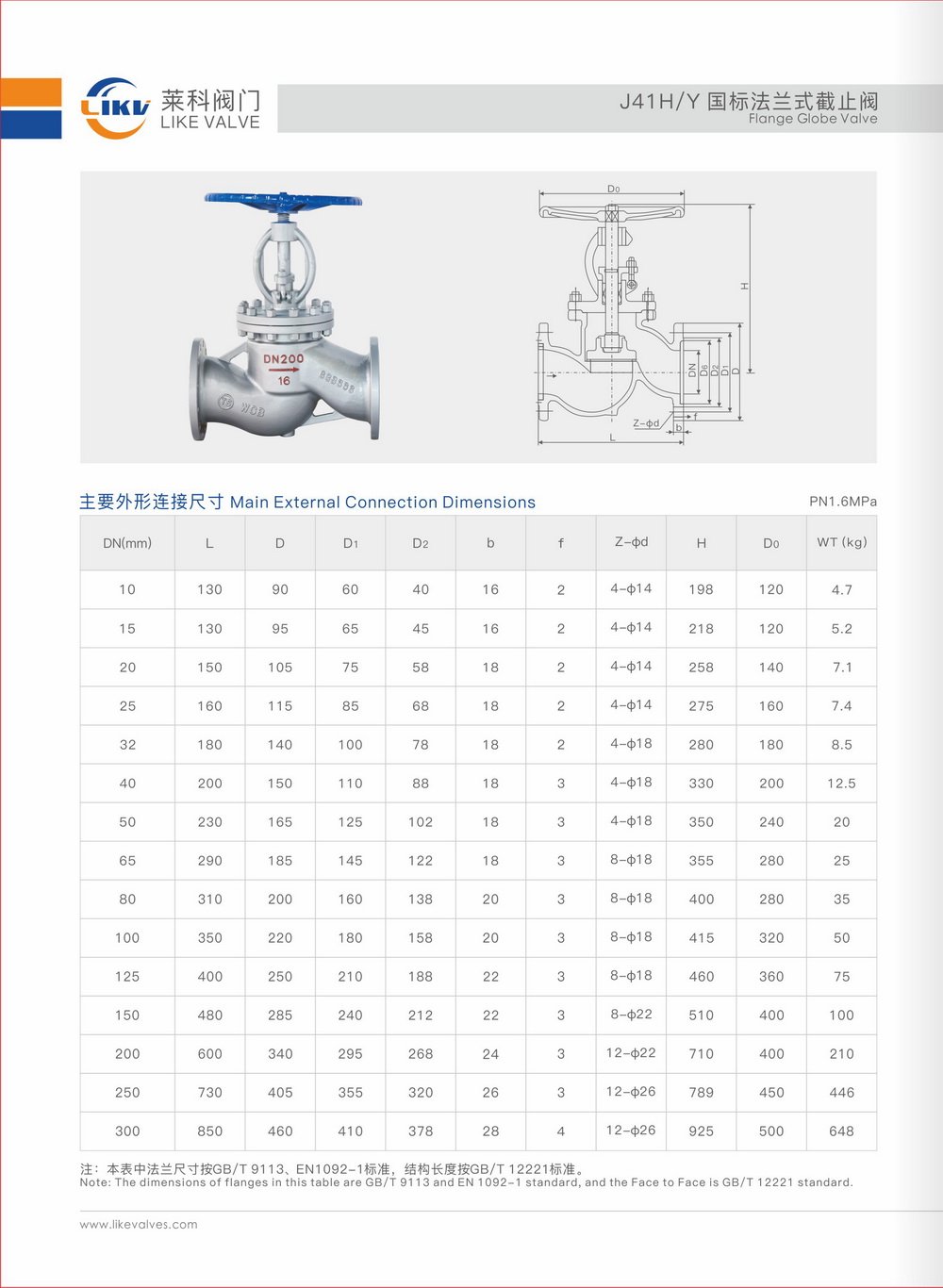

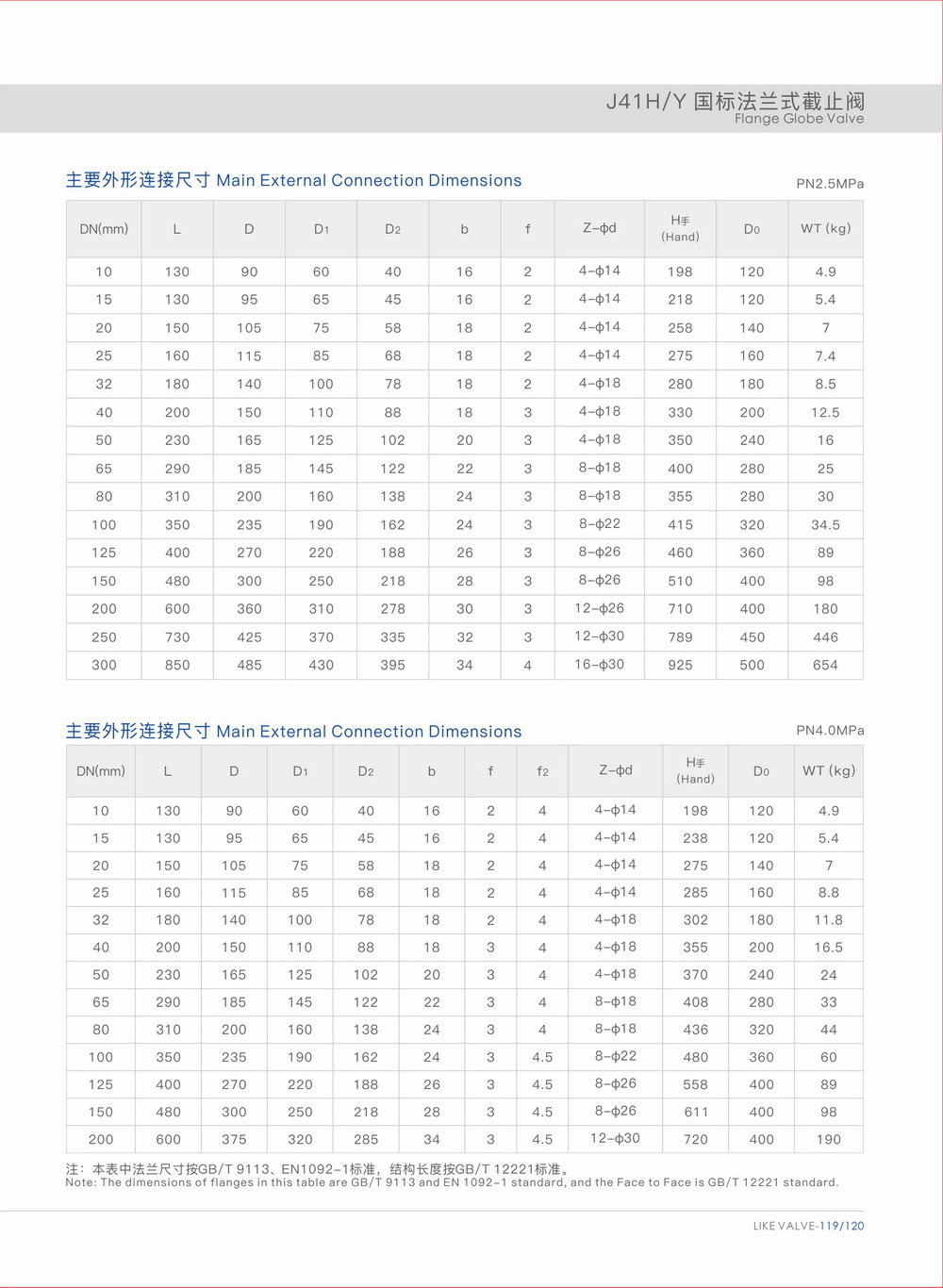

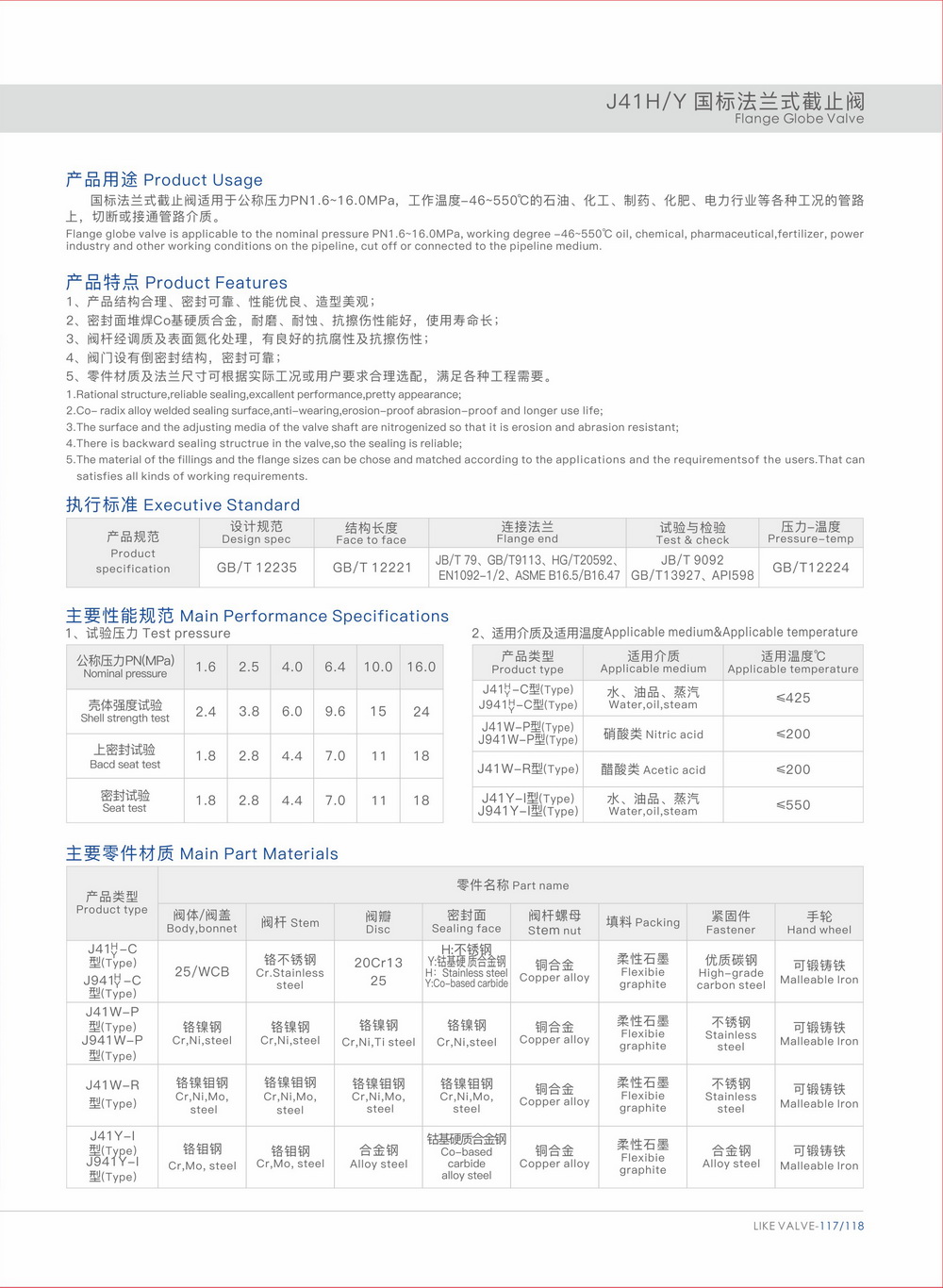

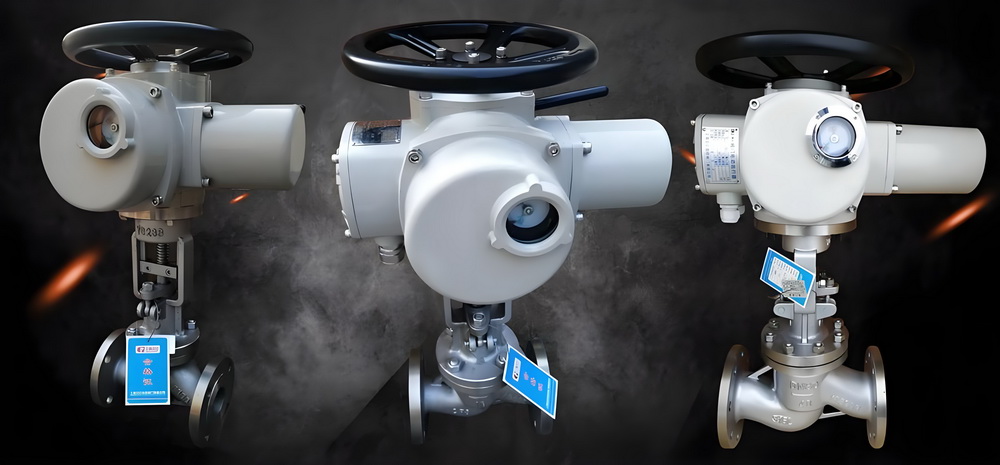

As a key component in industrial fluid control systems, the correct installation and maintenance of Chinese standard flange globe valves are crucial for ensuring stable system operation. This manual aims to provide detailed installation and maintenance guidelines for relevant operators to ensure the safe and effective use of valves.

2、 Installation steps

Determine installation location: Determine the installation location of the shut-off valve based on system requirements. Ensure that the valve can be easily operated and maintained, while considering the requirements of fluid flow direction and pipeline layout.

Prepare installation tools and materials: Prepare necessary installation tools and materials such as wrenches, screws, nuts, sealing gaskets, etc.

Fluid shutdown: Before installation, make sure to close the relevant fluid pipelines to avoid fluid leakage or splashing during the installation process.

Connecting pipeline: Use a flange to connect the shut-off valve to the pipeline, ensuring that the flange sealing surface is clean and undamaged. Use a wrench and nut to tighten the flange, ensuring even tightening force to avoid flange deformation or leakage.

Check installation quality: After installation is completed, open the fluid source and check if there is any leakage in the valve. Ensure that the valve can open and close normally, and operate flexibly without jamming.

3、 Maintenance points

Regular inspection: Regularly inspect the globe valve, including its appearance, sealing performance, and operational flexibility. If any abnormalities or damages are found, they should be dealt with or replaced in a timely manner.

Cleaning and maintenance: Regularly clean the valve to remove surface dirt and impurities. Be careful not to use corrosive cleaning agents during the cleaning process.

Lubrication of operating components: Regularly lubricate the operating components of the valve to reduce friction and wear. Use appropriate lubricating oil or grease and lubricate according to the operating requirements.

Long term storage treatment: If the valve needs to be stored for a long time, the valve should be closed and the flange connection should be removed to discharge the residual pressure in the pipeline. Clean and lubricate the valve, and package it with protective materials to prevent corrosion and damage.

4、 Precautions

Follow operating procedures: During installation and maintenance, it is essential to follow relevant operating procedures and safety requirements to ensure personnel safety and equipment stability.

Use appropriate tools: Use appropriate tools for installation and maintenance operations to avoid equipment damage or personal injury caused by improper use.

Pay attention to sealing performance: During installation and maintenance, special attention should be paid to the sealing performance of the valve to ensure no leakage occurs.

5、 Conclusion

This manual provides installation and maintenance guidelines for Chinese standard flange globe valves, aimed at helping operators use and maintain valves correctly and safely. In the actual operation process, flexible application should be carried out according to specific situations and actual needs, and relevant safety regulations and operating procedures should be followed. By proper installation and maintenance, the stable operation and long-term service life of Chinese standard flange globe valves can be ensured.

Please note that this manual is for general guidance only, and specific operations should be carried out in conjunction with the actual situation and the user manual provided by the manufacturer. For special circumstances or difficult issues, it is recommended to consult professional engineers or manufacturer technical support.