We constantly execute our spirit of ”Innovation bringing progress, Highly-quality making sure subsistence, Administration advertising advantage, Credit rating attracting consumers for OEM Customized Direct Sales Pn20 Manual Butterfly Valves, We warmly welcome your participation based on mutual benefits in the near future.

We constantly execute our spirit of ”Innovation bringing progress, Highly-quality making sure subsistence, Administration advertising advantage, Credit rating attracting consumers for Butterfly Valve, Direct Sales Butterfly Valve, Pn20 Manual Butterfly Valves, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal solutions. In his way, We can enrich our life style and promote a better living environment for the global community.

Product characteristics

1. The valve body adopts split type, which makes it easy to replace parts on site. Epoxy coating is used on the surface, which has anti-corrosion and wear resistance. It has good resistance in salt solution, grease, alcohol, petroleum, weak acid and alkali and humid environment.

2. The key to seal is the valve seat. We choose a reasonable structure – trench type, with silicone rubber gasket at the base of the seat to regulate the sealing performance of the valve. In a reasonable pressure ratio, the valve can be in the prescribed pressure range without any leakage. Complete air tightness is achieved, and no visible leakage is observed in the barometric test.

3. The PTFE lined valve plate with spherical sealing surface is adopted.

4. Small size, light weight, small torque and easy operation. Long life, tens of thousands of open and close tests are intact.

5. It has excellent cutting performance, called durability, and has both regulation. It can be used to cut off or adjust the flow rate quickly.

6. Multifunction

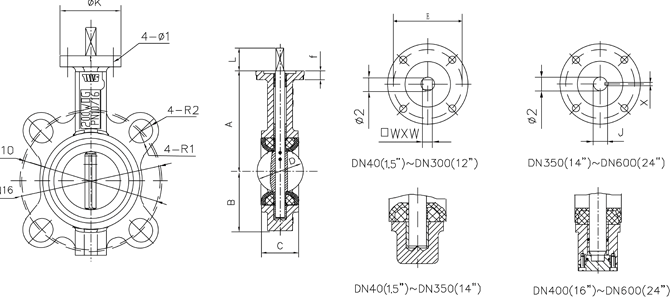

Design drawings

Performance specification

|

Nominal diameter |

50(2″) ~1000 (40″) |

50(2″) ~800 (32″) |

|

|

Nominal pressure |

1.0 |

1.6 |

|

|

Test pressure |

housing |

1.5 |

2.4 |

|

Seal up |

1.1 |

1.76 |

|

|

Applicable temperature |

-15~+150 |

||

|

Applicable medium |

Freshwater, sewage, seawater, air, steam, food, medicine, various oils, acids, alkalis, salts, etc. |

||

Major Dimensions and Weights

| DN | A | B | C | D | L | H | D1 | n-ø | K | E | n1-ø1 | ø2 | G | 重量 | |

| mm | inch | ||||||||||||||

| 50 | 2″ | 161 | 80 | 42 | 52.9 | 32 | 84.84 | 120 | 4-ø23 | 77 | 57.15 | 4-ø6.7 | 12.6 | 118 | 2.5 |

| 65 | 2.5″ | 175 | 89 | 44.7 | 64.5 | 32 | 96.2 | 136.2 | 4-ø26.5 | 77 | 57.15 | 4-ø6.7 | 12.6 | 137 | 3.2 |

| 80 | 3″ | 181 | 95 | 45.2 | 78.8 | 32 | 61.23 | 160 | 8-ø18 | 77 | 57.15 | 4-ø6.7 | 12.6 | 143 | 3.6 |

| 100 | 4″ | 200 | 114 | 52.1 | 104 | 32 | 70.80 | 185 | 4-ø24.5 | 92 | 69.85 | 4-ø10.3 | 15.77 | 156 | 4.9 |

| 125 | 5″ | 213 | 127 | 54.4 | 123.3 | 32 | 82.28 | 215 | 4-ø23 | 92 | 69.85 | 4-ø10.3 | 18.92 | 190 | 7 |

| 150 | 6″ | 226 | 139 | 55.8 | 155.6 | 32 | 91.08 | 238 | 4-ø25 | 92 | 69.85 | 4-ø10.3 | 18.92 | 212 | 7.8 |

| 200 | 8″ | 260 | 175 | 60.6 | 202.5 | 45 | 112.89/76.35 | 295 | 4-ø25/4-ø23 | 115 | 88.9 | 4-ø14.3 | 22.1 | 268 | 13.2 |

| 250 | 10″ | 292 | 203 | 65.6 | 250.5 | 45 | 92.40 | 357 | 4-ø29 | 115 | 88.9 | 4-ø14.3 | 28.45 | 325 | 19.2 |

| 300 | 12″ | 337 | 242 | 76.9 | 301.6 | 45 | 105.34 | 407 | 4-ø29 | 140 | 107.95 | 4-ø14.3 | 31.6 | 403 | 32.5 |

| 350 | 14″ | 368 | 267 | 76.5 | 333.3 | 45 | 91.11 | 467 | 4-ø30 | 140 | 107.95 | 4-ø14.3 | 31.6 | 436 | 41.3 |

| 400 | 16″ | 400 | 309 | 86.5 | 389.6 | 51.2/72 | 100.47/102.42 | 515/525 | 4-ø26/4-ø30 | 197 | 158.75 | 4-ø20.6 | 33.15 | 488 | 61 |

| 450 | 18″ | 422 | 328 | 105.6 | 440.51 | 51.2/72 | 88.39/91.51 | 565/585 | 4-ø26/4-ø30 | 197 | 158.75 | 4-ø20.6 | 38 | 539 | 79 |

| 500 | 20″ | 480 | 361 | 131.8 | 491.6 | 64.2/82 | 96.99/101.68 | 620/650 | 4-ø26/4-ø33 | 197 | 158.75 | 4-ø20.6 | 41.15 | 593 | 128 |

| 600 | 24″ | 562 | 459 | 152 | 592.5 | 70.2/82 | 113.42/120.46 | 725/770 | 20-ø30/20-ø36 | 276 | 215.9 | 4-ø22.2 | 50.65 | 816 | 188 |

| 700 | 28″ | 624 | 520 | 163 | 695 | 66/82 | 109.65 | 840 | 24-ø30/20-ø36 | 300 | 254 | 8-ø18 | 55/63.35 | 895 | 284 |

| 800 | 32″ | 672 | 591 | 188 | 794.7 | 66/82 | 124 | 950 | 24-ø33/24-ø39 | 300 | 254 | 8-ø18 | 55/63.35 | 1015 | 368 |

| 900 | 36″ | 720 | 656 | 203 | 864.7 | 118 | 117.57 | 1050 | 24-ø33 | 300 | 254 | 8-ø18 | 75 | 1115 | 713 |

| 1000 | 40″ | 800 | 721 | 216 | 965 | 142 | 129.89 | 1160 | 24-ø36 | 300 | 254 | 8-ø18 | 85 | 1230 | 864 |