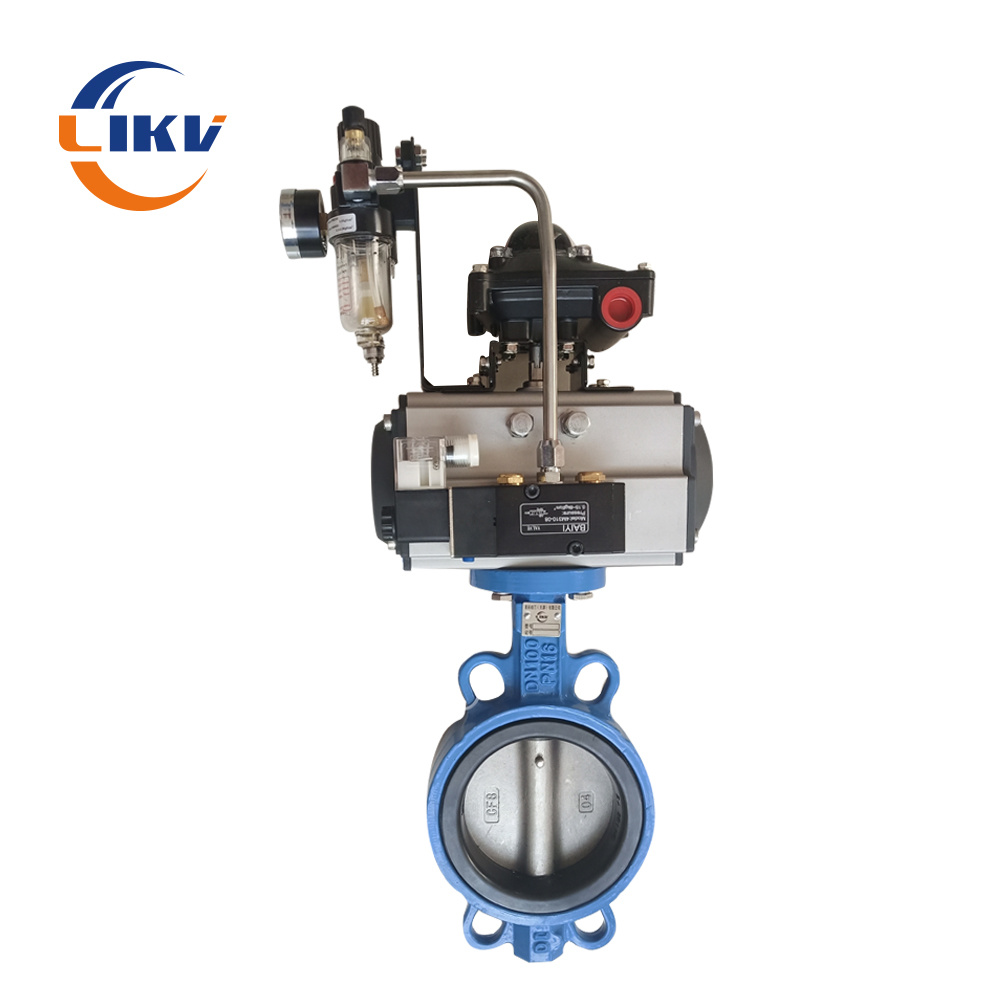

Advantages of a Pneumaict Butterfly Valve

1, compact and lightweight, easy to install and repair.

2, the structure is simple, compact

3, good adjustment performance.

4, Non internal leak.

5, open and close more than 50 thousand times still keep zero leakage.

6, sealing parts can be replaced, and sealed to achieve a two-way seal.

7, the butterfly plate can be based on user requirements of coating, such as nylon or ptfe.

8, the valve can be designed to connect to the flange and the clip connection.

9, the Power can choose , electric or pneumatic.

Pneumatic actuators contain three joint accessories . What is three joint accessories

In the pneumatic transmission system, the pneumatic three joint accessories refers to the air filter, the pressure reducing valve and the oil mist. Some brands of solenoid valves and cylinders can achieve oil-free lubrication (lubrication function by grease), so there is no need to use the oil mist! Generally, the filtration degree is 50-75¦Ìm, the pressure regulating range is 0.5-10Mpa, if the filtering accuracy is 5-10¦Ìm, 10-20¦Ìm, 25-40¦Ìm, and the pressure regulating is 0.05-0.3Mpa, 0.05-1Mpa. The three components without pipe connection are called triples. Three large components are indispensable air source devices in most pneumatic systems. Installed near the gas equipment, they are the best guarantee of compressed air quality. The installation sequence of the three large parts according to the intake direction are respectively air filter, pressure reducing valve and oil mist. The combination of air filter and pressure reducing valve can be called pneumatic dual. The air filter and pressure reducing valve can also be assembled together to become a filter pressure reducing valve (function and air filter and pressure reducing valve combined to use the same). In some cases, oil mist cannot be allowed in the compressed air, so it is necessary to use oil mist separator to filter out the oil mist in the compressed air. In short, these components can be selected according to the need, and they can be combined to use.

The air filter is used to clean the air source. It can filter the water in the compressed air to avoid the water entering the device with the gas.

The pressure reducing valve can regulate the pressure of the air source, so that the air source is in a constant state, which can reduce the damage to the valve or actuator and other hardware when the air pressure changes. The filter is used to clean the air source. It can filter the water in the compressed air and avoid the water entering the device with the gas.

Oil mist can lubricate the moving parts of the body, and can lubricate the parts that are not convenient to add lubricating oil, greatly extending the service life of the body.

|

Product� Name

|

Pneumatic Actuator Wafer Butterfly Valve Manufacturers

|

||

|

Size (mm)

|

50-2000mm

|

||

|

Flange connection standard selection

|

EN1092 PN10,PN16;

ASME 125LB,150LB; JIS10K; Universal |

||

|

�

�

�

�

Material |

Body/Shell

|

GGG40/50; WCB; CF8; CF8M; 2205; 2507; Al-bronze

|

|

|

Disc

|

GGG40/50; CF8; CF8M; 2205; 2507; 1.4529; Al-bronze;

Rubber coated; PTFE lined; Nylon coated; Halar coated

|

||

|

Stem/shaft

|

SS410/420/416; SS431; SS304; Monel

|

||

|

Seat material and suitable Temp.

|

EPDM

|

-10¡æ ~ +80¡æ

|

|

|

NBR

|

-10¡æ ~ +80¡æ

|

||

|

Vaiton

|

-10¡æ ~ +180¡æ

|

||

|

Heat resistant EPDM

|

-10¡æ ~ +120¡æ

|

||

|

PTFE

|

-10¡æ ~ +150¡æ

|

||

|

Operating selection

|

Lever handle; wormgear; Electric actuator; Pneumatic actuator; Hydraulic actuator

|

||

Products Detailes

Certificates

Process

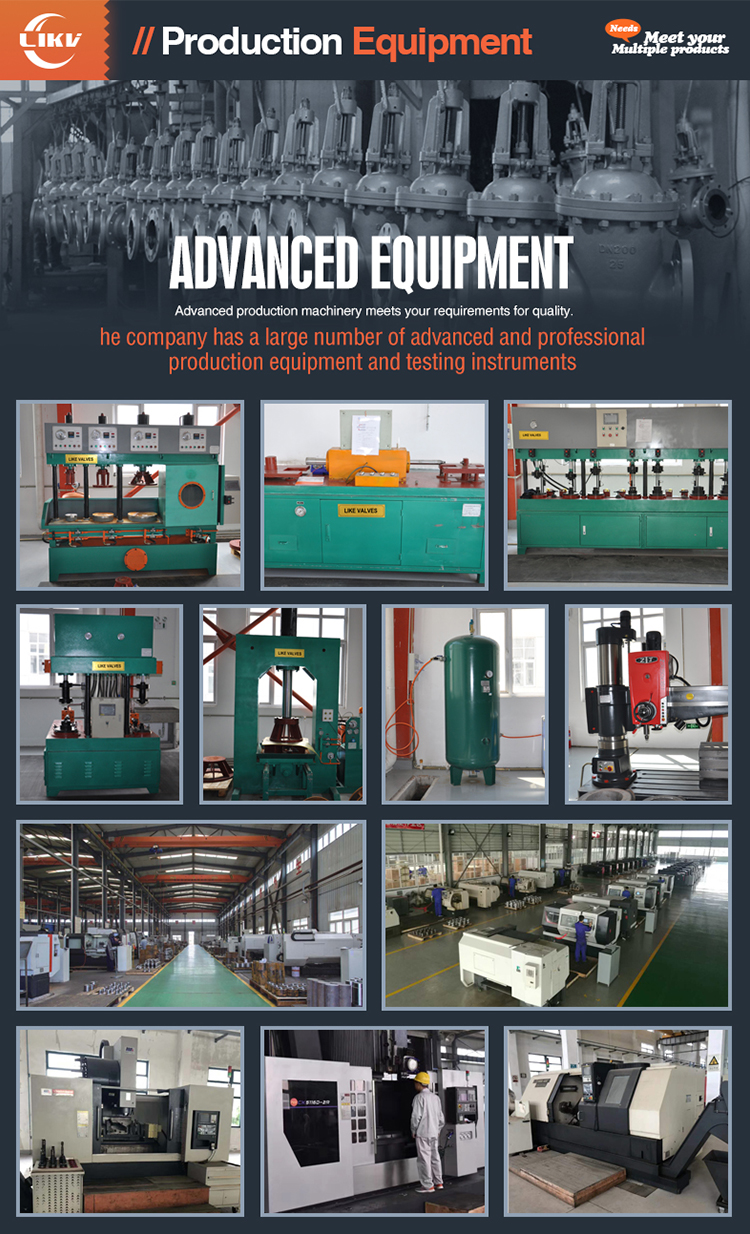

Equipments

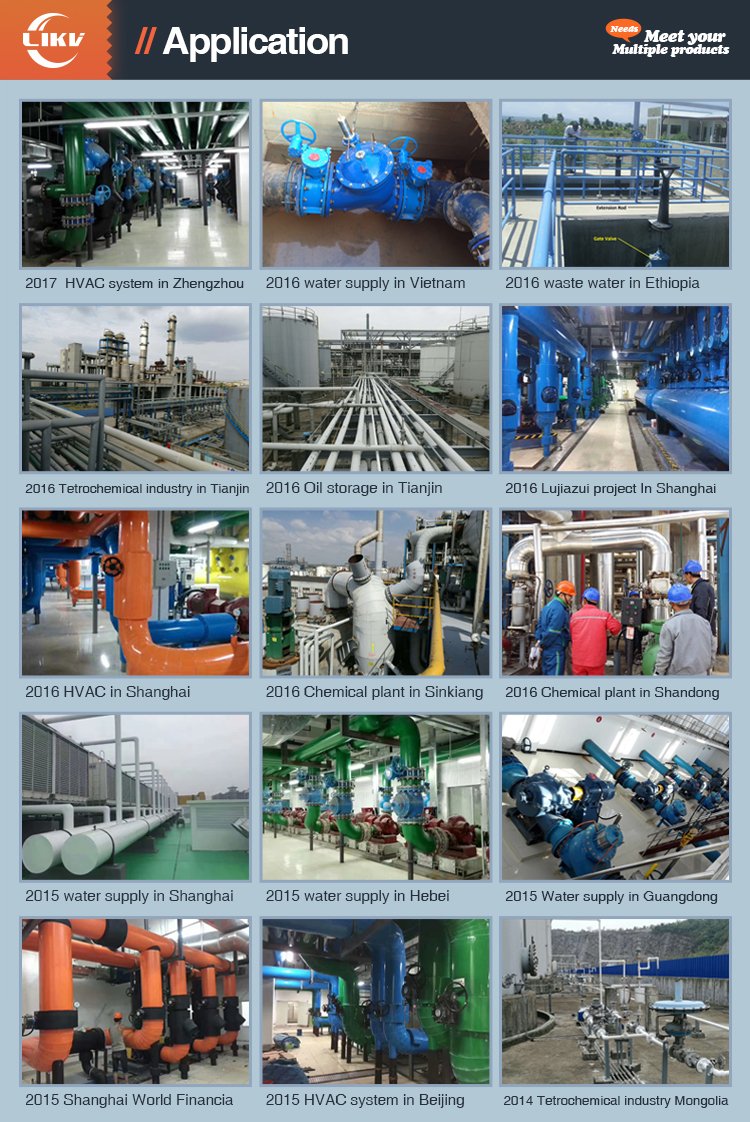

Application