Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for Special Design for China Industrial Flange or Bw Ends Cast Iron & Forged Stainless Steel Globe Valve, With a wide range, top quality, sensible price ranges and stylish designs,Our merchandise are widely recognized and dependable by users and can meet up with continuously changing economic and social needs.

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for China Globe Valve, Pressure Seal Globe Valve, To work with an excellent items manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

Features of J41H / y flange globe valve

1. The product has reasonable structure, reliable sealing, excellent performance and beautiful appearance;

2. The sealing surface overlaid with Co based cemented carbide has good wear resistance, corrosion resistance, abrasion resistance and long service life;

3. The valve stem has good corrosion resistance and scratch resistance after quenching and tempering and surface nitriding treatment;

4. The valve is equipped with reverse sealing structure, which is reliable;

5. Parts material and flange size can be reasonably selected according to actual working conditions or user requirements to meet various engineering needs.

Executive standard

| Product specification | design code | Structural length | Connecting flange | Test and inspection | Pressure temperature |

| GB/T 12235 | GB/T 12221 | JB/T 79、GB/T9113、HG/T20592、EN1092-1/2、ASME B16.5/B16.47 | JB/T 9092GB/T13927、API598 | GB/T12224 |

Main performance specification of J41H / Y flange globe valve

1. Test pressure

| Nominal pressure PN(MPa) | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 16.0 |

| Shell strength test | 2.4 | 3.8 | 6.0 | 9.6 | 15 | 24 |

| Upper seal test | 1.8 | 2.8 | 4.4 | 7.0 | 11 | 18 |

| Sealing test | 1.8 | 2.8 | 4.4 | 7.0 | 11 | 18 |

2. Applicable medium and temperature

| product type | Applicable medium | Applicable temperature ℃ |

| J41H/Y-C、J941H/Y-C | Water, oil, steam | ≤425 |

| J41W-P、J941W-P | Nitric acids | ≤200 |

| J41W-R | Acetic acids | ≤200 |

| J41Y-I、J941Y-I | Water, oil, steam | ≤550 |

Material of main parts

| product type | Part name | |||||||

| Body / bonnet | Stem | Valve disc | Sealing surface | Stem nut | filler | a fastening | handwheel | |

| J41H/Y-C/J941H/Y-C | 25/WCB | Chromium stainless steel | 20Cr1325 | H:Stainless steel Y: cobalt based cemented carbide steel | copper alloy | Flexible graphite | High quality carbon steel | malleable iron |

| J41W-P/J941W-P | Chromium nickel steel | Chromium nickel steel | Chromium nickel steel | Chromium nickel steel | copper alloy | Flexible graphite | stainless steel | malleable iron |

| J41W-R | Cr Ni Mo steel | Cr Ni Mo steel | Cr Ni Mo steel | Cr Ni Mo steel | copper alloy | Flexible graphite | stainless steel | malleable iron |

| J41Y-I/J941Y-I | Chromium molybdenum steel | Chromium molybdenum steel | copper alloy | Cobalt based cemented carbide steel | copper alloy | Flexible graphite | Alloy steel | malleable iron |

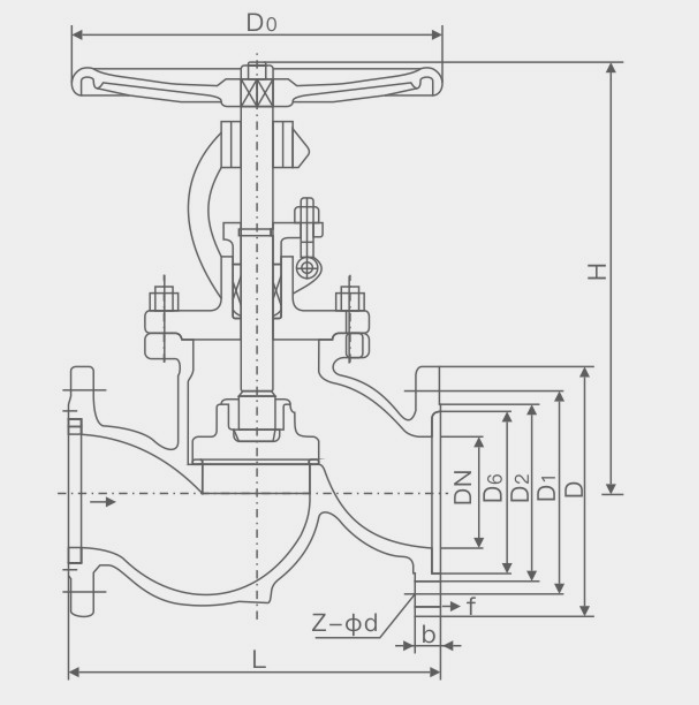

J41H/Y Drawing of national standard flange globe valve

J41H/Y National standard flange stop valve PN1.6MPa main connecting dimensions

| DN(mm) | L | D | D1 | D2 | b | f | Z-Φd | H | D0 | WT(kg) |

| 10 | 130 | 90 | 60 | 40 | 16 | 2 | 4-Φ14 | 198 | 120 | 4.7 |

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | 218 | 120 | 5.2 |

| 20 | 150 | 105 | 75 | 58 | 18 | 2 | 4-Φ14 | 258 | 140 | 7.1 |

| 25 | 160 | 115 | 85 | 68 | 18 | 2 | 4-Φ14 | 275 | 160 | 7.4 |

| 32 | 180 | 140 | 100 | 78 | 18 | 2 | 4-Φ18 | 280 | 180 | 8.5 |

| 40 | 200 | 150 | 110 | 88 | 18 | 3 | 4-Φ18 | 330 | 200 | 12.5 |

| 50 | 230 | 165 | 125 | 102 | 18 | 3 | 4-Φ18 | 350 | 240 | 20 |

| 65 | 290 | 185 | 145 | 122 | 18 | 3 | 8-Φ18 | 355 | 280 | 25 |

| 80 | 310 | 200 | 160 | 138 | 20 | 3 | 8-Φ18 | 400 | 280 | 35 |

| 100 | 350 | 220 | 180 | 158 | 20 | 3 | 8-Φ18 | 415 | 320 | 50 |

| 125 | 400 | 250 | 210 | 188 | 22 | 3 | 8-Φ18 | 460 | 360 | 75 |

| 150 | 480 | 285 | 240 | 212 | 22 | 3 | 8-Φ22 | 510 | 400 | 100 |

| 200 | 600 | 340 | 295 | 268 | 24 | 3 | 12-Φ22 | 710 | 400 | 210 |

| 250 | 730 | 405 | 355 | 320 | 26 | 3 | 12-Φ26 | 789 | 450 | 446 |

| 300 | 850 | 460 | 410 | 378 | 28 | 4 | 12-Φ26 | 925 | 500 | 648 |

J41H/Y National standard flange type stop valve PN2.5MPa main connection dimensions

| DN(mm) | L | D | D1 | D2 | b | f | Z-Φd | H | D0 | WT(kg) |

| 10 | 130 | 90 | 60 | 40 | 16 | 2 | 4-Φ14 | 198 | 120 | 4.9 |

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | 218 | 120 | 5.4 |

| 20 | 150 | 105 | 75 | 58 | 18 | 2 | 4-Φ14 | 258 | 140 | 7 |

| 25 | 160 | 115 | 85 | 68 | 18 | 2 | 4-Φ14 | 275 | 160 | 7.4 |

| 32 | 180 | 140 | 100 | 78 | 18 | 2 | 4-Φ18 | 280 | 180 | 8.5 |

| 40 | 200 | 150 | 110 | 88 | 18 | 3 | 4-Φ18 | 330 | 200 | 12.5 |

| 50 | 230 | 165 | 125 | 102 | 20 | 3 | 4-Φ18 | 350 | 240 | 16 |

| 65 | 290 | 185 | 145 | 122 | 22 | 3 | 8-Φ18 | 400 | 280 | 25 |

| 80 | 310 | 200 | 160 | 138 | 24 | 3 | 8-Φ18 | 355 | 280 | 30 |

| 100 | 350 | 235 | 190 | 162 | 24 | 3 | 8-Φ22 | 415 | 320 | 34.5 |

| 125 | 400 | 270 | 220 | 188 | 26 | 3 | 8-Φ26 | 460 | 360 | 89 |

| 150 | 480 | 300 | 250 | 218 | 28 | 3 | 8-Φ26 | 510 | 400 | 98 |

| 200 | 600 | 360 | 310 | 278 | 30 | 3 | 12-Φ26 | 710 | 400 | 180 |

| 250 | 730 | 425 | 370 | 335 | 32 | 3 | 12-Φ30 | 789 | 450 | 446 |

| 300 | 850 | 485 | 430 | 395 | 34 | 4 | 16-Φ30 | 925 | 500 | 654 |

J41H/Y Main dimensions of PN4.0MPa flange stop valve

| DN(mm) | L | D | D1 | D2 | b | f | f2 | Z-Φd | H | D0 | WT(kg) |

| 10 | 130 | 90 | 60 | 40 | 16 | 2 | 4 | 4-Φ14 | 198 | 120 | 4.9 |

| 15 | 13 | 95 | 65 | 45 | 16 | 2 | 4 | 4-Φ14 | 238 | 120 | 5.4 |

| 20 | 150 | 105 | 75 | 58 | 18 | 2 | 4 | 4-Φ14 | 275 | 140 | 7 |

| 25 | 160 | 115 | 85 | 68 | 18 | 2 | 4 | 4-Φ14 | 285 | 160 | 8.8 |

| 32 | 180 | 140 | 100 | 78 | 18 | 2 | 4 | 4-Φ18 | 302 | 180 | 11.8 |

| 40 | 200 | 150 | 110 | 88 | 18 | 3 | 4 | 4-Φ18 | 355 | 200 | 16.5 |

| 50 | 230 | 165 | 125 | 102 | 20 | 3 | 4 | 4-Φ18 | 370 | 240 | 24 |

| 65 | 290 | 185 | 145 | 122 | 22 | 3 | 4 | 8-Φ18 | 408 | 280 | 33 |

| 80 | 310 | 200 | 160 | 138 | 24 | 3 | 4 | 8-Φ18 | 436 | 320 | 44 |

| 100 | 350 | 235 | 190 | 162 | 24 | 3 | 4.5 | 8-Φ22 | 480 | 360 | 60 |

| 125 | 400 | 270 | 220 | 188 | 26 | 3 | 4.5 | 8-Φ26 | 558 | 400 | 89 |

| 150 | 480 | 300 | 250 | 218 | 28 | 3 | 4.5 | 8-Φ26 | 611 | 400 | 98 |

| 200 | 600 | 375 | 320 | 285 | 34 | 3 | 4.5 | 12-Φ30 | 720 | 400 | 190 |

Send your message to us:

-

Factory making China Cast Iron Flange End Foot ...

-

ODM Supplier China Casting Iron Wafer Butterfly...

-

Popular Design for China Cast Iron Ductile Iron...

-

Well-designed Industrial Stainless Steel Cast S...

-

High Quality for China Russian Standard GOST Pn...

-

Wholesale OEM/ODM China Carbon Steelss CF8m Cas...