Gaining purchaser gratification is our firm’s intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for 18 Years Factory China Stainless Steel Ss Flange Type Swing Check Valve, Our company quickly grew in size and reputation because of its absolute dedication to high quality manufacturing, high value of products and excellent customer service.

Gaining purchaser gratification is our firm’s intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for China Check Valve, Swing Check Valve, Our objective is “to supply first step goods and best service for our customers, thus we are sure you should have a margin benefit through cooperating with us”. If you are interested in any of our solutions or would like to discuss a custom order, be sure to feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.

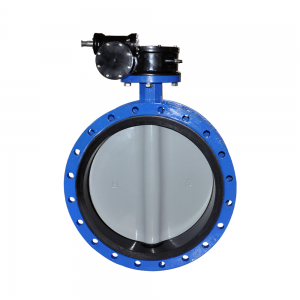

J44h / y angle flange globe valve details

Engineering diameter: DN 15 ~ DN 200

Nominal pressure: PN16 ~ 25

Working temperature: – 29 ¡æ ~ 425 ¡æ

Applicable media: water, steam, oil, nitric acid, boric acid, etc

Design criteria�

GB/T12235¡¢GB/T12233¡¢GB/T2492¡¢JB/T450¡¢ASME B16.34¡¢API 602¡¢BS 1873¡¢DIN 3356�

Main performance specifications

1. Test pressure

|

Nominal pressure £¨MPa£© |

Test pressure£¨MPa£© | |||

| housing | Sealing ( fluid ) | Seal (gas) | Upper seal | |

| 1.6 | 2.4 | 1.8 | 0.6 | 1.8 |

| 2.5 | 3.8 | 2.8 | 0.6 | 2.8 |

| 4.0 | 6.0 | 4.4 | 0.6 | 4.4 |

| 6.4 | 9.6 | 7.0 | 0.6 | 7.0 |

| 10.0 | 15.0 | 11.0 | 0.6 | 11.0 |

| 16.0 | 24.0 | 18.0 | 0.6 | 18.0 |

2. Scope of application

| Shell material | Applicable medium | Applicable temperature (¡æ) |

| Carbon steel (type C) | Water, steam, oil | ¡Ü425 |

| Cr Ni Ti steel (P type) | Nitric acids | ¡Ü200 |

| Cr Ni Ti steel (R type) | Acetic acids | ¡Ü200 |

| Chromium molybdenum steel (type I) | Water, steam, oil | ¡Ü550 |

Main connection dimensions

| DN(mm) | L | D | D1 | D2 | b | f | Z-¦µd | D0 | H1 | H2 |

| (J44H/Y/W – 16/25C/P/R/L) | ||||||||||

| 25 | 160 | 115 | 85 | 65 | 18 | 3 | 4-14 | 100 | 220 | 236 |

| 32 | 180 | 135 | 100 | 78 | 18 | 3 | 4-18 | 120 | 251 | 273 |

| 40 | 210 | 145 | 110 | 85 | 20 | 3 | 4-18 | 140 | 283 | 306 |

| 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-18 | 160 | 316 | 344 |

| 65 | 290 | 180 | 145 | 120 | 22 | 3 | 4-18 | 180 | 353 | 383 |

| 80 | 310 | 195 | 160 | 135 | 22 | 3 | 8-18 | 200 | 437 | 479 |

| 100 | 350 | 215 | 180 | 155 | 24 | 3 | 8-18 | 240 | 479 | 529 |

| 125 | 400 | 245 | 230 | 180 | 26 | 3 | 8-18 | 280 | 542 | 608 |

| 150 | 480 | 280 | 240 | 210 | 28 | 4 | 8-18 | 320 | 605 | 680 |

| 200 | 600 | 335 | 295 | 265 | 30 | 4 | 12-23 | 360 | 650 | 755 |

�