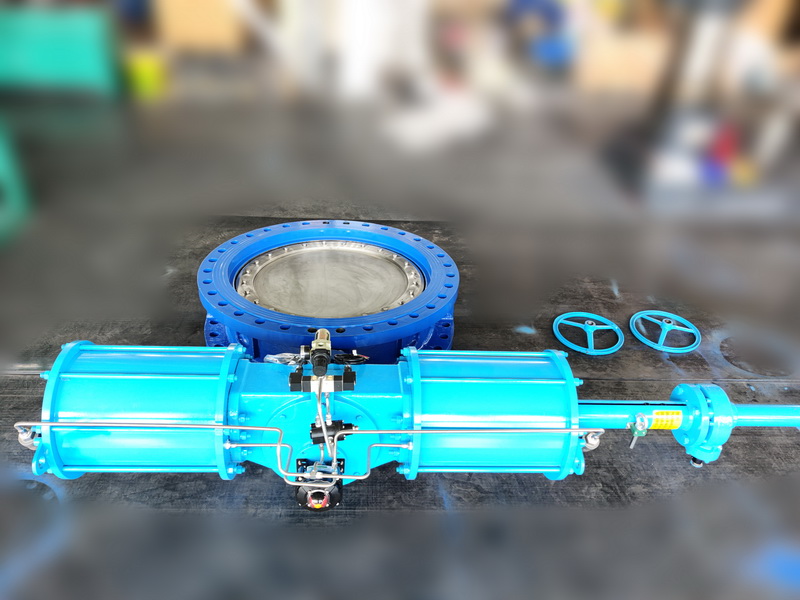

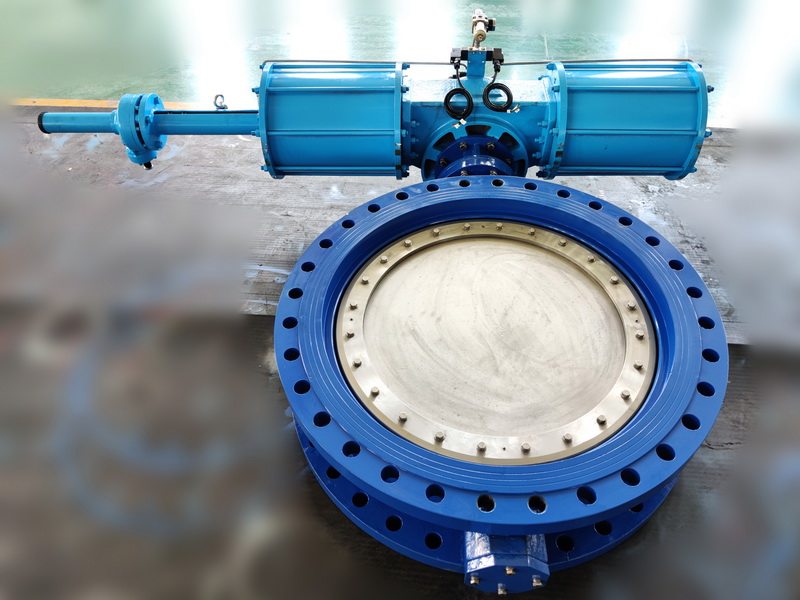

Product Name: Pneumatic Triple Eccentric Double Flange Butterfly Valve

Product features:

1. Compact structure, compact size, light weight, and convenient installation.

2. Adopting a three eccentric design, the friction is small when opening and closing, and the service life is long.

3. Adopting double flange connection, reliable sealing, suitable for high-pressure working conditions.

4. Adjustable valve opening, high flow control accuracy.

5. Made of high-quality materials with strong corrosion resistance, suitable for various media.

6. Widely used in automation control systems in industries such as chemical, petroleum, natural gas, metallurgy, and power.

Technical parameters:

1. Working pressure: 1.6-6.4MPa

2. Working temperature: -29-180 ℃

3. Applicable media: gas, liquid, steam, etc

4. Valve body material: cast iron, stainless steel, etc

5. Valve stem material: stainless steel

6. Valve seat material: PTFE, EPDM, etc

7. Valve disc material: stainless steel, alloy steel, etc

8. Valve diameter: DN50-DN1000

9. Connection method: Double flange connection

10. Driving method: pneumatic actuator

Maintenance:

1. Regularly check the working status of the pneumatic actuator to ensure its normal operation.

2. Regularly clean the inside of the valve to prevent impurities from blocking.

3. Regularly replace vulnerable parts such as valve seats and discs to extend their service life.

Under normal usage conditions, a comprehensive inspection and maintenance should be conducted once a year.