Research on Corrosion Resistance: Application of Chinese Standard Flange Globe Valves in the Chemical Industry

"Research on Corrosion Resistance: Application of Chinese Standard Flange Globe Valves in the Chemical Industry"

1、 Introduction

Chinese standard flange globe valves play an important role in the chemical industry, and their corrosion resistance directly affects the stability and safety of the production process. This article aims to explore the corrosion resistance performance of Chinese standard flange globe valves and their application in the chemical industry, providing reference for engineering practice in related fields.

2、 Corrosion resistance performance of Chinese standard flange globe valves

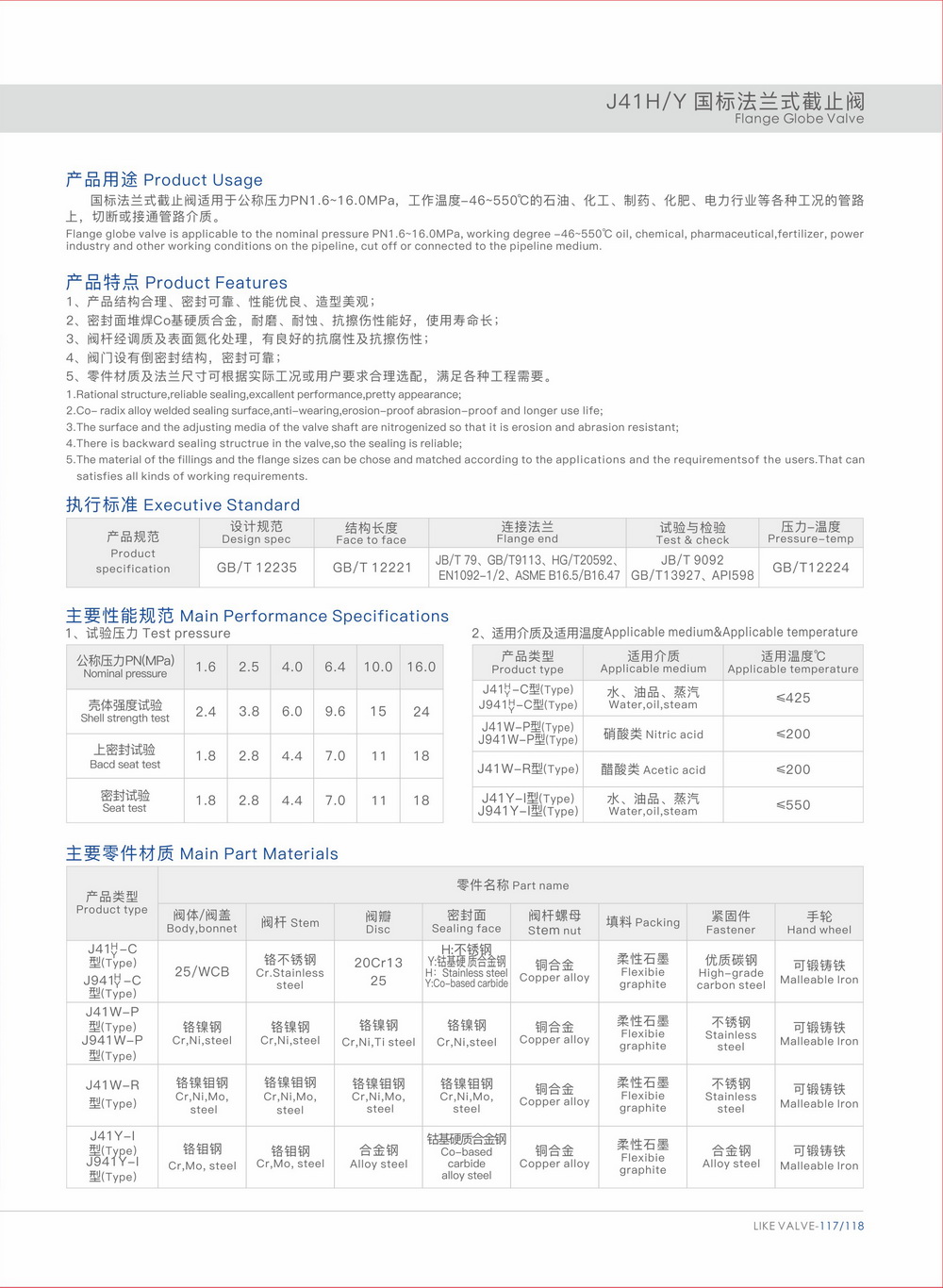

The corrosion resistance of Chinese standard flange globe valves mainly depends on their material and manufacturing process. Common corrosion-resistant materials include stainless steel, duplex steel, etc., which can maintain good stability in corrosive media such as acid and alkali. In addition, by optimizing the manufacturing process and surface treatment, the corrosion resistance of the valve can be further improved.

In the chemical industry, Chinese standard flange globe valves are widely used in pipeline systems for various corrosive media. Its stable sealing performance and long service life make it an ideal choice for handling corrosive fluids. At the same time, Chinese standard flange globe valves also have the advantages of simple structure, easy manufacturing and maintenance, which can meet the performance and safety requirements of the chemical industry for valves.

3、 Application cases of Chinese standard flange globe valves in the chemical industry

Taking the dual phase steel high-pressure flange globe valve as an example, it is widely used in the chemical industry. Dual phase steel material has good resistance to chloride ion stress corrosion and sulfide stress corrosion, as well as high mechanical strength, making it widely used in industries such as petroleum, natural gas, and chemical industry. In chemical corrosion conditions, dual phase steel high-pressure flange globe valves can reliably cut off or connect pipeline media, ensuring stable operation of the production process.

In addition, Chinese standard flange globe valves are widely used in industrial steam pipeline systems. In industrial steam pipelines in the factory area, due to the characteristics of long pipeline length, high parameters, large thermal expansion, and complex environment, higher requirements are put forward for the corrosion resistance performance of valves. The excellent performance of the Chinese standard flange globe valve makes it an ideal choice for these complex working conditions.

4、 Strategies for improving the corrosion resistance of Chinese standard flange globe valves

To improve the corrosion resistance of Chinese standard flange globe valves, the following strategies can be adopted:

Select materials with excellent corrosion resistance, such as duplex steel, stainless steel, etc., to cope with the corrosion of corrosive media on the valve.

Optimize manufacturing processes and surface treatment techniques, such as using nitriding treatment, spraying anti-corrosion coatings, etc., to improve the surface corrosion resistance of valves.

Regularly maintain and inspect valves, promptly identify and address potential corrosion issues, ensuring the normal operation of valves and extending their service life.

5、 Conclusion

The Chinese standard flange globe valve has a wide range of application prospects in the chemical industry. By selecting corrosion-resistant materials, optimizing manufacturing processes, and conducting regular maintenance and inspections, the corrosion resistance performance of valves can be further improved, ensuring their safe and stable operation in the chemical industry. In the future, with the continuous progress of materials science and manufacturing technology, the corrosion resistance performance of Chinese standard flange globe valves will be further improved, providing more reliable guarantees for the development of the chemical industry.

Please note that the content described in this article is based on existing knowledge and experience, and in practical applications, specific analysis and selection need to be carried out based on specific working conditions and valve models. Meanwhile, when selecting, installing, and maintaining valves, relevant standards and specifications should be followed to ensure safe and reliable operation.