Connection protection device for Chinese forged steel threaded/socket welded gate valves and industrial pipeline systems

Connection protection device for Chinese forged steel threaded/socket welded gate valves and industrial pipeline systems

Introduction:

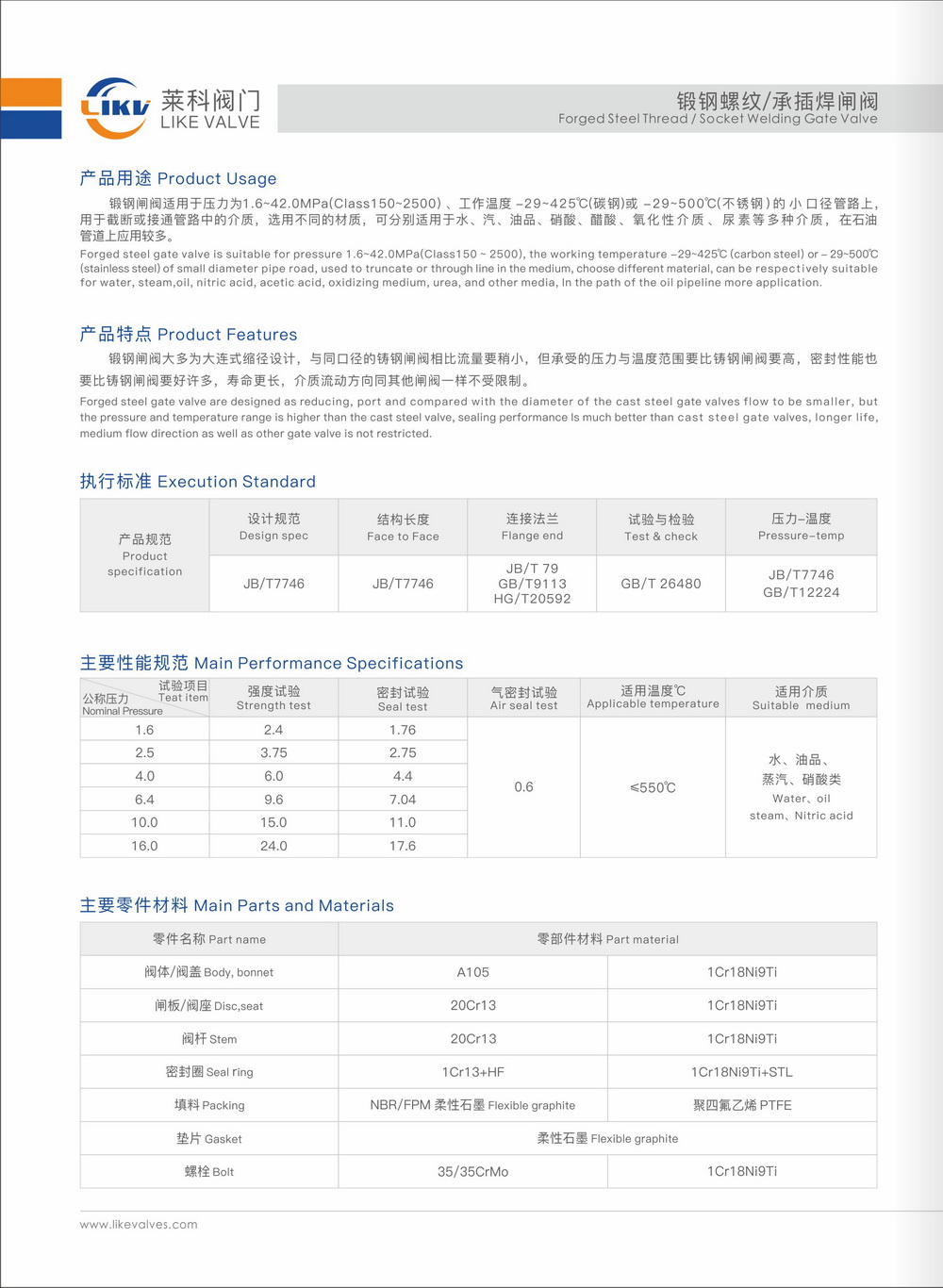

Ensuring stable fluid flow and safety control is crucial in complex industrial pipeline systems. In this process, a key component - forged steel threaded/socket welded gate valves play a crucial role. They not only provide a reliable connection method, but also ensure the sealing of the system and the flexibility of operation. This article will delve into the structural characteristics, working principles, and importance of forged steel threaded/socket welded gate valves in different industrial applications.

1、 What is a forged steel threaded/socket welded gate valve?

Forged steel threaded/socket welded gate valve is a device specifically designed to control the flow of media in industrial pipelines. It consists of two main parts: a steel valve body made through precision forging technology, and an interface connected to the pipeline through threading or socket welding. This valve design aims to provide high strength, high pressure resistance, and ensure good sealing performance.

2、 Working principle

The core of forged steel threaded/socket welded gate valves lies in their internal valve plate (or valve core). When it is necessary to close the fluid, the valve plate will move along the axis direction to completely block the flow path; When it is necessary to open the fluid, the valve plate is moved away, allowing the medium to flow smoothly. The design of threaded/socket welding allows the valve to be firmly connected to the pipeline, preventing leakage and withstanding high working pressure.

3、 Features and advantages

1. High reliability: The precision forged steel valve body has excellent strength and pressure resistance, suitable for high demand working environments.

2. Tight connection: The threaded or socket welding method provides excellent sealing performance, effectively preventing leakage.

3. Easy to install and maintain: The standard connection method simplifies the installation process and also facilitates future maintenance and replacement.

4. Multi scenario applicability: Whether it is threaded connection or socket welding connection, it can adapt to different industrial application requirements.

5. Strong durability: The forged steel material and high standard production process ensure the long-term stability and durability of the valve.

4、 Application field

Due to its excellent connection performance and sealing effect, forged steel threaded/socket welded gate valves are widely used in many important industries such as petroleum, chemical, natural gas, power, and others. This type of valve is particularly favored in situations where long-term reliable operation is required and high safety performance is required.

Conclusion:

As an important component of industrial pipeline systems, forged steel threaded/socket welded gate valves play an important role in ensuring the safety and reliability of industrial fluid control due to their excellent durability, strong load-bearing capacity, and simple installation method. With the continuous progress of materials science and manufacturing technology, future forged steel threaded/socket welded gate valves will become more precise and intelligent, further meeting the needs of industrial development and protecting our production and living environment.