Pneumatic flange gate valve: a key component of industrial pipeline control

Pneumatic flange gate valve: a key component of industrial pipeline control

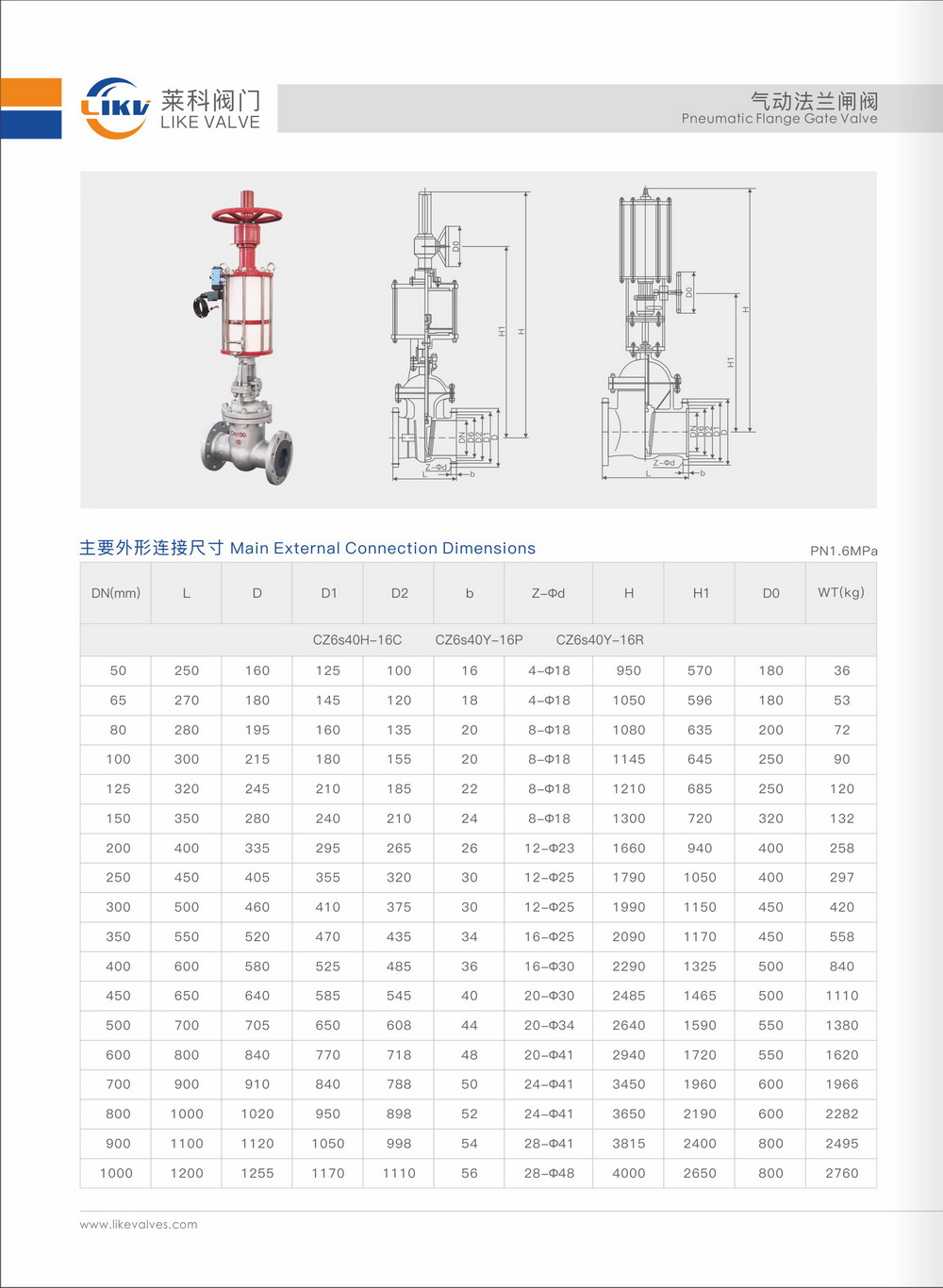

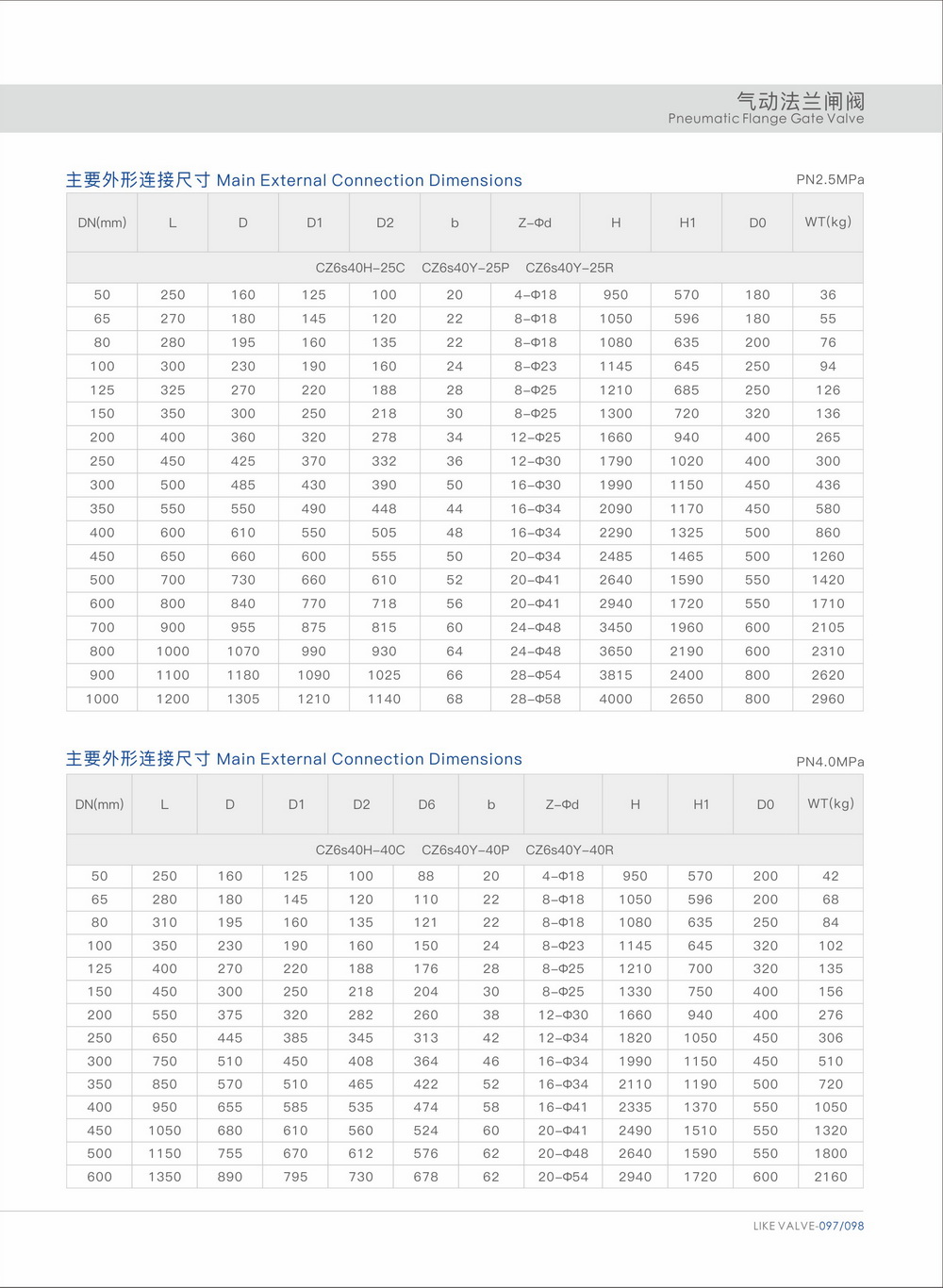

In modern industrial process control systems, pneumatic flange gate valves play a crucial role. This type of valve utilizes aerodynamic force as the driving force to open or close the valve by controlling the pressure and flow direction of air, thereby achieving precise control of fluid flow. This article will introduce the working principle, characteristics, and application scenarios of pneumatic flange gate valves, helping readers better understand their importance and function.

What is a pneumatic flange gate valve?

Pneumatic flange gate valve is a device used to open or close the flow of medium in pipelines, which combines the characteristics of pneumatic actuators and flange connections. The pneumatic actuator is responsible for responding to control signals and pushing the valve stem to perform switch actions; And flange connection refers to the connection method between valves and pipelines, which is fastened with bolts for easy installation and maintenance.

operational principle

When the control signal is delivered, the piston inside the pneumatic actuator is subjected to the action of compressed air, generating linear motion. This movement is transmitted to the gate through the valve stem, causing the gate to rise or fall, thereby completing the opening or closing action. In most cases, pneumatic actuators include springs or other forms of reset mechanisms to ensure that the valve can be quickly closed in the event of a loss of air supply, providing safety assurance.

Features and advantages

1. Remote control capability: Due to the reliance on compressed air for operation, pneumatic flange gate valves can easily achieve remote control, suitable for industrial environments that require centralized control.

2. Quick response: Pneumatic actuators have a fast response speed and can complete opening and closing actions in a short period of time, especially suitable for situations where fluid needs to be quickly cut off.

3. High safety: In the event of a gas source interruption, most pneumatic flange gate valves are designed with an automatic closing function, which can prevent accidents in emergency situations.

4. Simple maintenance: Due to the simple structure of pneumatic actuators, there is relatively little maintenance and upkeep work, and they are not easily affected by the environment.

5. Cost effectiveness: Compared to other types of driving methods (such as electric), pneumatic systems typically have lower installation and maintenance costs.

application area

Pneumatic flange gate valves are widely used in various fields such as petroleum, chemical, metallurgy, and power, especially suitable for situations with high requirements for control accuracy, response speed, and safety. For example, they are often used as globe valves, regulating valves, or throttling valves, playing a critical role in pipeline systems transporting liquids, gases, or powdered materials.

epilogue

In summary, pneumatic flange gate valves are an indispensable component of industrial process control. Their design is simple and efficient, and they can work reliably under various extreme conditions. Understanding its working principle and application can help make wiser decisions when designing and operating industrial pipeline systems. With the continuous development of automation and intelligent technology, the application of pneumatic flange gate valves will also become more widespread, and their role in industrial safety and efficiency improvement will become increasingly significant.