Application of PQ side mounted two way sealed eccentric hemisphere valve

It is suitable for sewage treatment, pulp, alumina, urban heating, petrochemical, gas, slurry, coal ash, etc.

Product features

1. Large circulation area and small flow resistance. This is because after opening, the valve core is located in the ball chamber, and the fluid is straight through.

2. Small operating torque, turn 90 degrees to open and close, easy to operate.

3. Tight seal; double eccentric metal hard seal. The structure does not affect the opening and closing, which is the most significant feature of hemisphere valve.

4. Long service life, wear-resistant sealing pair, with compensation, valve seat can be adjusted or replaced.

Executive standard for PQ side mounted bidirectional eccentric hemisphere valve

| Design criteria | Structural length | Flange standard | Test and inspection |

| GB/T 12237-2007 | GB/T 12221-2005 | GB-T9113-2000、EN1092 | GB/T13927-2008、API598 |

Main technical parameters

| Nominal pressure PN(MPa) | 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 |

| Maximum working pressure at normal temperature(MPa) | 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 |

| Shell strength test pressure(MPa) | 0.9 | 1.5 | 2.4 | 3.8 | 6.0 | 9.6 |

| Airtight test pressure(MPa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| High pressure seal test pressure(MPa) | 0.66 | 1.1 | 1.8 | 2.75 | 4.4 | 7.1 |

| Leakage rate | < 0.1*DNmm³/S (in accordance with API 598) | |||||

| Applicable temperature (℃) | Soft seal:-40℃~+200℃ | |||||

| Applicable medium | Natural gas, steam, oil products, acids, alkalis, pulverized coal, coal ash, waste residue and mud Including granular, fiber and other media | |||||

| Transmission form | Worm gear drive, electric drive, pneumatic drive, hydraulic drive | |||||

PQ Materials of main parts of side mounted two way eccentric hemisphere valve

| Valve body and pressure plate | WCB | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti | ZG15Cr1Mo1V |

| sphere | WCB+Cr | 1Cr18Ni9Ti Special surface treatment | 0Cr18Ni12Mo2Ti Special surface treatment | 25Cr2Mo1V Special surface treatment |

| Stem | 20Cr13 | 1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti | 25Cr12Mo1V |

| valve seat | Q235A+PTFEButt welding | 1Cr18Ni9Ti/PTFE | 0Cr18Ni12Mo2Ti/PTFE | 25Cr12Mo1/PTFE |

| filler | Flexible graphite | Flexible graphite | Flexible graphite | Flexible graphite |

| Bolt | 35 | 0Cr18Ni9 | 0Cr18Ni9 | 15Cr1Mo1V |

| Nut | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 20CrMo |

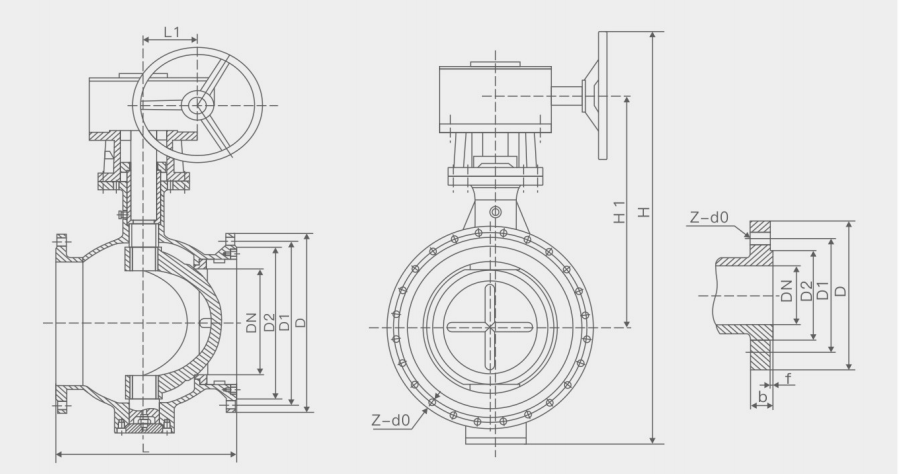

PQ Drawing of side mounted two way seal eccentric hemisphere valve

PQ Main connecting dimensions of PN1.0MPa side mounted two way seal eccentric hemisphere valve

| DN | L | D | D1 | D2 | Z-d0 | f | b | H |

| 40 | 165 | 150 | 110 | 84 | 4-18 | 2 | 18 | 210 |

| 50 | 178 | 165 | 125 | 99 | 4-18 | 2 | 20 | 230 |

| 65 | 190 | 185 | 145 | 118 | 4-18 | 2 | 20 | 245 |

| 80 | 203 | 200 | 160 | 132 | 8-18 | 2 | 20 | 265 |

| 100 | 229 | 220 | 180 | 156 | 8-18 | 2 | 22 | 310 |

| 125 | 254 | 250 | 210 | 184 | 8-18 | 2 | 22 | 350 |

| 150 | 267 | 285 | 240 | 211 | 8-22 | 2 | 24 | 395 |

| 200 | 292 | 340 | 295 | 266 | 8-22 | 2 | 24 | 435 |

| 250 | 330 | 395 | 350 | 319 | 12-22 | 2 | 26 | 480 |

| 300 | 356 | 445 | 400 | 370 | 12-22 | 2 | 26 | 550 |

| 350 | 381 | 505 | 460 | 429 | 16-22 | 2 | 26 | 620 |

| 400 | 430 | 565 | 515 | 480 | 16-26 | 2 | 26 | 670 |

| 450 | 502 | 615 | 565 | 530 | 20-26 | 2 | 28 | 700 |

| 500 | 550 | 670 | 620 | 582 | 20-26 | 2 | 28 | 760 |

| 600 | 660 | 780 | 725 | 682 | 20-30 | 2 | 34 | 850 |

| 700 | 770 | 895 | 840 | 794 | 24-30 | 5 | 34 | 920 |

| 800 | 880 | 1015 | 950 | 901 | 24-33 | 5 | 36 | 1100 |

| 900 | 1000 | 1115 | 1050 | 1001 | 28-33 | 5 | 38 | 1300 |

| 1000 | 1100 | 1230 | 1160 | 1112 | 28-36 | 5 | 38 | 1600 |

| 1200 | 1200 | 1455 | 1380 | 1328 | 32-39 | 5 | 44 | 1950 |