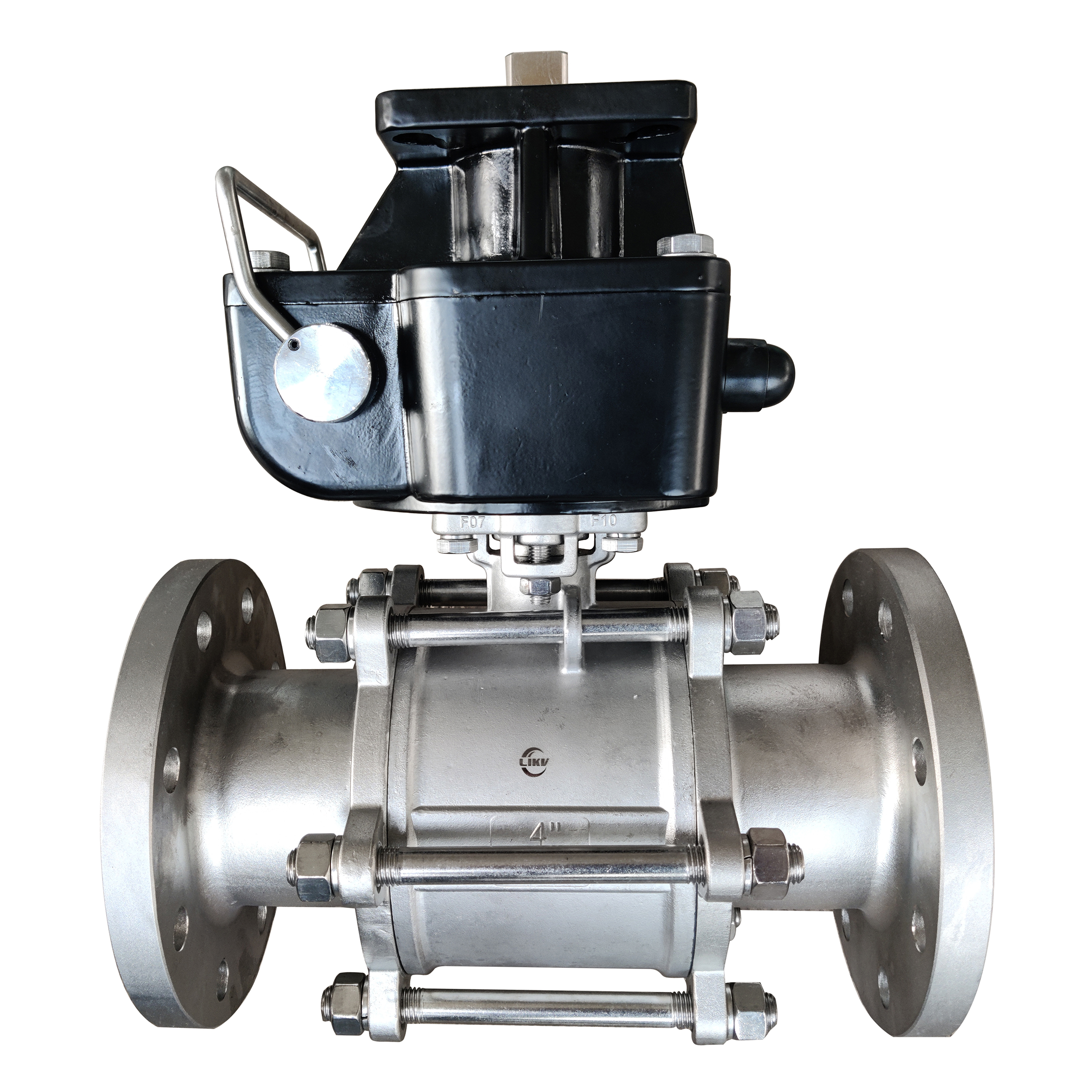

The three piece handwheel head high-pressure forged steel flange ball valve is a high-performance valve mainly used for cutting off and controlling fluid media such as liquids and gases. It has the characteristics of high pressure resistance, corrosion resistance, and reliable sealing, and is suitable for harsh working conditions.

1、 Product features:

1. High pressure resistance: Made of high-strength forged steel material, capable of withstanding pressures up to 3000PSI.

2. Corrosion resistance: The surface has undergone special treatment and has good corrosion resistance, suitable for various corrosive media.

3. Reliable sealing: Advanced sealing structure design is adopted to ensure the sealing performance of the valve under high-pressure working conditions.

4. Easy to operate: The handwheel head design is convenient for manual operation, making it convenient and fast.

5. Widely used: Suitable for pipeline systems in industries such as petroleum, chemical, metallurgy, and power.

2、 Model size comparison table:

The following is a comparison table of some models and sizes of the three piece handwheel head high-pressure forged steel flange ball valve. Please choose the specific models and sizes according to actual needs.

Model DN (mm) PN (MPa) A (mm) L (mm)

XQ341H-16C DN50 PN16 133 165

XQ341H-25C DN80 PN25 165 195

XQ341H-40C DN100 PN40 203 232

XQ341H-50C DN125 PN50 238 265

XQ341H-63C DN150 PN63 273 295

XQ341H-80C DN200 PN80 325 345

XQ341H-100C DN250 PN100 381 395

XQ341H-125C DN300 PN125 442 455

XQ341H-150C DN350 PN150 482 495

XQ341H-200C DN400 PN200 577 605

XQ341H-250C DN500 PN250 678 715

XQ341H-300C DN600 PN300 762 775

XQ341H-350C DN700 PN350 898 895

XQ341H-400C DN800 PN400 985 995

XQ341H-450C DN900 PN450 1146 1195

XQ341H-500C DN1000 PN500 1276 1295

3、 Installation and maintenance:

Before installation, please ensure that the valve meets the design requirements and the pipeline is clean and free of impurities.

2. During installation, pay attention to the direction of the valve and do not install it upside down.

3. Regularly check the sealing performance of the valve, and if there is any leakage, please replace the sealing components in a timely manner.

4. During use, avoid severe impact on the valve to prevent damage to the valve structure.

5. When not in use for a long time, the valve should be closed and protected with rust proof oil.