Optimization practice of electric flange globe valves in remote operation

"Optimization practice of electric flange globe valves in remote operation"

Abstract: With the continuous improvement of industrial automation level, the application of electric flange globe valves in industrial production is becoming increasingly widespread. However, in the actual remote operation process, electric flange globe valves have certain limitations. This article addresses these issues and proposes a series of optimization measures based on practical engineering cases, which have been verified in practice, providing new ideas for the application of electric flange globe valves in remote operation.

1、 Introduction

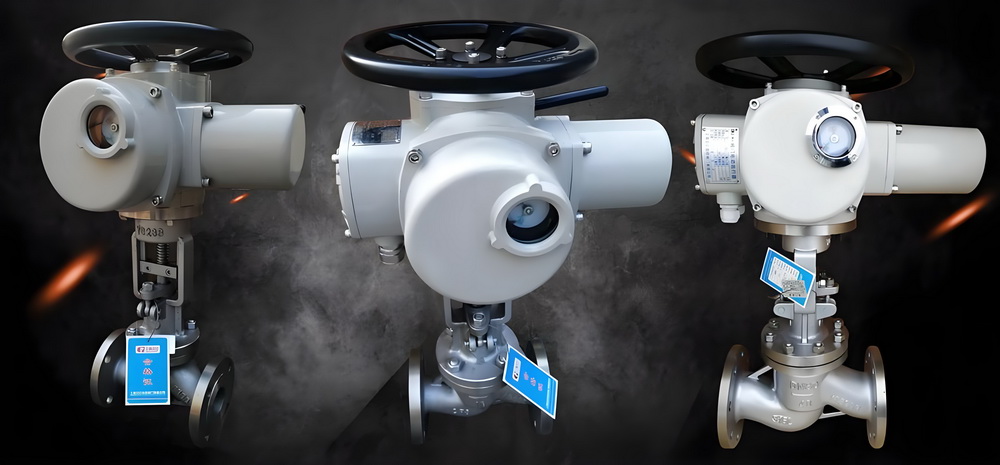

Electric flange globe valves, as an important fluid control equipment, are widely used in industries such as petroleum, chemical, power, and light industry. Compared with traditional manual valves, electric flange globe valves have advantages such as easy operation, precise control, and remote operation. However, in practical applications, there are certain problems with remote operation of electric flange globe valves due to limitations in equipment performance, environmental factors, and operator quality. This article aims to propose practical and feasible optimization measures to address these issues, in order to improve the stability and reliability of remote operation of electric flange globe valves.

2、 Problems with remote operation of electric flange globe valves

1. Unstable device performance

During remote operation, electric flange globe valves are limited by the performance of the equipment and are prone to leakage, jamming, and other phenomena, resulting in the inability of the valve to open and close normally.

2. Impact of environmental factors

The industrial site environment is complex, and electric flange globe valves are easily affected by environmental factors such as temperature, humidity, and corrosion during remote operation, leading to a decline in equipment performance.

3. Uneven quality of operators

In the actual operation process, the level of understanding and operating skills of operators for electric flange globe valves varies, which can easily lead to equipment damage due to improper operation.

4. Incomplete remote control system

The remote control system of electric flange globe valves has certain limitations, such as low control accuracy and slow response speed, which affect the remote operation effect of the valves.

3、 Optimization measures for remote operation of electric flange globe valves

In response to the above issues, this article proposes optimization measures from the following aspects:

1. Equipment selection optimization

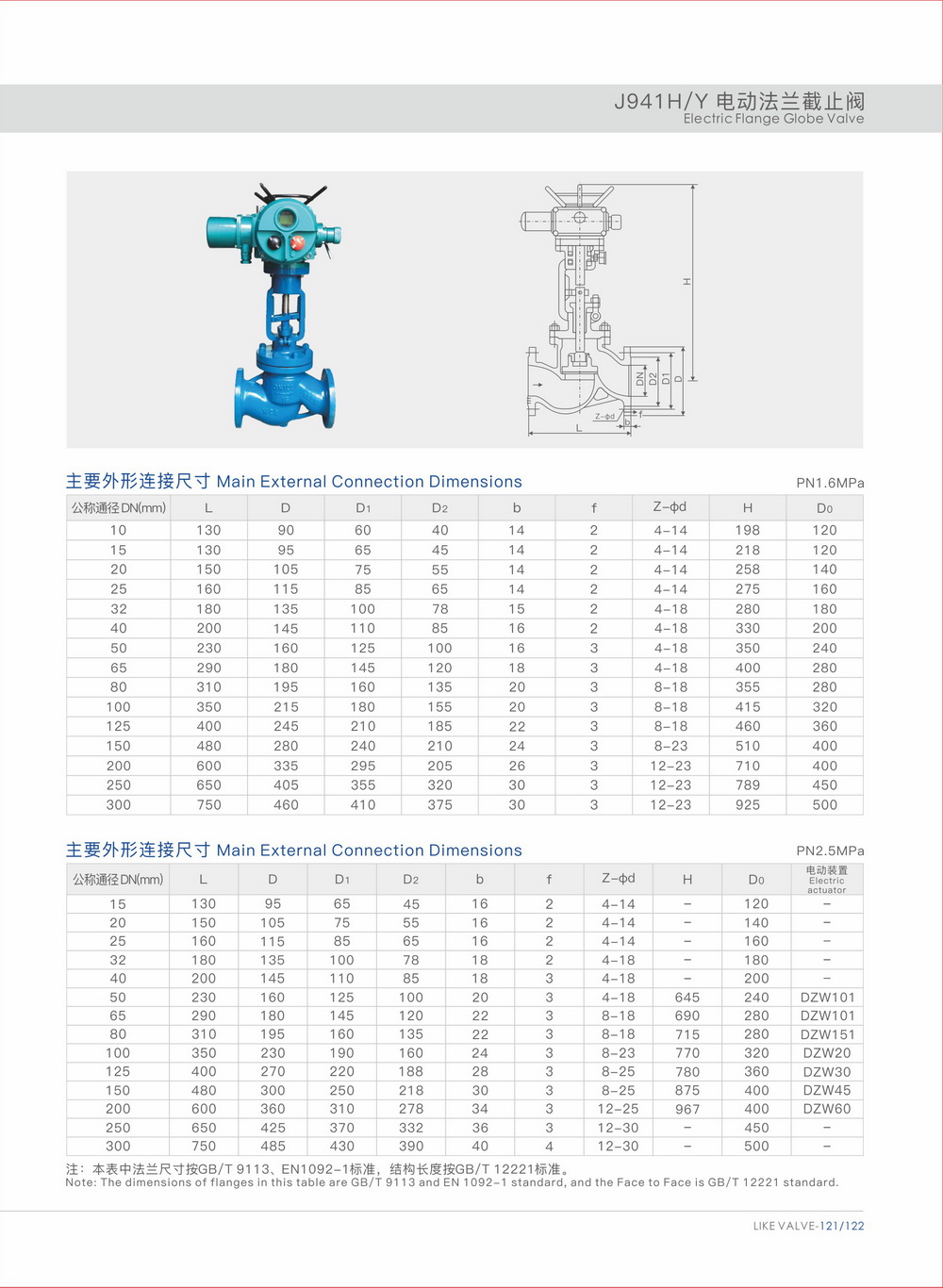

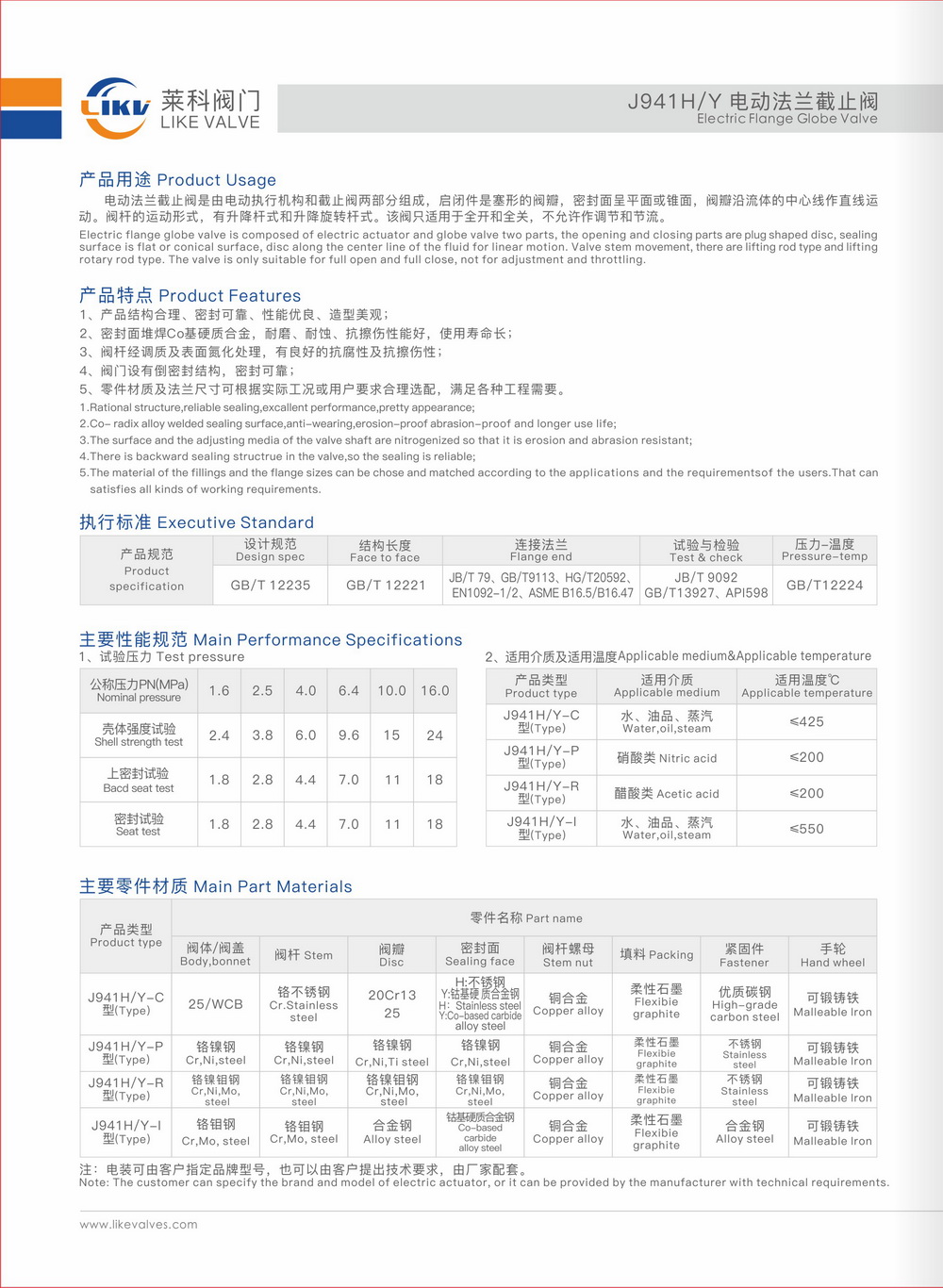

(1) Select high-performance electric actuators to improve the speed and accuracy of valve opening and closing.

(2) Select appropriate sealing materials to improve the sealing performance of the valve.

(3) Select valve materials that are corrosion-resistant and wear-resistant according to actual working conditions.

2. Environmental adaptability optimization

(1) Apply anti-corrosion treatment to electric flange globe valves to improve their service life in harsh environments.

(2) Using electric actuators with high protection levels to reduce the impact of environmental factors on equipment performance.

3. Operator training

Strengthen the skill training of operators to improve their understanding and operational skills of electric flange globe valves.

4. Improvement of remote control system

(1) Adopting advanced control algorithms to improve the response speed and accuracy of the control system.

(2) Introducing fault diagnosis function, real-time monitoring of equipment operation status, timely detection and handling of problems.

4、 Practical verification

In the actual engineering of a chemical plant, we have taken the above optimization measures to address the problems of remote operation of electric flange globe valves. After a period of operation, the performance of the equipment has been significantly improved, and the stability of remote operation has been greatly improved, specifically manifested in:

1. The phenomenon of valve leakage has been effectively controlled, reducing safety hazards in the production process.

2. The speed and accuracy of valve opening and closing have been improved, meeting the production process requirements.

3. The operator's operational skills for electric flange globe valves have been improved, reducing the equipment failure rate.

4. The remote control system operates stably, and the fault diagnosis function promptly detects and handles equipment hazards.

5、 Conclusion

This article proposes a series of optimization measures for the problems existing in remote operation of electric flange globe valves, and has been verified in practical engineering. The results indicate that these optimization measures can effectively improve the stability and reliability of remote operation of electric flange globe valves, providing strong support for industrial production. In the future, with the continuous development of automation technology, the application of electric flange globe valves in remote operation will be more widespread, bringing higher benefits to industrial production.