Improving system response speed: Real time control characteristic analysis of electric flange globe valves

Improving system response speed: Real time control characteristic analysis of electric flange globe valves

In industrial pipeline systems, electric flange globe valves are widely used in various industrial fields due to their efficient operating performance and reliable sealing effect. Among them, the real-time control characteristics of valves are one of their important performance indicators, which is of great significance for improving the response speed of the system and ensuring the smooth progress of production.

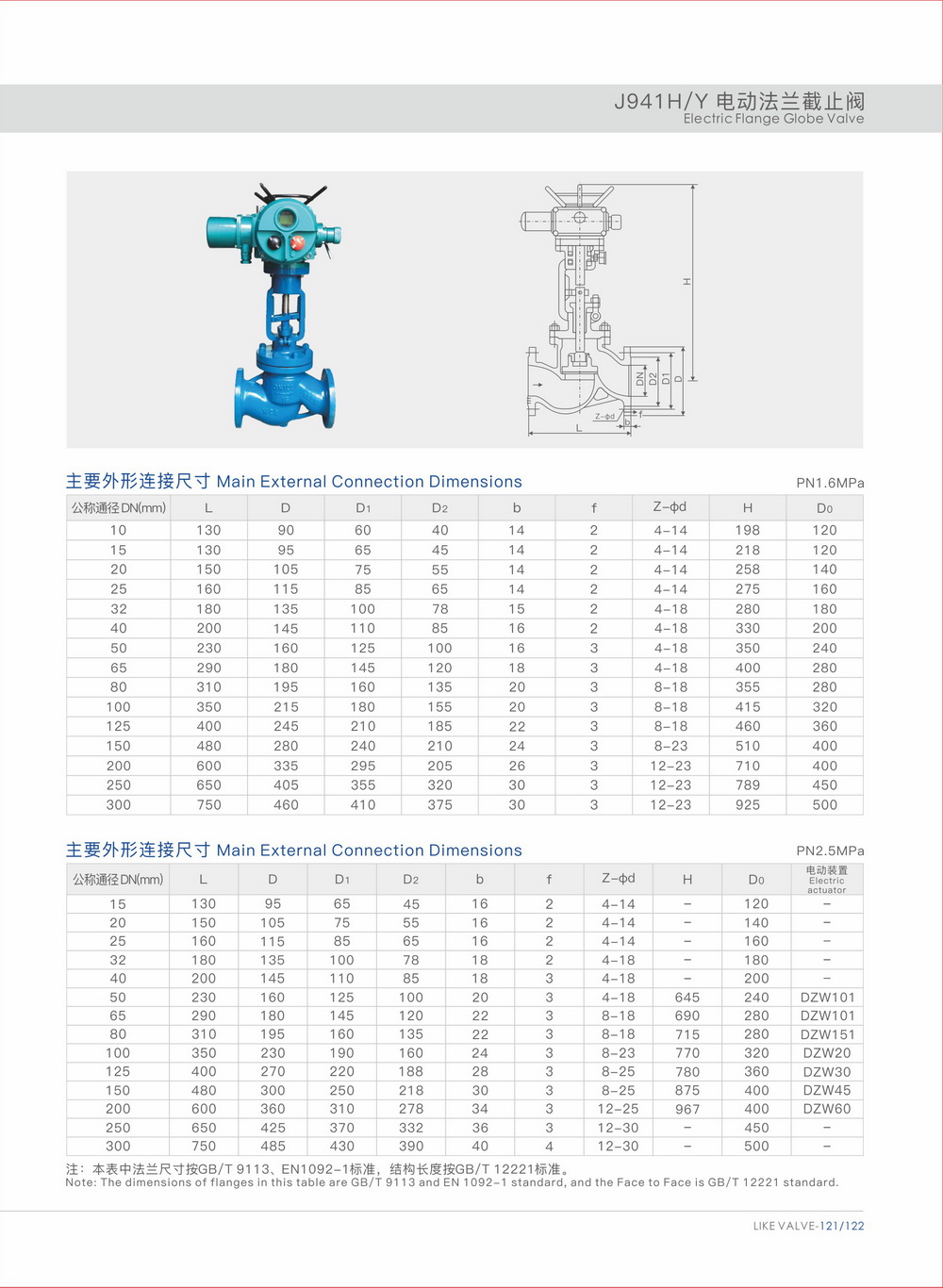

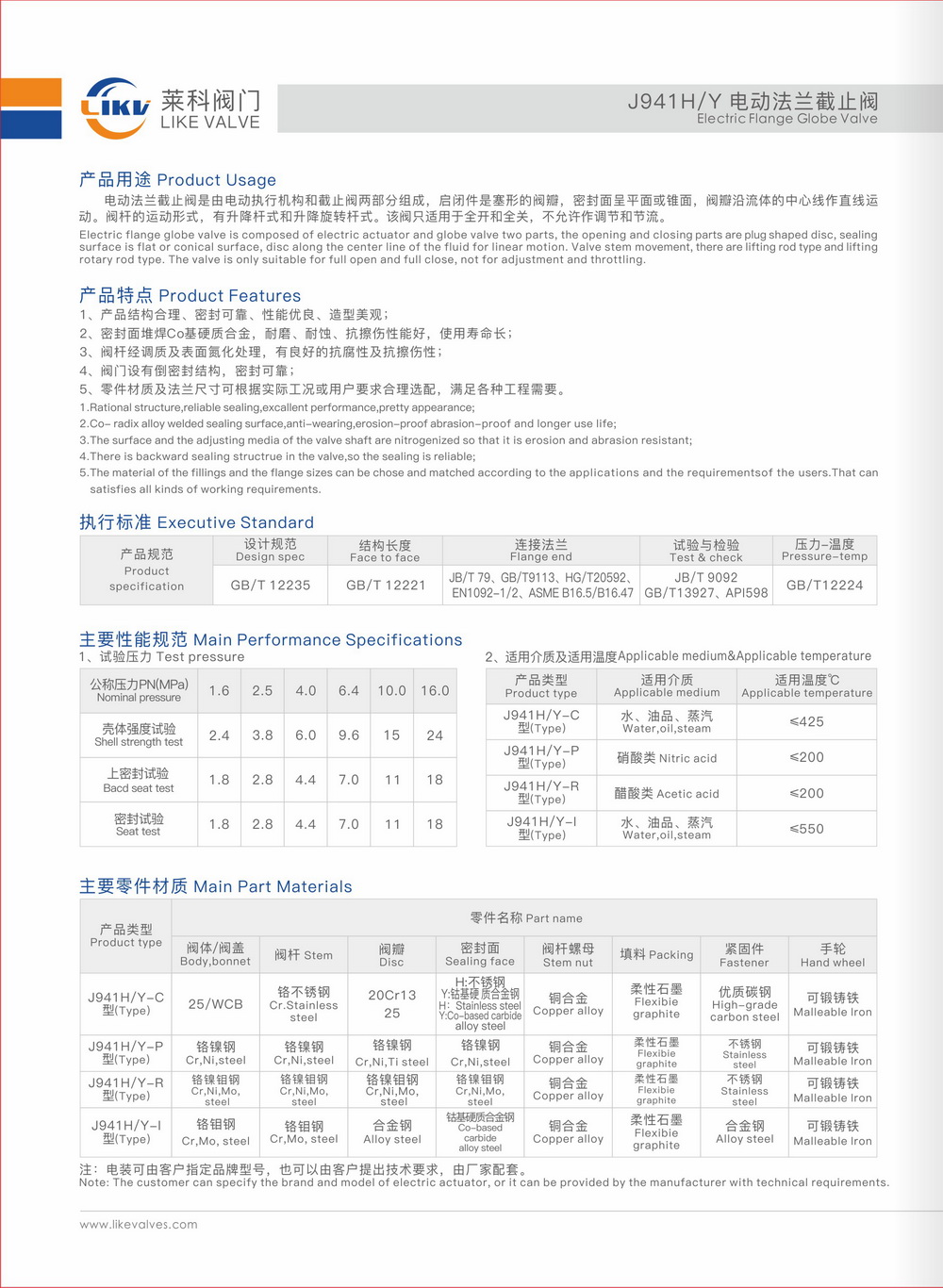

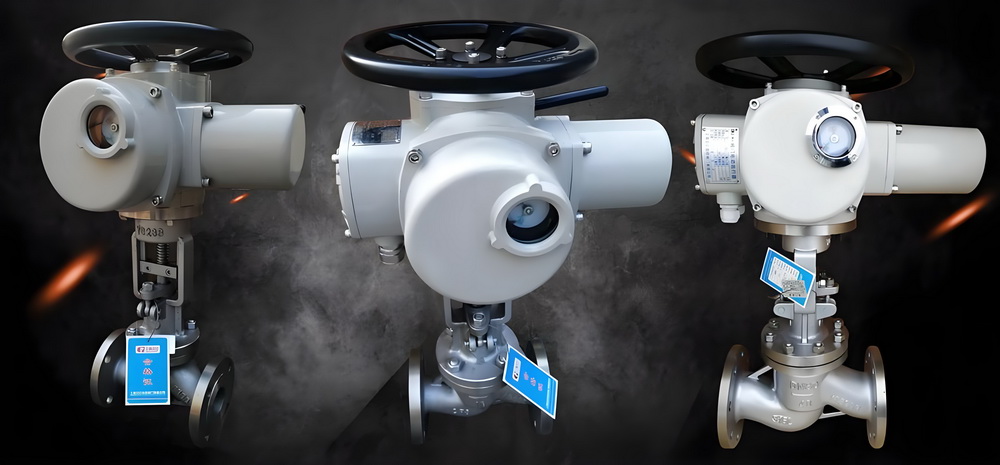

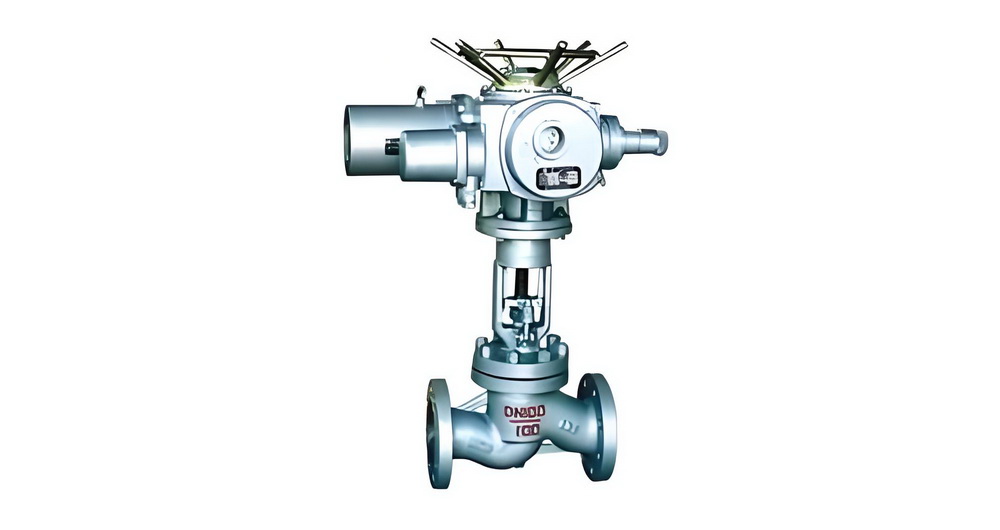

Firstly, let's explore the basic structure of electric flange globe valves. This type of valve mainly consists of components such as valve body, valve cover, valve disc, valve stem, sealing ring, and electric actuator. Among them, the valve body is the main part of the valve, usually connected to the pipeline system through flange connection. The valve cover covers above the valve body, providing protection for the valve stem. The valve disc is a key component for achieving sealing, which is located in the inner cavity of the valve body and achieves sealing through close contact with the valve seat. The valve stem is an important component that connects the electric actuator and the valve disc. It transmits the power of the actuator to the valve disc, achieving the opening and closing of the valve. The sealing ring is used to improve the sealing performance of the valve and prevent medium leakage. Finally, electric actuators are the power source for driving valve operation, which can be electric motors, pneumatic or hydraulic actuators, etc.

Next, we will analyze the working principle of the electric flange globe valve. When the electric actuator receives a control signal, it will drive the valve stem to move up and down. As the valve stem moves, the valve disc will also rise or fall accordingly. When the valve disc rises and leaves the valve seat, the valve opens and the medium can pass through; When the valve disc descends and comes into close contact with the valve seat, the valve closes and the flow of the medium is cut off. In this process, the sealing ring plays an important role in ensuring that the valve does not leak when closed. In addition, precise control of flow can be achieved by adjusting the stroke length of the actuator.

The structural characteristics of electric flange globe valves are mainly reflected in the following aspects:

1. Highly integrated: The main components of the valve are integrated into the valve body, which makes the valve structure compact and occupies a small area.

2. Easy to operate: Driven by an electric actuator, it is easy to operate and has a fast response speed. Users only need to send instructions through the control system to achieve remote control.

3. Good sealing performance: High quality sealing materials and carefully designed sealing structures are used to ensure that the valve can maintain good sealing effects under various working conditions.

4. Safety and reliability: The electric flange globe valve has multiple protective measures, such as overload protection, leakage protection, etc., to ensure the safe and reliable operation of the equipment.

5. Wide applicability: Due to the use of flange connection, the valve can easily connect with other flange connected pipeline components, making it suitable for various industrial fields.

The real-time control characteristics of electric flange globe valves are mainly reflected in their fast response and precise control. Due to the use of electric actuators as power sources, valves can achieve millisecond level rapid response, which is particularly important for situations that require quick shut-off or flow regulation. Meanwhile, by combining with modern control systems, precise control of valve opening can be achieved, thereby meeting the precise requirements for flow control in the production process.

In summary, electric flange globe valves play a crucial role in industrial pipeline systems due to their efficient working principle and unique structural characteristics. Understanding its working principle and structural characteristics helps us to better choose and use this valve, thereby ensuring the safety, efficiency, and reliability of industrial production.