Case study: Successful application of electric flange globe valves in large-scale industrial projects

Case study: Successful application of electric flange globe valves in large-scale industrial projects

1、 Preface

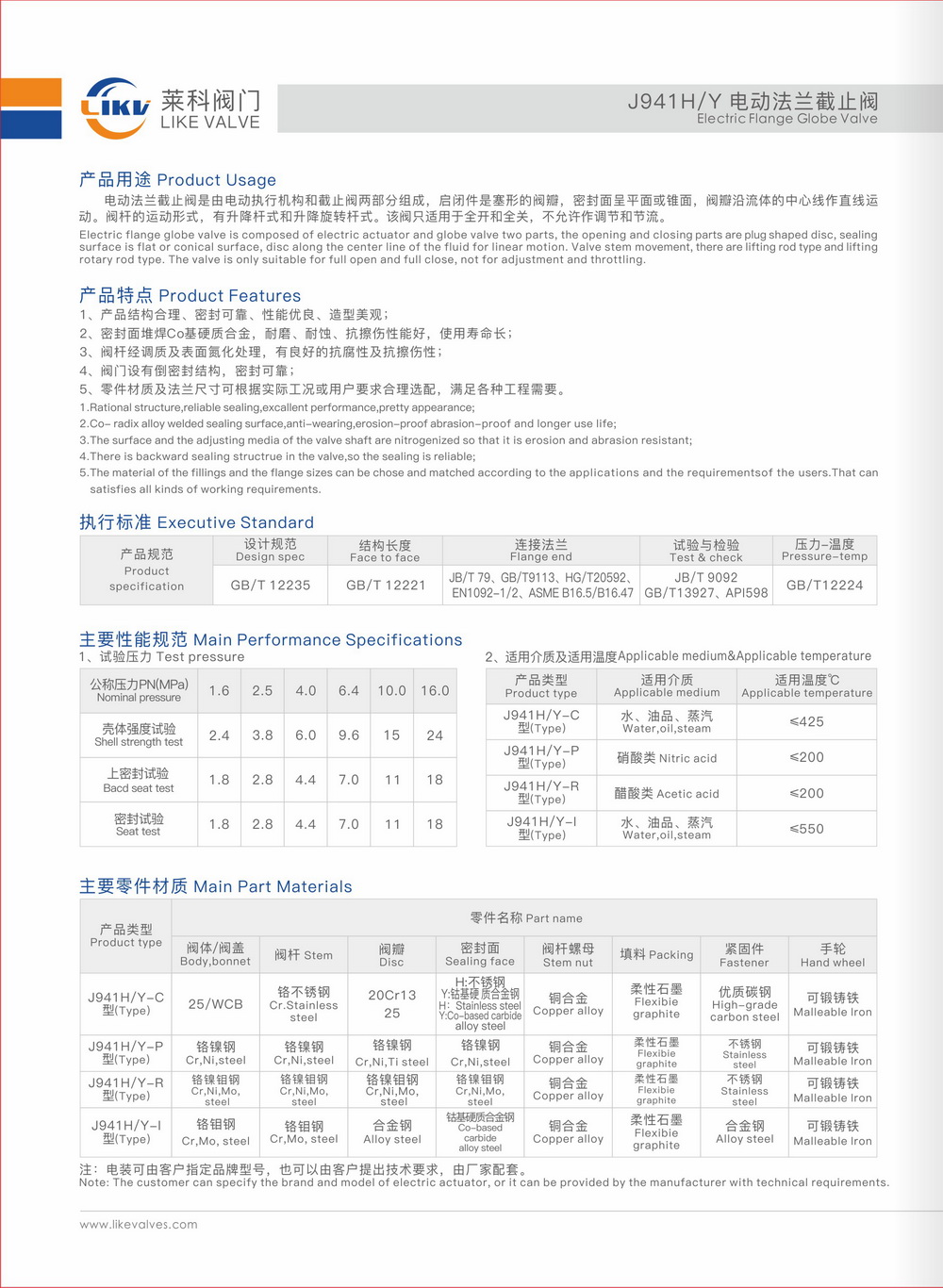

Electric flange globe valves play a crucial role in large-scale industrial projects. They play a crucial role in fluid control and process automation. This article will explore in depth the application of electric flange globe valves in large-scale industrial projects through a specific case study, as well as how to ensure their successful operation and long-term reliability.

2、 Project background

In a large-scale petrochemical project, a complex fluid transportation and control system needs to be constructed to ensure the smooth progress of the production process. In this project, the electric flange globe valve was selected as the main fluid control equipment, responsible for accurately controlling the flow rate and pressure of the medium in different production stages.

3、 The selection process of electric flange globe valves

1. Analysis of working medium

The project team first conducted a detailed analysis of the working medium, including its chemical composition, temperature, pressure and other parameters. These pieces of information are crucial for selecting the appropriate valve body materials, seals, and driving methods.

2. Environmental condition assessment

Considering the environmental conditions of the project location, such as temperature fluctuations, humidity, corrosiveness, etc., the project team has specially designed the material and structure of the electric flange globe valve to ensure its normal operation in harsh environments.

3. Technical specifications and performance requirements

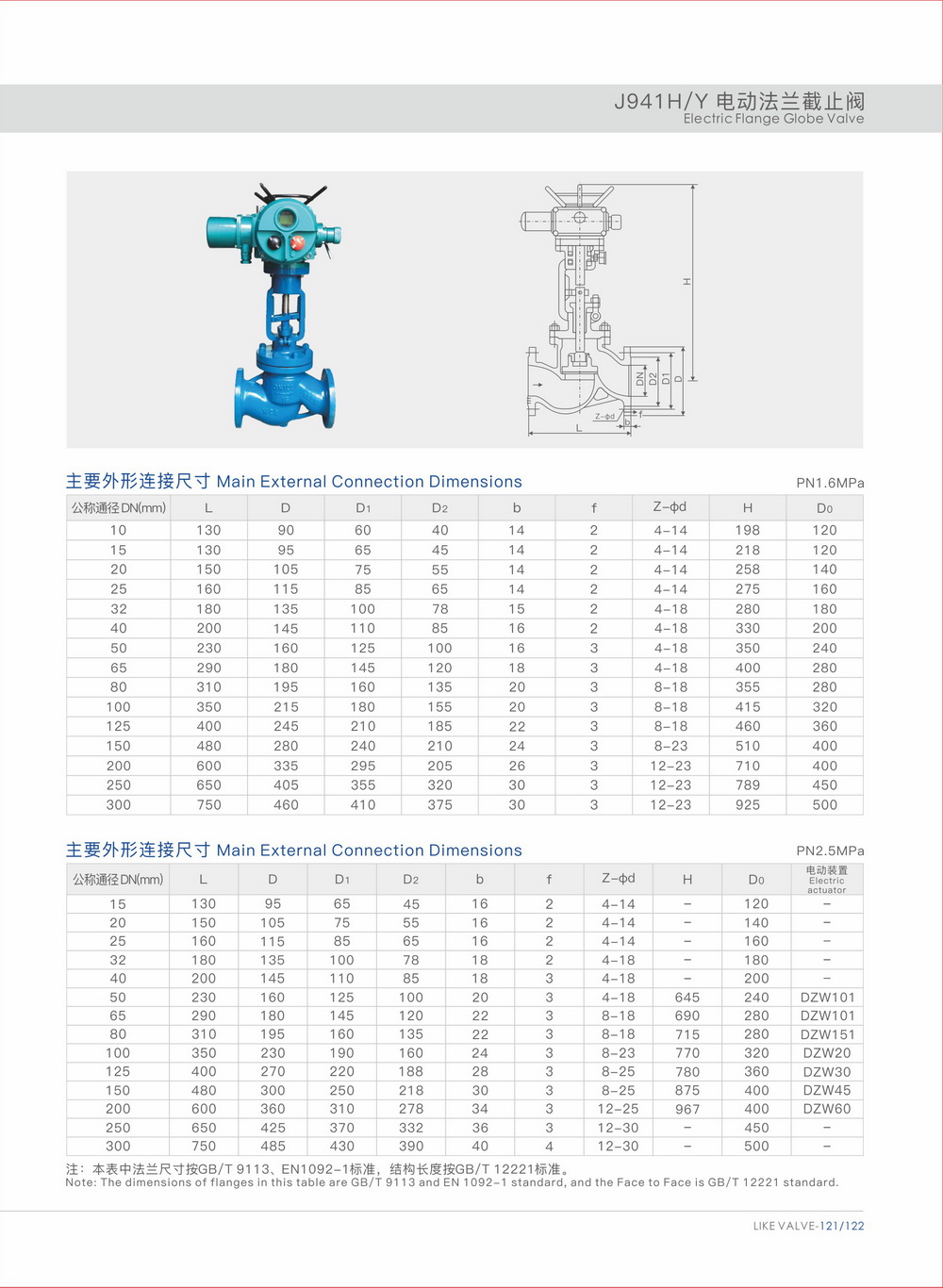

According to the engineering design requirements, the project team has listed the technical specifications and performance requirements of the electric flange globe valve, including nominal diameter, nominal pressure, sealing performance, service life, etc. These parameters have become the main basis for selection.

4. Supplier evaluation

When selecting suppliers, the project team comprehensively considers factors such as the supplier's brand reputation, technical strength, product quality, and after-sales service. In the end, we chose a supplier with a good reputation in the industry.

4、 The successful application of electric flange globe valves

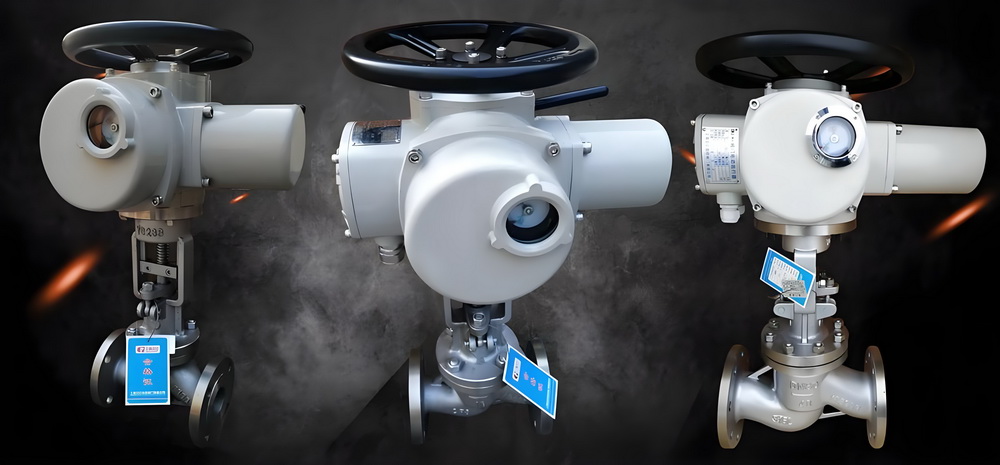

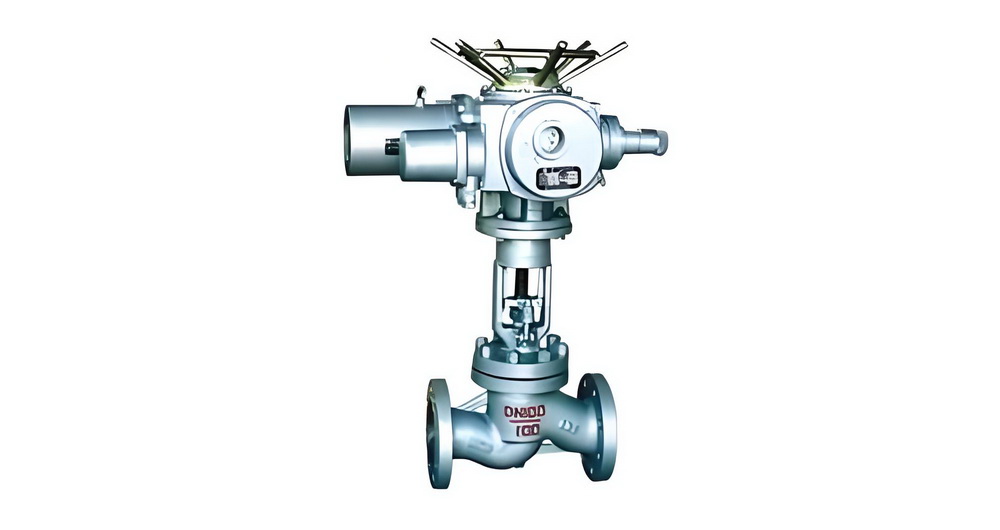

During the project implementation process, the electric flange globe valve is installed at key control nodes, responsible for accurately controlling the flow and pressure of the medium. Through strict testing and debugging, the performance of the valve has been ensured to meet the design requirements.

5、 Project Results and Summary

After a period of operation, the electric flange globe valve performed well in this project, effectively ensuring the smooth progress of the production process. Their efficient performance and long-term reliability have been recognized by the project team.

Through this case, we can see that in large-scale industrial projects, the correct selection and application of electric flange globe valves is the key to ensuring the normal operation of fluid control systems. The project team needs to conduct scientific selection and strict construction management based on a thorough understanding of the working medium, environmental conditions, and technical requirements. Only in this way can we ensure the success of electric flange globe valves in practical applications.