Accurate selection: How to choose a suitable electric flange globe valve based on the usage environment

Accurate selection: How to choose a suitable electric flange globe valve based on the usage environment

1、 Preface

In modern industrial production, electric flange globe valves are widely used in various fluid control systems due to their precise control, easy operation, safety and reliability. However, how to choose a suitable electric flange globe valve based on the specific usage environment is an important issue that engineers face when designing and implementing projects. This article will provide a detailed introduction to how to scientifically select electric flange globe valves to ensure their optimal performance under various working conditions.

2、 Using environmental analysis

1. Working medium

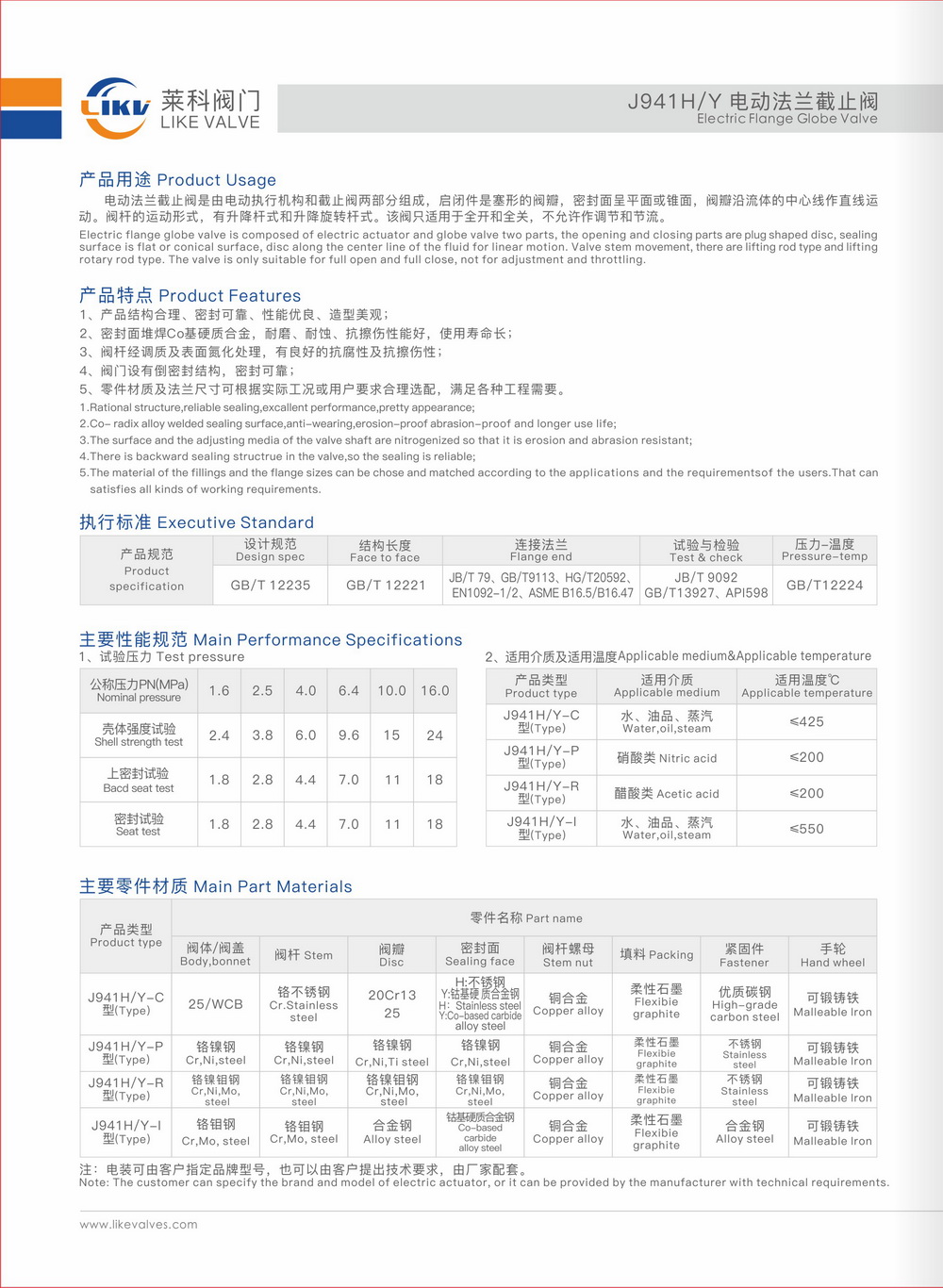

Firstly, it is necessary to clarify the working medium that the electric flange globe valve needs to control, such as its properties (such as water, oil, gas, etc.), temperature, pressure, etc. Different media may require different materials of valve bodies and sealing materials, as well as corresponding valve designs.

2. Installation position

The installation position will affect the size and structural design of the valve. For example, pipeline systems with limited space may require miniaturized valves, while remote operation may require extended handles or the use of electric or pneumatic drives.

3. Operation frequency

Determine the type and driving method of the valve based on its switching frequency. High frequency operation may require the selection of electric valves with fast response characteristics, while low frequency operation may require the selection of more economical pneumatic or manual valves.

4. Environmental conditions

Including temperature, humidity, corrosiveness, explosion hazard, etc. Extreme temperatures may require special materials and insulation measures, while corrosive environments require corrosion-resistant materials and seals.

3、 Key points for selecting electric flange globe valves

1. Material selection

Select suitable valve bodies and sealing materials based on the properties of the working medium and environmental conditions. For example, for corrosive media, corrosion-resistant materials such as stainless steel, alloys, etc. should be selected.

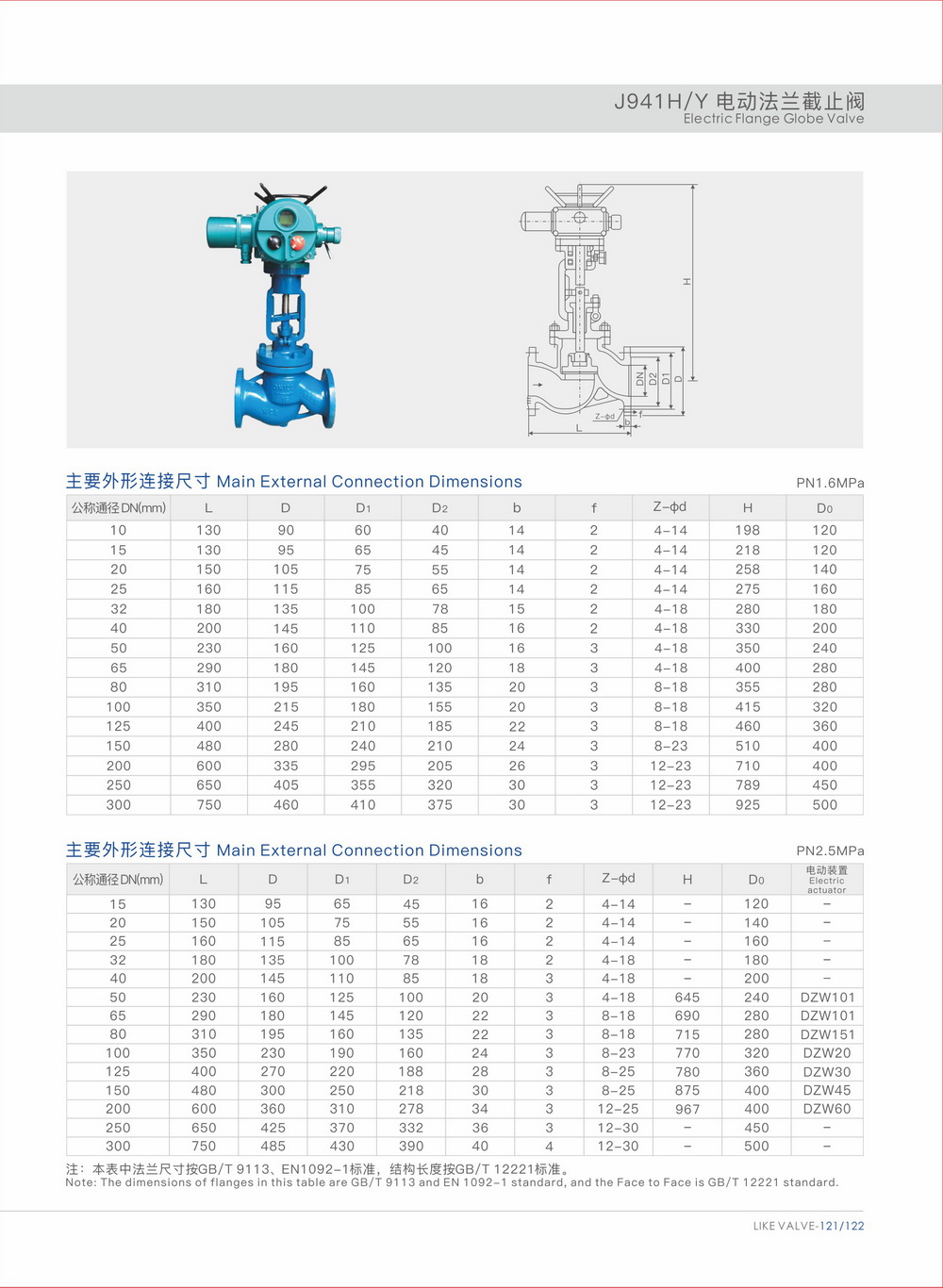

2. nominal diameter and nominal pressure

Ensure that the nominal diameter and nominal pressure of the selected valve meet the system design requirements to ensure the normal operation and safe use of the valve.

3. Connection method

Choose the appropriate valve connection form based on the pipeline connection method, such as flange connection, butt welding connection, etc.

4. Driving method

Choose appropriate driving methods based on operational requirements and environmental conditions, such as electric, pneumatic, etc. Electric drive is suitable for remote control and automation systems.

5. Sealing performance

Ensure that the sealing performance of the valve meets engineering requirements and avoid leakage issues. You can check the leakage rate data and technical specifications of the valve manufacturer.

6. Service life

Consider the service life of the valve and choose products that are reliable in quality and easy to maintain. Understand the after-sales service and maintenance support of valve manufacturers.

4、 Conclusion

Choosing a suitable electric flange globe valve is a comprehensive decision-making process that requires full consideration of the usage environment and working conditions. By precise selection, it can be ensured that the valve has good performance and reliability in actual operation, thereby improving the operational efficiency and safety of the entire system. I hope this article can provide useful guidance for engineers when choosing electric flange globe

valves.