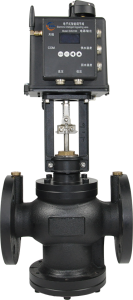

Main technical parameters of dynamic balance intelligent valve

�

Nominal diameter: DN32 ~ DN300�

Nominal pressure: PN1.6MPa

Connection mode: flange connection

Medium temperature: – 20 ~ 150 ¡æ�

Applicable media: steam, water, heat transfer oil, concentration ¡Ü 50% glycol solution

Leakage rate: 0-0.02% kVs

Flow characteristics: equal percentage flow characteristics

Material of main parts

Valve body: ductile iron en-gjs-400-18 (G40)

Stem: stainless steel (304)

Valve core: stainless steel (304)

Sealing ring: PTFE + carbon fiber

Flow characteristics

| caliber | Kv value m 3 / h | Stroke length£¨mm£© |

| DN32 | 10 | 20 |

| DN40 | 12 | |

| DN50 | 31 | |

| DN65 | 49 | |

| DN80 | 78 | |

| DN100 | 124 | 20/40 |

| DN125 | 200 | 40 |

| DN150 | 300 | |

| DN200 | 450 | |

| DN250 | 630 | |

| DN300 | 1200 | 40/100 |

Flow curve

Main performance parameters

| project | parameter | project | parameter |

| caliber | DN32-DN200 | Driving power supply | 24V/220V |

| Rated pressure | 1.6MPa | Working environment temperature | -20¡æ~80¡æ |

| Applicable medium | Water / steam | Opening accuracy | 1% |

| Applicable temperature | -20~150¡æ | Pressure / differential pressure / temperature control accuracy | 0.5% |

| Main materials | Valve body: nodular cast iron / valve core stem: 304 stainless steel | Flow control accuracy | 3% |

| Actuator type | Intelligent straight stroke | Communication mode | Modbus485/0-10V/GPRS |

| Protection level of actuator | IP65 | Display function | Opening, pressure, differential pressure, temperature, temperature difference, flow |

| Actuator input / output signal | 0-10V/4-20mA | control function | Opening control, pressure control, differential pressure control, temperature control, temperature difference control, flow control |

| Main actuator materials | Die casting aluminum |

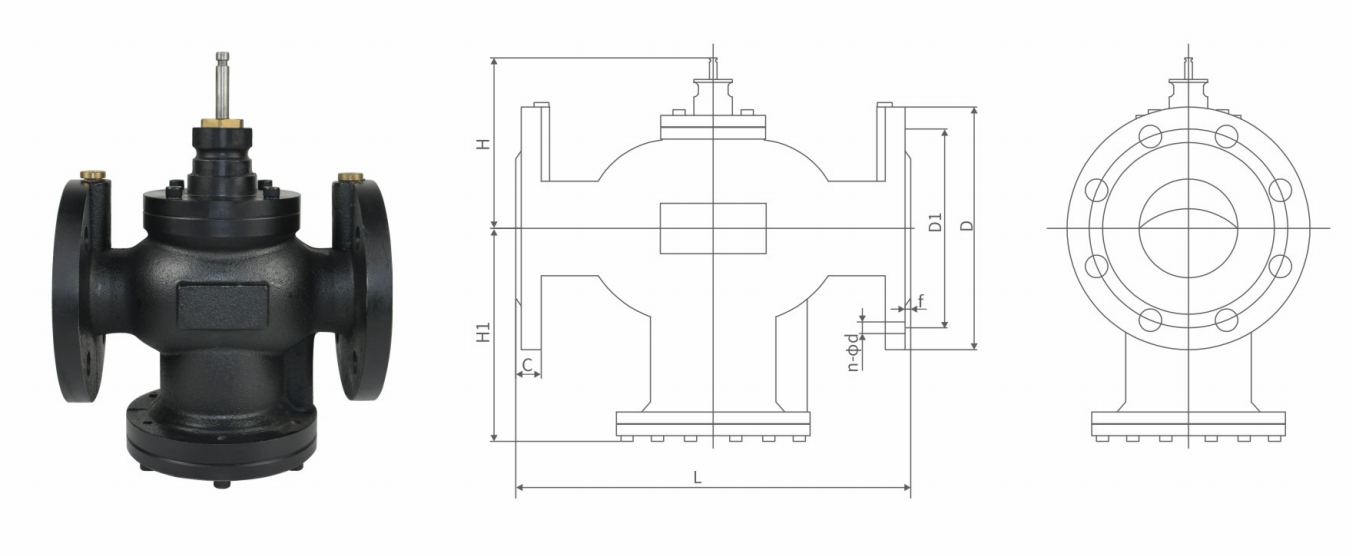

Drawing of dynamic balance intelligent valve

Main dimension table

| caliber | L | D | D1 | n-¦µd | f | c | H | H1 |

| DN32 | 180 | 140 | 100 | 4-18 | 3 | 18 | 165 | 110 |

| DN40 | 200 | 150 | 110 | 4-18 | 3 | 18 | 165 | 115 |

| DN50 | 230 | 165 | 125 | 4-18 | 3 | 20 | 190 | 125 |

| DN65 | 290 | 185 | 145 | 8-18 | 3 | 20 | 209 | 142 |

| DN80 | 310 | 200 | 160 | 8-18 | 3 | 20 | 209 | 154 |

| DN100 | 350 | 220 | 180 | 8-18 | 3 | 22 | 229 | 182 |

| DN125 | 400 | 125 | 210 | 8-18 | 3 | 22 | 268 | 220 |

| DN150 | 480 | 285 | 240 | 8-22 | 3 | 24 | 292 | 245 |

| DN200 | 600 | 340 | 295 | 12-22 | 3 | 24 | 301 | 318 |

Product advantages

�

1. Compared with the traditional casting process, iron grinding and sand coating process has the advantages of uniform wall thickness, no porosity, high material density and more refined appearance.

2. The stainless steel valve seat is cast in one time, which is not deformed in processing. After long-time high temperature use, there is no leakage between the valve seat and the valve body.

3. The V-ring is used for the valve stem seal, which makes the seal more compact when preheating. The quick seal component design makes the replacement of the seal very convenient under special circumstances.

4. The secondary treatment after the production and processing of the valve stem can achieve the mirror effect and ensure the service life and sealing performance.

5. The sealing ring is made of PTFE and carbon fiber, so it has better wear resistance, temperature resistance and corrosion resistance. 6. The paint surface uses spraying line and drying equipment uses resin material, which has strong adhesion and good anti-corrosion effect, and the gloss of valve body has been significantly improved.�

7. Excellent regulation performance, realize proportional integral linear regulation.

8. Accurate control accuracy, valve control error within 5%.�

9. Function switching is realized online. The intelligent function program is written into the electric installation program. After the function switching is completed, different sensors can be connected to the electric installation.