Valve commonly used in English shorthand power station valve maintenance precautions

Common abbreviations for valves Full abbreviations Full abbreviations BB bolted bonnet OS”> Full abbreviations full abbreviations BB bolted bonnet OSY open rod bracket type BC bolted bonnet PBE two end flat port OSY yoke open rod external thread TRIM TRIM TRIM BI-ECC double eccentric PE flat port BLE large end bevel PL plate flat weld BW butt weld PPL counterposition polyphe C.A corrosion margin PSB Pressure seal bonnet CALC calculation (wall thickness) PSC pressure seal bonnet CON concentric PSE small end flat end C.S carbon steel RED Reduced diameter DN Nominal diameter RF convex mesa DSAW Double-sided submerged arc welding RJ ring connection surface ECC eccentric TB threaded connection bonnet EFW electrofusion welding TBE threaded FE concave surface FLG FLanges THR thread GALV galvanized TOE one end thread GRAF Flexible graphite Tri-ECC three eccentric Gr grade SAW submerged arc welding HEX HEX SMLS seamless IR inner positioning ring SO with neck flat welding LR Long radius SR short radius ME convex STL STL alloy NPT60° Taper pipe thread S.S stainless steel OCR octagonal ring gasket SW socket welding O.D OD WN with neck butt welding OR external positioning ring

Maintenance precautions for power plant valves

Reliability, tightness, strength, as well as life and stiffness are the standards to evaluate whether the quality of power station valves is qualified. Because the valve of the power station plays an irreplaceable role in the whole power system, it is necessary to choose the valve with high quality and stable performance. However, in the actual use of the valve process, there are still many problems and defects of the power station valve, valve quality standards do not meet the requirements of the relevant standards and specifications, the valve manufacturing lack of scientific and reliable, the power station valve control system also has some faults. The existence of these problems seriously restrict the use of power station valves, thus hindering the long-term and reliable development of the power industry.

?

Damage to the gate

Gate is an important part of gate valve, therefore, in order to make the role of the gate valve to get effective play, it is necessary to attach great importance to its sealing, and in the production or maintenance of key components. In the process of using the ram, the force is mainly derived from the tensile force and compressive force, in addition, there is the erosion and impact caused by the fluid. For the sealing surface, the extrusion force and friction force are the pressure. The pressure of gate is residual stress and static pressure, where residual stress is affected by manufacturing factors, static pressure is affected by valve seat and liquid. According to the force analysis, the diversity and complexity are the characteristics of the ram, and the ram will be damaged when it is subjected to heavy external load. At the same time, under the influence of all the forces, the liquid is strengthened, and then corrodes the seal body of the gate, reduces the seal of the gate, which leads to the damage of the gate.

Failure of the system

In the valve accident, due to the valve control system failure caused by major accidents accounted for a large proportion. Through research and analysis, the system failure, mainly because of the lack of rationality and scientific design of valve opening, transmission structure is not flexible enough, and stroke is not accurate and so on, these are the direct factors affecting the valve control system failure, especially the impact on its vibration and strength is particularly obvious. Valve opening design is closely related to the orderly development of production, and special attention should be paid to it. At present, the research on opening is increasingly critical, and gradually become the main problem of research. In the transmission mechanism, with the continuous development and innovation of science and technology, the intelligent valve is put forward. It can realize its own half section according to different working conditions, and has the function of self-regulation and real-time characteristics, which ensures the flexibility of the valve to a great extent. Digital positioner is the first part of the intelligent valve, with the help of microprocessor, improve the accuracy of valve actuator positioning, and the valve related data monitoring and recording.

The question of strength

The strength and service life of the valve is determined by the number of times the unit starts, and the speed regulation of the valve is the most direct influence. In order to make the valve work, it is necessary to focus on the strength, tightness and service life of the valve to ensure. In general, once the unit is frequently started, the valve will not be able to meet the actual needs of operation, which is mainly caused by the insufficient strength of the valve. In the design of the valve, to be based on the basic load, in the formal design, only pay attention to the temperature, static pressure and creep and other influencing factors, did not consider the fatigue life problem, which leads to the valve design can not meet the actual application needs. Therefore, the fatigue life factor must be taken into account in the design to ensure that the design condition is consistent with the operating condition, so as to extend the service life of the valve. In view of some problems and defects existing in the valve of the power station, the relevant personnel have conducted in-depth research and analysis, and put forward the corresponding maintenance countermeasures. At the same time, the process of the valve of the power station has been discussed, which has made a significant contribution to ensure the effective use of the valve of the power station.

The maintenance strategy

In order to ensure the reliability and safety of the power station valve in the operation process, it must be regularly maintained to ensure the normal operation of the power station valve at all times. Through the analysis and research of relevant personnel, the application method of the valve is summarized, that is, safe operation and simplified maintenance, only to achieve these two standards, to ensure the effectiveness of the utility valve, so as to ensure the healthy and safe development of the power industry.

The study of the problem

According to the analysis of the actual application process of the power plant valve, the main problems in control, strength, and vibration are the valve. Through the narrative above knowable, power station valve problems that exist in the diversity and complexity, but its homogeneity, the causes of the formation of these problems in order to deal with these problems, the influence factors of the relevant personnel of power station valve * * * and system analysis, then the essence of the problems of the valve has the understanding and mastery. Among them, the strength, static, dynamic, wear resistance and stability factors are studied.

Monitoring of valve

At this stage for the solution of the valve problem, the improvement of the valve control system and the real-time fault diagnosis abroad have been focused on, in this context, for the valve manufacturers have brought great economic benefits, so as to promote the rapid development of related industries. With the continuous improvement of electronic information technology, the electric power industry of our country actively uses advanced online monitoring technology, and the application state of the valves is dynamically monitoring in real time, thus obtaining the operating data of the valves. At the same time, the operation of the valve is improved, the maintenance times of the valve are reduced, the maintenance cost is saved, and the economic benefit is improved. It can be said that the dynamic online monitoring of valves has laid a solid foundation for the rapid development of the valve industry, so that it is always consistent with the international technical level.

Technology analysis

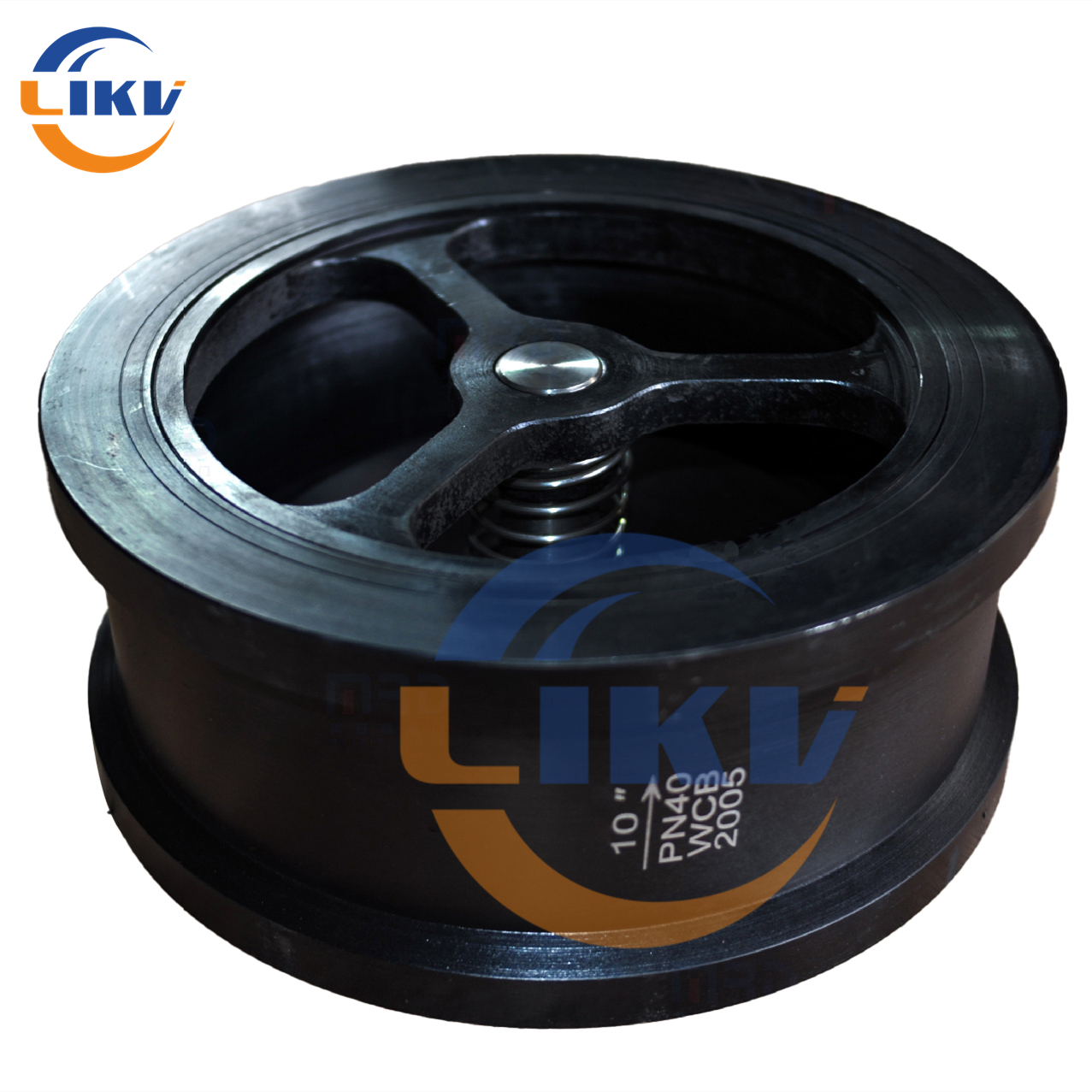

The power station valve is mainly realized by the valve disc movement, and the movement has different forms, at the same time, the valve stem opening and closing has a short stroke, so the reliability of cutting is high. The disc of globe valve is made of cast steel or forged steel. When the disc is opened, the valve seat and the sealing surface of the disc will be separated, so that the mechanical wear of the sealing surface is relatively small and the sealing surface has good sealing property. However, the disadvantage of the sealing surface is the adhesion of particles, and the valve disc needs to be made into a porcelain ball or steel ball. In general, the disc and seat in the globe valve are easy to replace and maintain, and the valve and pipeline can be welded in one piece without disassembly of the entire valve.

Post time: Jul-26-2022