Valve commonly used non-metallic materials check the connection mode between the electric actuator and each valve

Ethylene propylene rubber seat rated temperature range is -28 ℃~120℃. EPDM stands for terpolymer of ethylene, propylene, and diene, commonly called EPT Nordell. Excellent ozone resistance and weather resistance, good electrical insulation performance, good resistance to polar capacitors and inorganic media. Therefore, it can be used in HVAC industry, water, phosphate ester, alcohol, ethylene glycol, etc. Ethylene propylene rubber SEATS ARE NOT RECOMMENDED FOR USE IN HYDROCARBON organic SOLVENTS AND OILS, chlorINATED HYDROCARBONS, turpentINE, or other petroleum OILS.

Valve commonly used non-metallic materials

Buna-n, nitrile rubber

Nitrile rubber seat rated temperature range is -18 ° C to 100 ° C. Also commonly called, NITRILE, or HYCAR. It is a universal rubber material suitable for water, gas, oil and grease, gasoline (except gasoline with additives), alcohol and ethylene glycol, liquefied petroleum gas, propane and butane, fuel oil and many other media. It also has good wear resistance and deformation resistance. Food grade (FG) nitrile rubber seat rated temperature range is -18℃ to 82℃. Its composition conforms to CFR Standard Part 21, Section 177.2600. It can be used in the same way as regular nitrile rubber but requires FDA approval.

Ethylene propylene rubber EPDM

Ethylene propylene rubber seat rated temperature range is -28℃~120℃. EPDM stands for terpolymer of ethylene, propylene, and diene, commonly called EPT Nordell. Excellent ozone resistance and weather resistance, good electrical insulation performance, good resistance to polar capacitors and inorganic media. Therefore, it can be used in HVAC industry, water, phosphate ester, alcohol, ethylene glycol, etc. Ethylene propylene rubber SEATS ARE NOT RECOMMENDED FOR USE IN HYDROCARBON organic SOLVENTS AND OILS, chlorINATED HYDROCARBONS, turpentINE, or other petroleum OILS.

Food grade ethylene propylene rubber seat rated temperature range is -28℃~120℃. Its composition conforms to CFR Standard Part 21, Section 177.2600. It can be used in the same way as regular nitrile rubber but requires FDA approval.

PTFE PTFE

Teflon seat rated temperature range is -32 ° C to 200 ° C. Excellent resistance to high temperature and chemical corrosion. Because of the high density of polytetrafluoroethylene, excellent permeability, but also can prevent the corrosion of most chemical media.

Conductive TEFLON IS A MODIFIED TEflON product that allows current to pass through the lining to REMOVE THE INSULATION OF THE TEflON. Because of its conductivity, conductive polytetrafluoroethylene can not be tested by electric spark.

Reinforced polyteflon RTFE

RTFE is a modification of PTFE material. Although the friction coefficient of pure PTFE is very low (0.02~0.04), but the wear is great, and because of its easy creep, poor mechanical properties, low bearing capacity, poor dimensional stability and other characteristics, as a friction material has great limitations. Only modification, through the method of material composite to meet the special requirements of wear-resistant sealing materials in all walks of life, in improving the wear resistance of PTFE, can be mixed with some wear-resistant substances such as glass fiber, carbon fiber, graphite, molybdenum disulfide, bronze powder and some organic compounds, The mesh joints are formed in the PTFE layered structure to improve the stiffness, thermal conductivity, creep resistance, and wear resistance.

Fluorine rubber Viton

The rated temperature of fluorine rubber seat is -18℃~150℃. Viton is a registered trademark of DuPont Company, and Fluorel is a registered trademark equivalent to fluorine rubber of 3M Company. This material has high temperature resistance and excellent chemical corrosion resistance. Suitable for hydrocarbon products, low concentration and high concentration of mineral acids, but not in steam media and water (poor water resistance).

Ultra high molecular weight polyethylene UHMWPE

Ultra-high molecular weight polyethylene seats are rated from -32 ° C to 88 ° C. This material has better low temperature resistance than PTFE, but still has excellent chemical resistance. Uhmwpe also has good wear resistance and corrosion resistance, and can be used in high wear resistance situations.

Silicone copper rubber Silicone

Copper silicone rubber is a polymer with organic groups, whose main chain is composed of silicon and oxygen atoms. The rated temperature ranges from -100 ° C to 300 ° C. It has good heat resistance and temperature resistance, excellent electrical insulation performance and large chemical inertness. Suitable for organic acid and low concentration of inorganic acid, dilute alkali and concentrated alkali. Disadvantages: low mechanical strength. Post vulcanization treatment is required.

Graphite Graphite

Graphite is a crystal of carbon, is a non-metallic material, silver gray color, soft quality, with metallic luster. Mohs hardness is 1~2, specific gravity is 2.2~2.3, and bulk density is generally 1.5~1.8. It has high temperature resistance, oxidation resistance, corrosion resistance, thermal shock resistance, high strength, good toughness, high self-lubricating strength, strong thermal conductivity, electrical conductivity and other unique physical and chemical properties. It has special oxidation resistance, self-lubricity and plasticity at high temperature, and good electrical, thermal and adhesion properties. It can be used as filler or performance IMPROver for rubber, plastic and various composite materials to improve the wear resistance, compression resistance or conductivity of materials. The valve gasket, packing and seat are usually made of graphite.

Graphite of high melting point, to 3000 ℃ under the vacuum is to begin to soften tends to melt state, graphite evaporated sublimation to 3600 ℃, the general material under the high temperature strength decreases gradually, while the graphite in the heated to 2000 ℃, its strength is normal temperature double instead, but the difference of oxidation resistance of graphite oxidation rate was gradually increased with the temperature.

The thermal conductivity and electrical conductivity of graphite is quite high, its conductivity is 4 times higher than stainless steel, 2 times higher than carbon steel, 100 times higher than the general non-metal. Its thermal conductivity, not only more than steel, iron, lead and other metal materials, but also with the temperature increases the thermal conductivity decreases, which is different from the general metal materials, at very high temperature, graphite even tends to adiabatic state. Therefore, under ultra-high temperature conditions, graphite insulation performance is very reliable. Graphite has good lubricity and plasticity, graphite friction coefficient is less than 0.1, graphite can be developed into permeable light sheet, in the first phase of graphite hardness is very large, even with diamond tools are difficult to process. Graphite has chemical stability, acid resistance, alkali resistance, resistance to organic solvents corrosion. Due to the above unique excellent properties of graphite, in modern industrial use increasingly excellent.

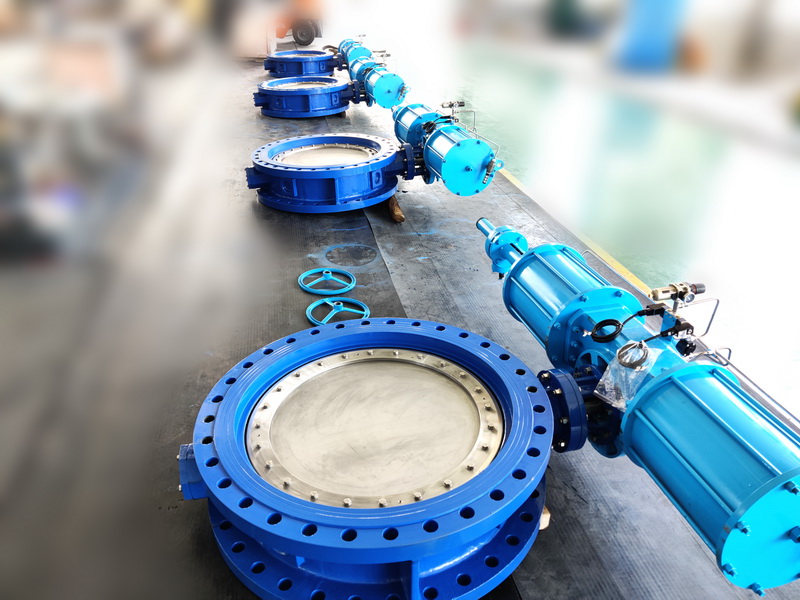

The connection mode between the electric actuator and each valve

The electric actuator is mostly matched with the valve, which is used in the automatic control system. There are many kinds of electric actuators, which are different in the mode of action. For example, the angular stroke electric actuator is the output angular torque, while the straight stroke electric actuator is the output displacement thrust. The type of electric actuator in the system application should be selected according to the work needs of the valve.

The connection method

I. Flange connection:

This is the most common form of connection used in valves. According to the shape of the joint surface, it can be divided into the following:

1. Smooth type: used for valves with low pressure. Convenient processing

2, concave and convex type: high working pressure, can be used in the hard washer

3. Tenon and groove type: gasket with larger plastic deformation can be used in corrosive media, and the sealing effect is better.

4, trapezoidal groove type: with oval metal ring as a washer, used in the working pressure of 64 kg/cm2 valve, or high temperature valve.

5, lens type: the washer is a lens shape, made of metal. For high PRESSURE VALVES WITH WORKING PRESSURE OF 100 kg/CM2, or high temperature valves.

6, O ring type: This is a relatively new flange connection form, it is developed with the appearance of various rubber O ring, it is in the sealing effect of the connection form.

Two, thread connection:

This is a simple connection method and is often used with small valves. There are two further cases:

1, direct sealing: internal and external threads directly play the role of sealing. In order to ensure that the joint does not leak, often with lead oil, linoleum and PTFE raw material filled; Ptfe raw material belt, the use of increasing popularity; This material has good corrosion resistance, sealing effect, easy to use and store, disassembly, can be completely removed, because it is a non-viscous film, much superior to lead oil, linoleum.

2. Indirect sealing: the force of screw tightening is transferred to the washer between the two planes, so that the washer plays the sealing role.

Three, card sleeve connection:

The connection and sealing principle of the clamping sleeve is that when the nut is tightened, the clamping sleeve is under pressure, so that its edge bites into the outer wall of the pipe, and the clamping sleeve outer cone is close to the joint body cone under pressure, so it can reliably prevent leakage.

The advantages of this form of connection are:

1, small size, light weight, simple structure, easy disassembly;

2, strong connection, wide range of use, can withstand high pressure (1000 kg/cm2), high temperature (650℃) and shock vibration

3, can choose a variety of materials, suitable for corrosion prevention;

4, machining accuracy requirements are not high; Easy to install at high altitude.

The clamping sleeve connection form has been used in some small diameter valve products in China.

Four, clamp connection:

This IS A QUICK CONNECTION METHOD that REQUIRES ONLY TWO BOLTS AND IS SUITABLE FOR frequently removed low PRESSURE VALVES.

Five, internal self-tightening connection:

Above all kinds of connection forms, are the use of external force to offset the pressure of the medium, to achieve sealing. The following describes a form of self-tightening connection using medium pressure. Its sealing ring is installed in the inner cone, with the medium opposite side into a certain Angle, medium pressure to the inner cone, and transferred to the sealing ring, in a certain Angle of the cone surface, produce two components, one parallel to the center line of the valve body outward, the other pressure to the inner wall of the valve body. The latter component is the self-tightening force. The greater the medium pressure, the greater the self-tightening force. So this type of connection is suitable for high pressure valves. It saves a lot of material and labor than flanged connection, but also requires a certain amount of preload, so that the pressure in the valve is not high, reliable use. The valve made of the principle of self tight sealing is generally a high pressure valve.

There are many forms of valve connection, for example, some do not have to remove the small valve, welded together with the pipe; Some non-metallic valves, using socket connection, and so on. Valve users should be treated according to the specific conditions.

Post time: Jul-29-2022